Leave Your Message

As the textile industry evolves, the design and functionality of the Textile Bobbin Machine are changing rapidly. These machines are crucial for efficiently winding yarn, which directly affects production quality. New trends are emerging that focus on sustainability and automation, reflecting the growing demand for environmentally friendly practices.

Innovations in the Textile Bobbin Machine strive to enhance performance and reduce energy consumption. Features like smart technology integration allow for real-time monitoring. This can help manufacturers identify issues before they escalate. Some advancements, however, may not be practical for every facility. Smaller operations might struggle to adopt high-tech solutions.

While the future looks promising, challenges remain. Cost is a significant factor. Investing in these advanced machines might not be feasible for all. Balancing innovation with affordability requires careful consideration. Therefore, as the industry progresses, it is essential to evaluate both the benefits and limitations of each new trend in Textile Bobbin Machine development.

The textile industry faces rapid changes. For 2026, bobbin machine innovations focus on automation and efficiency. According to recent market analysis, automated bobbin winding machines can increase production speed by up to 30%. This shift is largely driven by the need for higher output and lower labor costs. As manufacturers seek to remain competitive, investment in smart technology becomes essential.

Emerging technologies like IoT-enabled machines provide real-time data. They enhance monitoring and maintenance procedures. Predictive maintenance minimizes downtime, ensuring continuous operation. Reports show that companies using smart machines experience a reduction in operational costs by around 20%. However, this transition raises challenges. Many manufacturers struggle to integrate new systems with existing workflows.

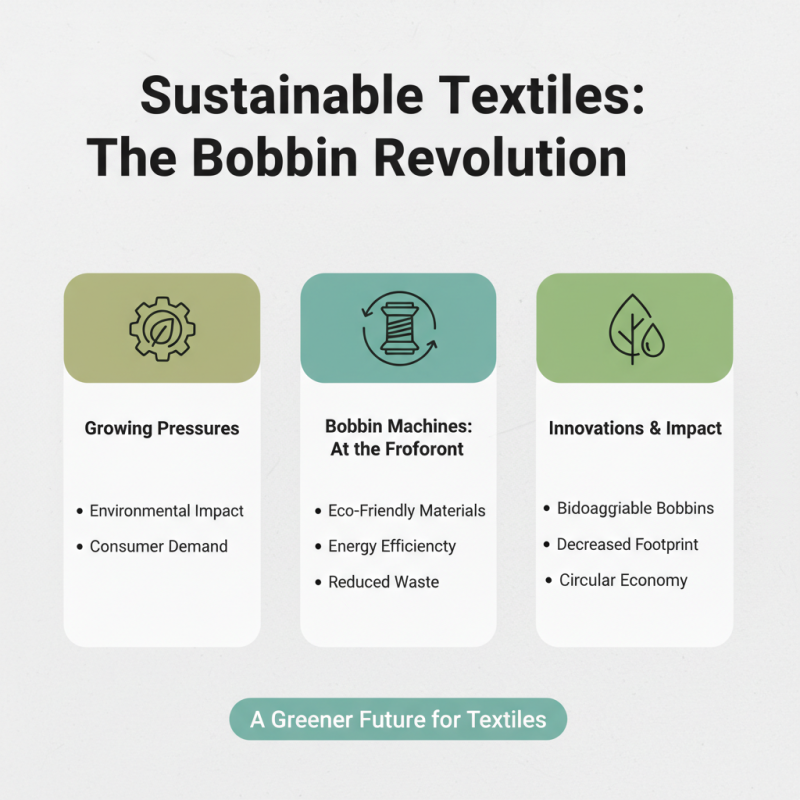

Another trend is the use of eco-friendly materials. Sustainable bobbins made from biodegradable plastics are gaining traction. This shift addresses environmental concerns, aligning with consumer preferences. Yet, developing these materials remains complex. Balancing sustainability and performance is a critical task for engineers. The industry needs to rethink design conventions for these innovations to excel.

The textile industry faces growing pressures regarding sustainability. Bobbin machines are at the forefront of this shift. Designers are focusing on eco-friendly materials and processes. They're emphasizing energy efficiency and reducing waste. Innovations include using biodegradable materials for bobbins. These advances can decrease the industry's environmental footprint.

However, adopting sustainable practices is not easy. Many manufacturers struggle with the initial costs. Transitioning to greener technologies can be challenging. Some machines still rely on outdated designs, limiting efficiency. This gap reveals the need for a more comprehensive approach. Research and development must focus on sustainability without sacrificing performance.

Trends show a broadened interest in recycling old machine parts. This can minimize waste and create a circular economy in textiles. Yet, the commitment to sustainability often varies among companies. Not every manufacturer is ready to invest. Consequently, the industry must expand discussions around these innovations. Efforts should include collaboration across sectors to drive real change.

The textile industry is experiencing a wave of efficiency innovations in bobbin machines. These machines are now designed with advanced automation features. They can change bobbins more quickly, which minimizes downtime during production runs. Operators benefit from user-friendly interfaces, which streamline the setup process. New technologies allow for better monitoring of thread tension, leading to fewer errors.

One noteworthy trend is the adoption of predictive analytics in bobbin machines. This allows manufacturers to anticipate maintenance needs. However, the implementation phase can be challenging. Not all operators are trained to adapt to these new systems, which can slow down production. Finding the right balance between automation and hands-on oversight is crucial.

While innovations are promising, they sometimes raise questions about reliability. Advanced machines can malfunction, leading to production halts. Additionally, the cost of investment is high. Smaller manufacturers may struggle to keep up. It's essential to evaluate whether the gains in efficiency truly outweigh these risks and costs. A thoughtful approach is needed to harness these innovations effectively.

In 2026, the textile industry will witness significant transformations in bobbin machine technology, particularly in smart features. Automation and IoT integration are at the forefront. These advancements allow machines to communicate and operate with minimal human intervention. According to reports, the global smart textile market is expected to reach $6.5 billion by 2026. This growth demonstrates the industry's shift towards efficiency.

Smart bobbin machines offer real-time monitoring. Sensors track thread usage and tension. This feature prevents waste and improves quality. Yet, implementation can be challenging. Small manufacturers may struggle with the cost of modernization. The initial investment can deter many companies. It's essential to evaluate both short-term expenses and long-term benefits.

Tips: Focus on gradual upgrades. Begin with integrating basic IoT features. Train staff on new systems to ensure effective usage. These steps can ease the transition. As the market evolves, staying updated is crucial. Embrace changes cautiously and reflect on their impact. Balancing innovation with practicality is vital.

This chart illustrates the percentage of textile bobbin machine features expected to integrate automation and IoT by 2026. As the industry evolves, these trends highlight the focus on efficiency and connectivity.

The textile bobbin industry faces unique challenges. Striking a balance between demand and innovation is critical. Manufacturers are adapting to evolving needs. Consumer expectations are higher than ever. They want durability and efficiency in textile products.

Efficiency is non-negotiable. Businesses must streamline production methods. Traditional bobbin systems may not meet current demands. Using automated systems can help adapt to market needs. However, transitioning comes with its own set of challenges. Training staff is essential yet may spark resistance.

Tips: Invest in employee training. A well-informed workforce can enhance productivity. Stay updated with industry trends. Attend conferences or webinars. Networking with peers can reveal practical solutions to common problems. Lastly, embrace digital tools for better inventory management.