Leave Your Message

The textile industry is undergoing significant transformation with innovations such as Automatic Viscose Equipment. This technology enhances production efficiency and meets rising consumer demand for sustainable fabrics. Reports indicate that the global viscose market reached approximately $5 billion in 2022 and is expected to grow by 5% annually. This growth complicates production processes, highlighting the need for advanced machinery.

Automatic Viscose Equipment addresses these challenges by automating key procedures. It minimizes labor costs while maximizing output quality. The integration of automation reduces human errors, thereby increasing reliability. Recent studies show that up to 30% of production downtime is due to manual errors, making automation crucial. However, companies face hurdles in transitioning to fully automatic systems, raising questions about training and costs.

Despite these advantages, reliance on technology can present risks. Over-dependence on Automatic Viscose Equipment may undermine skill development in the workforce. Industries must find a balance between automation and human expertise. Reflecting on these trends is essential for maintaining a sustainable and skilled workforce.

Automatic viscose equipment plays a pivotal role in textile production. It streamlines the manufacturing process, ensuring efficiency. By automating tasks, this equipment reduces human error. It also minimizes labor costs and increases production rates. Many factories rely heavily on this technology to stay competitive.

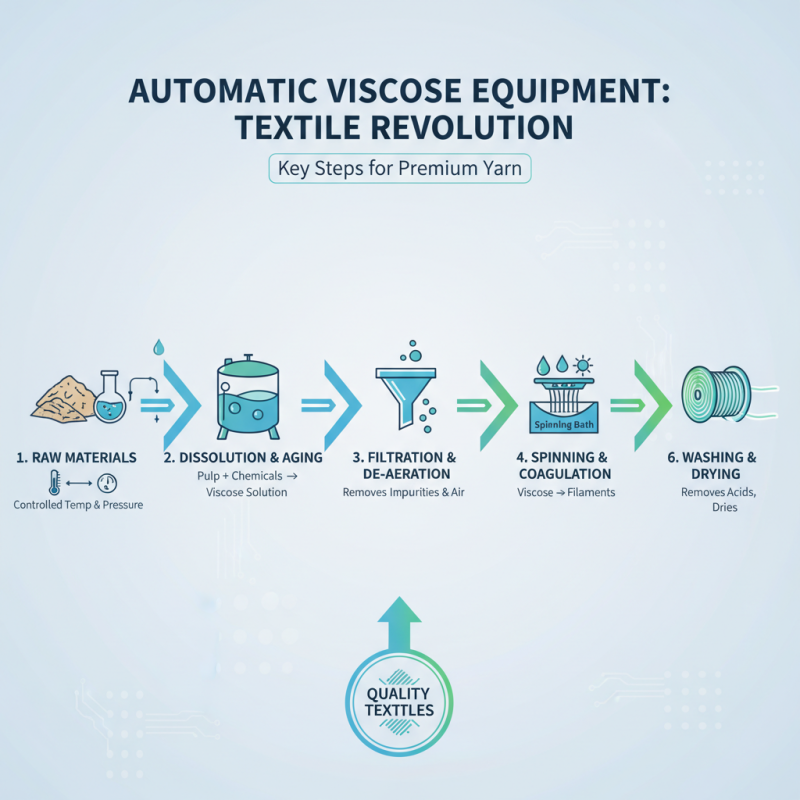

The machinery operates through a series of controlled processes. It dissolves cellulose to create viscose, a key material for fabrics. Precision is crucial here; even slight variations can affect quality. It's not always foolproof; some machines may struggle with consistency. Technicians must monitor operations closely to avoid issues.

With the rise of automatic equipment, adaptability is essential. Manufacturers need to stay updated on technology trends. Regular maintenance of the machines can be a challenge but is necessary for optimal performance. An occasional hiccup in production can lead to delays. Continuous improvement in both technology and processes is vital.

| Feature | Description | Importance |

|---|---|---|

| Automation | Uses automated processes for viscose production. | Increases efficiency and reduces manual labor. |

| Control Systems | Advanced control systems for monitoring operations. | Ensures consistent quality and minimizes errors. |

| Raw Material Processing | Processes cellulose into viscose through chemical treatment. | High-quality raw materials yield better end products. |

| Environmental Impact | Manufactures viscose with less waste and emissions. | Supports sustainable textile production. |

| Maintenance | Regular maintenance schedules ensure optimal performance. | Prolongs equipment life and reduces downtime. |

Automatic viscose equipment plays a crucial role in the textile industry. Its key components work together to create high-quality viscose fibers. One of the main elements is the spinning machine. This machine transforms viscose solution into filament yarn. It has a unique spinning head that regulates the fiber thickness and ensures uniformity.

Another vital component is the drying system. This system removes excess moisture from the fibers. Proper drying is essential for achieving the desired strength and softness. If the fibers are not dried well, it can lead to quality issues. Moreover, the dyeing unit is important for coloring the fibers. It must be carefully calibrated to ensure consistent results with minimal waste.

The control panel is where operators monitor all processes. It allows for adjustments in real-time. However, mastering this technology can be challenging. Operators may encounter issues that require troubleshooting. Regular maintenance is crucial to avoid breakdowns. Each component impacts the overall efficiency, making it vital to understand their functions deeply. Continuous learning is necessary to enhance performance and reduce errors.

Automatic viscose equipment plays a pivotal role in the textile industry. It transforms raw materials into viscose yarn. This process involves several critical steps. Each step requires the right temperature and pressure to ensure quality.

The equipment utilizes a closed-loop system. It starts with dissolving cellulose in chemicals. This solution is then extruded through spinnerets to form fibers. The fibers go through a series of washing and drying stages. Precision is key; any miscalculation can impact the final product. In some cases, the fibers may not fully dry. This can lead to issues in strength and texture.

Understanding the equipment's working principles is essential. Operators must monitor various sensors and gauges. These indicators show pressure levels and solution viscosity. Regular maintenance is crucial but often overlooked. Neglect can lead to equipment failures or inconsistent product quality. Inefficiencies may arise if the system is not adequately calibrated. This creates challenges that manufacturers must continuously address.

Automatic viscose equipment plays a vital role in modern manufacturing processes. It enhances production efficiency while maintaining quality. According to a recent industry report, companies that utilize automatic systems can increase their output by up to 30%. This is significant when production deadlines loom.

Moreover, the equipment minimizes human error, which is a common issue in manual processes. A significant percentage of textile defects arise from such errors. Automated systems reduce variability, ensuring consistent quality in products. However, installing and maintaining this equipment can be costly, sometimes leading to operational strain for smaller businesses.

One must also consider the skill gap in operating sophisticated machinery. Training is essential, yet often overlooked. While technology advances, the workforce must keep pace. Investing in skills development is as crucial as the technology itself. Balancing automation with human expertise may pose challenges, but it can lead to a more resilient manufacturing sector.

The future of automatic viscose equipment is promising. Recent industry reports indicate a projected growth rate of 8% annually in this sector. Innovations focus on efficiency and sustainability. The integration of AI in equipment optimizes production, reducing waste and energy use.

Tips: Consider investing in equipment with smart monitoring features. These can provide real-time data, enhancing decision-making processes.

Moreover, automation minimizes human error. Manufacturers are developing advanced machines that allow seamless production. Enhanced features enable quick adjustments during operations. However, the risk of over-reliance on tech must be considered. An unexpected failure could disrupt the entire process.

Tips: Regular maintenance is crucial for smooth operation. Schedule frequent checks to prevent downtime.

In addition, the eco-friendly aspect of new technologies cannot be overlooked. There's an increasing demand for sustainable practices in textile manufacturing. Companies adopting greener solutions often gain a competitive edge. Exploring biodegradable materials in viscose production could lead to breakthrough innovations, but it may require significant shifts in traditional practices.