Leave Your Message

The landscape of nonwoven fabric production has evolved significantly over the last decade, with the Automatic Spunlace Line emerging as a game-changer in the industry.

According to a recent market analysis by Smithers Pira, the global nonwoven fabric market was valued at USD 50 billion in 2021 and is projected to reach USD 70 billion by 2026, driven by advancements in production technology and increasing demand across various sectors including hygiene, medical, and automotive.

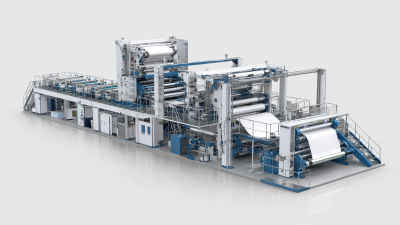

The Automatic Spunlace Line, which utilizes high-pressure water jets to entangle fibers, offers enhanced efficiency, superior fabric quality, and reduced operational costs compared to traditional methods.

This innovative line not only accelerates production rates but also minimizes waste, aligning with the industry's push towards sustainability.

As manufacturers adopt these advanced systems, the future of nonwoven fabric production looks promising, paving the way for more versatile applications and improved performance in end products.

The landscape of nonwoven fabric production has evolved significantly over the last decade, with the Automatic Spunlace Line emerging as a game-changer in the industry.

According to a recent market analysis by Smithers Pira, the global nonwoven fabric market was valued at USD 50 billion in 2021 and is projected to reach USD 70 billion by 2026, driven by advancements in production technology and increasing demand across various sectors including hygiene, medical, and automotive.

The Automatic Spunlace Line, which utilizes high-pressure water jets to entangle fibers, offers enhanced efficiency, superior fabric quality, and reduced operational costs compared to traditional methods.

This innovative line not only accelerates production rates but also minimizes waste, aligning with the industry's push towards sustainability.

As manufacturers adopt these advanced systems, the future of nonwoven fabric production looks promising, paving the way for more versatile applications and improved performance in end products.

Automatic spunlace lines have revolutionized the nonwoven fabric manufacturing process by introducing efficiency and precision in fabric production. These advanced systems employ high-pressure jet streams to entangle fibers, creating robust and versatile nonwoven materials suitable for a multitude of applications. By automating this process, manufacturers can achieve consistent quality and reduce labor costs, all while speeding up production rates. This technological innovation meets the rising demand for nonwoven fabrics in various sectors, such as hygiene, medical, and filtration.

The market for nonwoven fabrics is diverse, with several types categorized by function and technology—dry laid, spunbond, and wet laid processes are among the prominent methods. Each technology provides different characteristics to the finished products, contributing to specialized applications that cater to specific end-use industries. Among these, hygiene products and medical supplies represent significant growth segments, driven by increasing consumer awareness and healthcare needs. As automatic spunlace lines continue to evolve, they play a crucial role in enhancing the production capabilities and versatility of nonwoven textiles across the global market.

An automatic spunlace line represents a significant advancement in nonwoven fabric production, integrating various key components and technologies that streamline the manufacturing process. At the heart of this system is the high-pressure water jet technology, which entangles fibers without the use of binders, resulting in durable, lightweight fabrics. This innovative approach not only enhances the quality of the end product but also allows for greater design flexibility, enabling manufacturers to cater to diverse markets ranging from hygiene products to industrial applications.

Another critical element of the automatic spunlace line is the advanced control systems that monitor and regulate every stage of production. These systems ensure optimal conditions for fiber entanglement and fabric formation, contributing to uniformity and efficiency. Additionally, automation minimizes human error and reduces labor costs while maximizing output. The integration of smart technology, such as IoT sensors, allows for real-time data collection and process adjustments, further enhancing productivity and maintaining high-quality standards in nonwoven fabric manufacturing.

The automatic spunlace line revolutionizes the production of nonwoven fabrics by streamlining the process from raw materials to finished products. This advanced technology integrates multiple stages, such as fiber feeding, hydroentangling, and drying, to create high-quality nonwoven textiles efficiently. According to a report by Smithers Pira, the global nonwovens market is projected to reach $40 billion by 2024, indicating the significance of efficient manufacturing processes in meeting rising demand.

To illustrate the process flow: it begins with the selection of raw materials, typically synthetic fibers like polyester or polypropylene. These fibers are opened and carded to form a web. The automatic spunlace line then uses a high-pressure water jet to entangle the fibers without the use of binders, resulting in a strong and durable nonwoven fabric. Once the fabric is entangled, it proceeds to drying, where moisture is removed to ensure optimal quality and performance. Recent advancements in automation have enhanced production speeds by up to 25%, as highlighted in a report from Technavio.

Tips: When choosing raw materials, consider the end-use of the nonwoven fabric to optimize performance. Also, monitoring the water pressure during hydroentangling is crucial to ensure the desired fabric strength and texture. Regular maintenance of the system can further enhance efficiency and prolong the lifespan of the equipment.

Automatic spunlace lines are revolutionizing the nonwoven fabric production industry by enhancing efficiency and reducing operational costs. According to a report by Smithers Pira, the global nonwoven fabric market is projected to reach $60 billion by 2028, fueled by increasing demand in sectors such as hygiene, medical, and filtration. Automatic spunlace lines streamline the production process by integrating multiple steps, from feeding raw materials to the finished product, thereby minimizing labor requirements and production time.

One of the most compelling advantages of using automatic spunlace lines is the consistency and quality of the nonwoven fabrics produced. A study by the Nonwovens Industry Association revealed that automated systems can achieve a production efficiency of up to 90%, significantly higher than manual processes. This not only meets the growing demand but also ensures that manufacturers can maintain stringent quality control standards, reducing waste and maximizing profitability.

Tips for optimizing your production with automatic spunlace lines include regular maintenance to prevent downtime and investing in staff training for effective operation. Additionally, consider incorporating real-time monitoring systems to track production metrics, which can help identify bottlenecks and further enhance efficiency. Implementing these practices can lead to sustained improvements in production output and quality.

The evolution of spunlace technology is set to redefine the landscape of nonwoven fabric production, particularly in light of recent initiatives aimed at promoting high-quality development in the consumer goods industry. As manufacturers increasingly seek to meet the growing demands for sustainable and innovative materials, advancements in spunlace technology are emerging as crucial enablers. These developments promise to enhance the efficiency, versatility, and environmental sustainability of nonwoven processes, responding directly to the needs of a market that values both quality and ecological responsibility.

Innovations in automatic spunlace lines are at the forefront of this transformation. By integrating automation and smart technology into production, manufacturers can achieve higher precision, reduce waste, and optimize resource usage. This shift not only streamlines production but also improves product consistency and performance, aligning with the ever-evolving demands of consumers for high-quality, functional materials. As the industry adapts to these trends, the impact on production capabilities and consumer satisfaction is likely to be profound, paving the way for a new era of nonwoven fabric applications across various sectors.

| Dimension | Description | Impact on Production |

|---|---|---|

| Production Speed | High-speed operation allowing faster fabric production. | Increases output while reducing lead time. |

| Material Versatility | Ability to process various fiber types and blends. | Increases product range and adaptability to market needs. |

| Energy Efficiency | Optimized energy consumption for operational processes. | Reduces operational costs and environmental impact. |

| Automation Level | Highly automated processes with reduced manual intervention. | Improves reliability and consistency in production. |

| Quality Control | Integrated quality control mechanisms throughout production. | Ensures high standards of fabric quality and performance. |