Leave Your Message

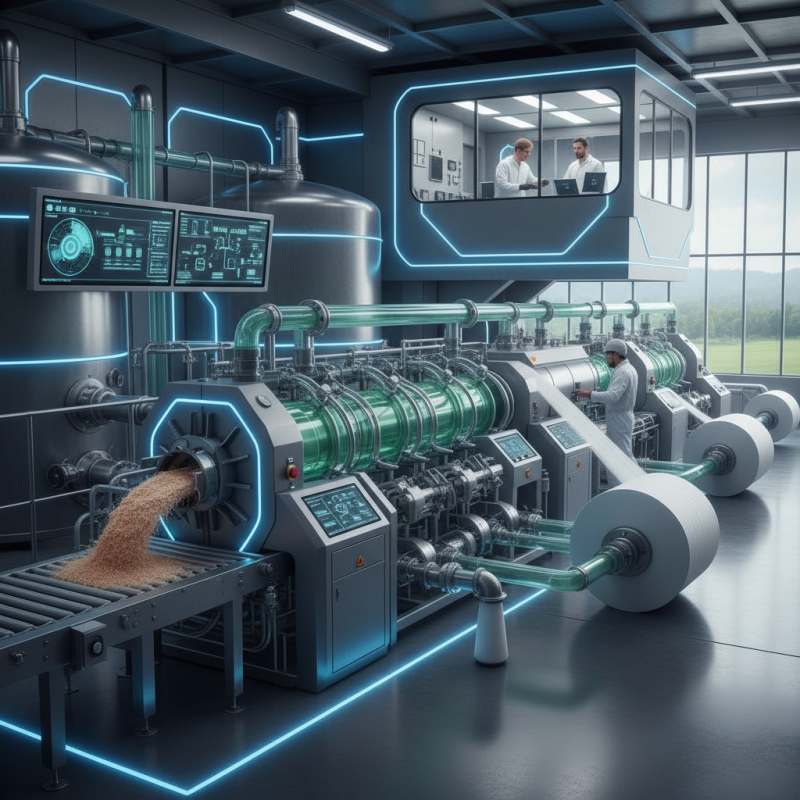

Automatic Lyocell Equipment revolutionizes the textile industry. It simplifies the manufacturing of lyocell fibers from wood pulp. This equipment automates various processes, improving efficiency and reducing waste.

In a world that values sustainability, Automatic Lyocell Equipment stands out. It uses closed-loop systems to recycle solvents, minimizing environmental impact. The machine processes raw materials into high-quality fibers with less water and energy compared to traditional methods.

However, reliance on technology raises questions. Are operators well-trained to handle the equipment? What happens when breakdowns occur? The balance between automation and human oversight must be carefully managed to ensure optimal production.

Automatic Lyocell equipment refers to the machinery used in the production of lyocell fibers. These fibers are derived from wood pulp, making them a sustainable alternative to traditional textiles. The equipment automates several processes, from dissolving cellulose to spinning the fibers. This automation enhances efficiency and reduces human error during production.

The equipment often includes a closed-loop system. This system recycles solvents, minimizing waste. However, this process can be complex and may face technical challenges. For example, maintaining the right temperature and pressure is crucial. If not managed properly, fiber quality can suffer. Operators must keep a close eye on these parameters during production.

Moreover, the equipment needs regular maintenance. Issues like clogs or leaks can arise unexpectedly. These challenges require trained personnel to address them quickly. It's essential to recognize that while automation improves productivity, the human element remains vital for ensuring quality and consistency.

Automatic Lyocell equipment plays a crucial role in the production of Lyocell fibers. These machines streamline the transformation of natural cellulose into a fine, biodegradable fiber. There are several key components that make this process efficient.

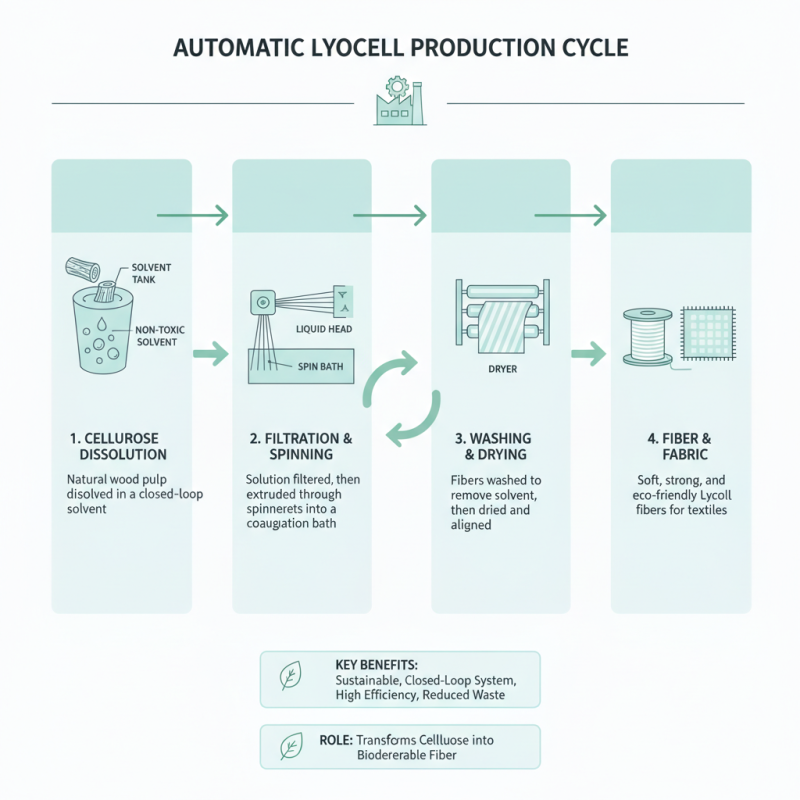

The heart of the equipment is the dissolving unit. It uses solvents to break down cellulose. This unit must maintain precise temperature and pressure for optimal results. The fiber spinning section follows. It transforms the dissolved cellulose into continuous filaments. A spinneret is employed here, creating fibers with uniform thickness. Heating elements play a role in solidifying these fibers as they exit.

Another essential component is the washing unit. This section removes any residual solvents. It ensures that the final product is safe and ready for use. Operators must monitor this stage closely. Any oversight here can lead to quality issues. Lastly, the drying system is critical. It reduces moisture content while preserving fiber strength. Observing how these components interact is vital for continuous improvement in the Lyocell process.

Automatic Lyocell equipment plays a significant role in the fiber production process. This equipment streamlines the manufacturing of Lyocell fibers from wood pulp, utilizing advanced technology to enhance efficiency. The process generally starts with dissolving cellulose in a solvent, which requires meticulous handling.

The equipment operates by carefully mixing and heating the cellulose solution. This step is crucial for ensuring a consistent fiber quality. Once the solution is prepared, it undergoes spinning through spinnerets to form threads. These threads are then coagulated in a bath, resulting in continuous fibers. Observing the entire procedure reveals that even minor inconsistencies can lead to defective products, highlighting the importance of precision.

While technology has improved fiber production, challenges remain. Equipment requires frequent maintenance to avoid breakdowns. Operators must be adequately trained, as mistakes could lead to waste and increased costs. The automation process may also seem daunting, especially for smaller manufacturers. Balancing automation with manual oversight can be a tricky endeavor.

Automatic lyocell equipment offers several advantages to the textile industry. It enhances efficiency significantly. According to a report by the Textile Machinery Association, automated processes can reduce labor costs by approximately 30%. This savings allows companies to invest more in sustainable practices.

Automatic equipment also ensures consistent quality. The precision of these machines minimizes errors. For instance, data from the Fabric and Fiber Industry Report shows that automated systems can lower defect rates by up to 25%. This consistent output is vital in meeting market demands.

**Tip:** Regular maintenance of automatic equipment is crucial. Delays can lead to increased waste and reduced efficiency.

Using automatic Lyocell equipment contributes to environmental benefits. It consumes less water and energy compared to conventional methods. The Eco-Friendly Fibers report highlights that lyocell production can reduce water usage by about 90% compared to cotton. However, it is essential to remain mindful of the long-term environmental impact of machines.

**Tip:** Evaluate the life cycle of your equipment. Investing in machines with lower energy consumption can enhance sustainability over time.

Automatic Lyocell equipment has transformed the textile industry. It simplifies the production of Lyocell fibers. These fibers are cellulosic and derived from wood pulp. The process uses less water and energy compared to traditional methods. However, the technology is not flawless. Some equipment may struggle with consistency in fiber quality.

In textile applications, Lyocell fibers are valued for their softness and biodegradability. They are often used in clothing and home textiles. The equipment allows manufacturers to produce fibers efficiently, meeting market demand. Yet, the calibration of machines needs continuous attention. Improper settings can lead to production issues.

In addition, automatic systems offer scalability. This means small and large manufacturers can benefit. However, the initial investment in technology can be daunting. Companies must weigh costs against potential returns. It is crucial to keep refining processes to ensure efficiency. Adapting to changing trends is another challenge.