Leave Your Message

The textile industry is undergoing significant transformation, particularly in viscose production. In this context, investments in Automatic Viscose Equipment have become essential. According to Dr. Emily Chen, a leading expert in textile manufacturing, “Efficiency in automatic equipment is crucial for the future of viscose production.”

Automatic Viscose Equipment not only enhances productivity but also reduces environmental impact. For instance, new machines can minimize waste during the production process. However, many manufacturers still struggle with integrating these advancements. It raises the question of how effectively they can adapt to new technologies.

As the demand for eco-friendly textiles grows, so does the need for innovation in Automatic Viscose Equipment. Companies must evaluate their production methods. This involves balancing efficiency with sustainability. The journey towards optimal equipment usage is fraught with challenges, yet it holds immense potential for the industry’s future.

The automatic viscose equipment market is evolving rapidly. In 2026, the focus will be on efficiency and sustainability. Manufacturers are investing in advanced technologies. These innovations promise to reduce waste and energy use. Such improvements directly impact production costs. However, fully implementing these systems can be challenging.

Market trends indicate a growing demand for eco-friendly processes. Companies are seeking machines that minimize environmental impact. Smart automation is becoming a necessity. It allows for better quality control and consistent outputs. Yet, the transition to automated systems can be daunting for some businesses. Training staff to handle new technology is essential but often overlooked.

As competition increases, businesses must adapt. The quest for efficiency drives innovation. While automatic equipment offers great potential, it raises questions. How fast can companies integrate new technology? What happens to existing jobs? These are crucial issues for the industry. Balancing progress and tradition is complex and requires thoughtful strategies.

The automatic viscose production machinery in 2026 is evolving rapidly. High efficiency is a priority. Recent industry reports indicate that automation can boost production rates by 30%. This shift is essential, given the rising demand for sustainable textiles. Machines are now equipped with advanced control systems. These systems optimize the use of raw materials, reducing waste significantly.

Several features stand out in this new machinery. For instance, real-time monitoring improves maintenance schedules. A study shows that predictive maintenance can cut downtime by up to 25%. Moreover, energy efficiency is a growing focus. Companies report a reduction in energy consumption by 15% compared to older models. Despite these advancements, some challenges remain. Adjusting to new technologies requires training and investment. Not all facilities have the budget for these upgrades.

Industry data suggests that while efficiency rises, quality control is vital. Automated processes can introduce variability. Manufacturers need to ensure consistency in the viscose they produce. Quality assurance methods are evolving too. Integrating AI into quality checks is becoming common. However, the implementation isn't flawless. Balancing efficiency with quality control can be tricky.

The automatic viscose equipment industry is evolving rapidly. Various top brands are driving innovations. These tools enhance efficiency and streamline production. Manufacturers are embracing automation to reduce labor costs. However, some challenges persist.

One common issue is maintenance. Even the best equipment requires regular check-ups. Neglecting maintenance can lead to breakdowns and production delays. Operators must stay vigilant about equipment health.

Here are some tips for choosing the right equipment. Always assess production needs. Each factory's requirement varies. Look for features that enhance flexibility. It’s crucial to invest in training for operators. Knowledge is power, especially in high-tech environments.

When evaluating the efficiency metrics of automatic viscose equipment in 2026, it becomes clear that production data offers significant insights. Each machine's performance should be measured by speed, output quality, and downtime. In this competitive landscape, understanding these aspects is crucial for success.

Tips: Monitor daily production closely. Minor adjustments can lead to big improvements. Regular maintenance cannot be overlooked. Machines that are well-maintained consistently outperform neglected ones.

Despite advancements, challenges remain. For instance, some machines struggle with consistent viscosity levels. This inconsistency affects the final product quality. It's vital to address these gaps to enhance overall efficiency. Workers often encounter unexpected breakdowns, which can derail production schedules. Finding solutions requires constant reflection and adjustment.

Tips: Encourage open feedback from operators. They often see issues before data highlights them. Incorporate a flexible schedule to accommodate unplanned downtimes. Adjusting expectations can lead to a better productivity environment.

| Equipment Model | Production Capacity (kg/h) | Energy Efficiency (kWh/kg) | Automation Level (%) | Maintenance Frequency (months) | Overall Efficiency (%) |

|---|---|---|---|---|---|

| Model A | 1200 | 0.75 | 95 | 6 | 90 |

| Model B | 1500 | 0.65 | 97 | 8 | 92 |

| Model C | 1000 | 0.80 | 90 | 5 | 88 |

| Model D | 1800 | 0.70 | 99 | 7 | 95 |

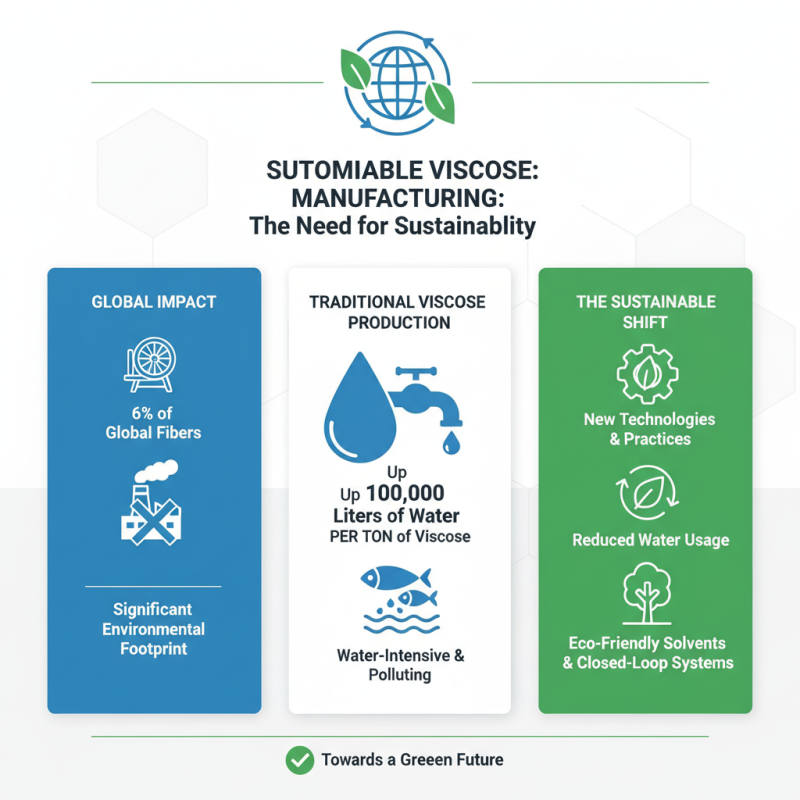

Sustainability practices in automatic viscose manufacturing are crucial for the industry. Viscose accounts for about 6% of global fibers, and its production has significant environmental impacts. Reports indicate that traditional methods are often water-intensive, utilizing up to 100,000 liters for a ton of viscose. This is a concerning figure, pushing manufacturers to seek alternatives.

New techniques focus on closed-loop systems. These systems reduce water and chemical waste significantly. Some advancements recycle up to 90% of solvents. The American Forest and Paper Association notes that reducing water usage by even 25% can save millions annually. Yet, achieving true sustainability remains challenging.

Innovative practices need ongoing evaluation. Many manufacturers still rely on outdated processes. The industry struggles with the balance between efficiency and environmental responsibility. Comprehensive reports suggest that improving training for workers on best practices could enhance sustainability efforts. The path to a more sustainable viscose industry is complex and requires continuous, genuine reflection on current methods.