Leave Your Message

The textile industry is experiencing rapid transformation, particularly in fiber production. Automatic Lyocell Equipment plays a crucial role in this evolution. According to recent market analysis, the global lyocell fiber market is projected to reach USD 5 billion by 2026. This growth highlights the importance of optimizing manufacturing processes.

Investing in Automatic Lyocell Equipment can enhance efficiency and reduce waste. Advanced technology allows for better resource management. However, many manufacturers still face challenges. Some equipment malfunctions may lead to production downtime. In addition, training workers to operate automated systems can be a slow process.

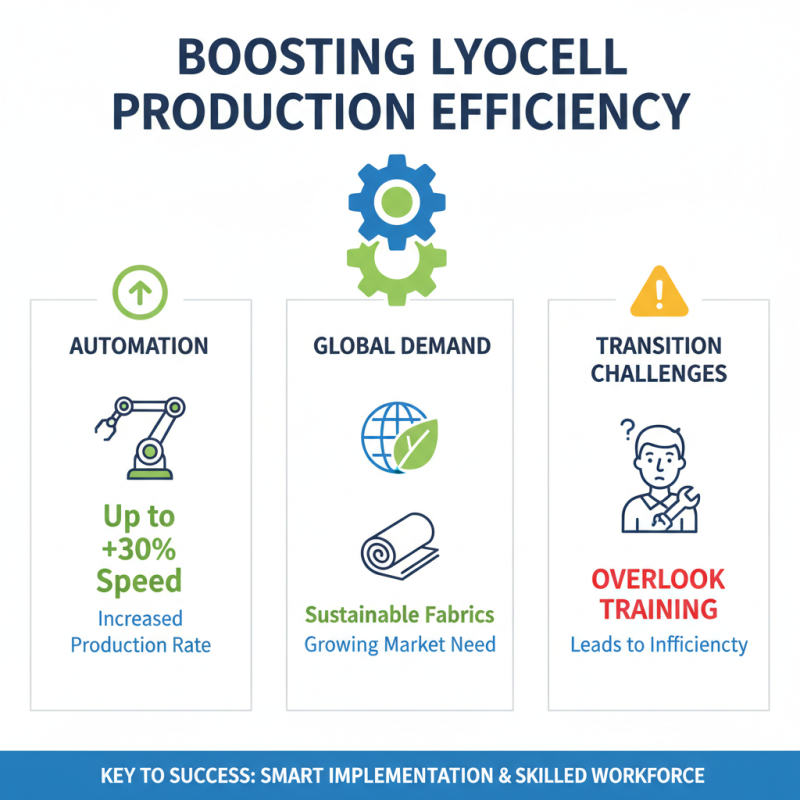

Moreover, sustainability remains a key consideration. The lyocell production process is known for its eco-friendliness, requiring less water and generating fewer emissions compared to traditional textiles. However, reliance on automatic machinery should not overlook the importance of human oversight. Balancing automation and skilled labor is critical for maximizing production efficiency and maintaining product quality.

Lyocell is a fiber made from sustainably sourced wood pulp. The production process is both eco-friendly and efficient. This fiber is often praised for its softness and breathability. These qualities make it a popular choice in the textile industry. Lyocell is biodegradable, adding to its appeal.

When producing Lyocell, the importance of each step cannot be overstated. Proper wood sourcing is crucial; it impacts both sustainability and quality. Choosing the right type of wood can affect the final product's properties. The spinning process requires precision. Even slight deviations can result in defects.

Tips: Ensure your equipment is fine-tuned to minimize waste. Regular maintenance can prevent costly breakdowns. Train staff rigorously to ensure consistency in production. Every detail counts in producing high-quality Lyocell. Small mistakes can lead to larger issues down the line. Efficiency is key, but so is careful attention to detail.

| Equipment Type | Production Capacity (Tonnes/Day) | Energy Efficiency (%) | Water Consumption (Litres/Tonne) | Automation Level (%) |

|---|---|---|---|---|

| Spin Dryers | 20 | 85 | 500 | 95 |

| Fiber Spinning Machines | 30 | 90 | 400 | 98 |

| Washing Units | 25 | 80 | 600 | 85 |

| Drying Equipment | 15 | 88 | 450 | 92 |

| Bale Packing Machines | 35 | 82 | 350 | 97 |

When choosing automatic Lyocell equipment, several key features should guide your decision. Look for machines that prioritize energy efficiency. This feature can significantly lower production costs. Many modern models offer intelligent monitoring systems. They track production data in real-time, allowing for quick adjustments.

Ease of maintenance is another crucial aspect. Equipment that requires minimal downtime keeps your production flow smooth. Pay attention to the accessibility of key components. Handy maintenance features make a big difference in daily operations.

Tips for selecting the right equipment: check for user-friendly interfaces. Operators should feel comfortable using the machines. Training should not be time-consuming. Also, consider the machine's adaptability. Flexibility to handle various production batches is essential.

Lastly, research customer experiences. While manufacturers provide specifications, real-life performance is key. Reviews often highlight unexpected challenges. Be prepared to address those potential hurdles in your operations.

The demand for sustainable textile production is rising.

Lyocell, a fiber made from wood pulp, is gaining popularity. Efficient production of Lyocell relies on advanced equipment.

The automatic systems are designed to enhance productivity and reduce waste.

Top manufacturers in this field focus on innovation. They aim for higher efficiency and lower environmental impact.

These companies invest in technology to streamline processes. However, not all machinery meets high standards.

Some equipment may lack reliability, which can lead to production delays and increased costs.

Maintenance of these systems is crucial. Regular checks can prevent significant issues.

Furthermore, training for operators is often overlooked. Skilled personnel are essential for optimal performance.

Even with advanced machines, human errors can occur. Continuous improvement in this area remains a challenge.

In the realm of Lyocell production, efficiency remains a key driver of success. Recent industry reports indicate that automated processes can boost production speed by up to 30%. This is substantial, considering the increasing global demand for sustainable fabrics. However, the transition to fully automatic systems can be complex. Many manufacturers overlook training needs, resulting in inefficiencies.

Monitoring efficiency metrics is crucial. Metrics such as yield rates and energy consumption provide insight into production effectiveness. In fact, reducing energy consumption by just 10% can lower costs significantly. However, not all automated equipment is created equal. It’s essential to assess specific machinery features. Some equipment may promise high output but may lack energy efficiency.

Tips: Regularly review performance data. Identify bottlenecks promptly. Also, engage staff in the feedback loop. Their insights can guide equipment improvements. Continuous reflection on production methods will ensure you adapt to market changes efficiently. Ultimately, the best practices in Lyocell production lie in balancing efficiency with sustainability.

The future of automatic lyocell equipment technology is promising and evolving. Recent reports indicate a significant growth rate in the lyocell market, estimated at 8.9% annually until 2028. This growth is driven by increasing demand for sustainable textiles. As eco-friendly practices become essential, manufacturers must adapt their equipment to align with these trends.

Advancements in machinery involve automation and artificial intelligence. These technologies enhance production efficiency and minimize waste. For example, automatic adjustment systems can optimize fiber production in real-time. There is also a shift toward fully integrated systems that streamline processes. Nevertheless, challenges include the high initial investment and the need for skilled operators. Manufacturers must find a balance between innovation and cost-effectiveness.

**Tips:** Invest in training for your team. Skilled workers can minimize errors. Regular maintenance of equipment is vital for longevity. Analyze production data to identify areas for improvement. Embrace a culture of continuous learning to stay ahead in this competitive field.