Leave Your Message

Choosing the right Automatic Spunlace Line can significantly impact your production efficiency. Industry expert Dr. Jane Smith stated, "The right equipment can uplift your business performance." This emphasizes the importance of making informed decisions when selecting machinery.

Automatic Spunlace Lines vary greatly in features and specifications. Each brand offers unique benefits, making your choice pivotal. Consider factors like production capacity, automation level, and maintenance requirements. Some lines may look advanced but could have hidden drawbacks.

Visualize your production process. Imagine the smooth operation of a well-chosen Automatic Spunlace Line. It should fit seamlessly into your workflow, yet finding the perfect match may cause some confusion. Reflect on your specific needs and long-term goals. Each decision shapes your operational landscape.

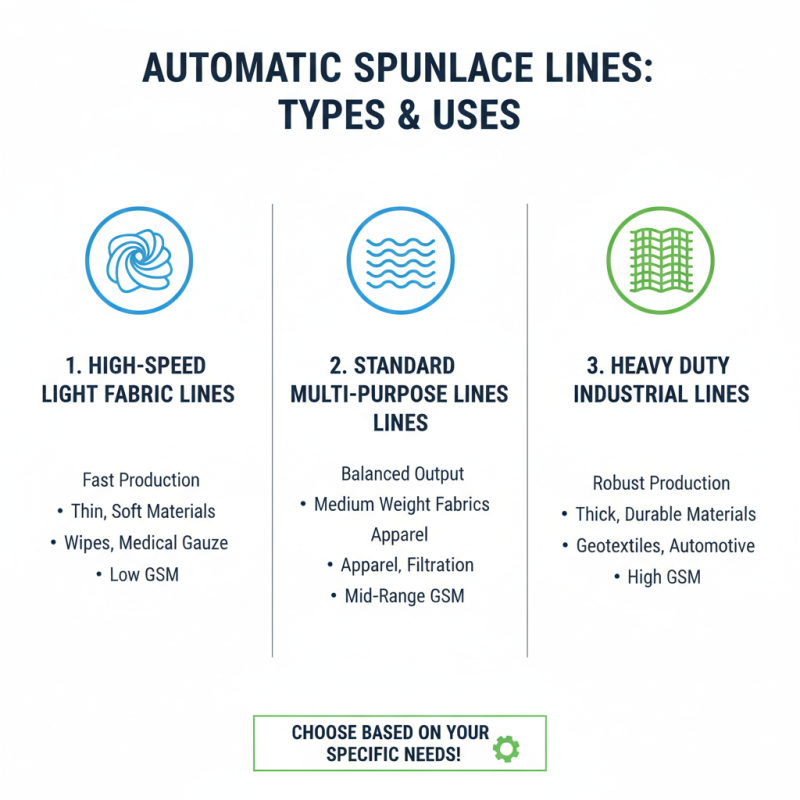

When selecting an automatic spunlace line, it’s crucial to understand the various types available. Each type serves unique functions. These machines vary in speed, output, and end-product quality. Some models excel at producing lighter fabrics, while others are best for heavier materials. This makes a huge difference depending on your specific needs.

Different automatic spunlace lines utilize various technologies. For instance, some employ high-pressure water jets for better fiber entanglement. Others might focus on energy efficiency or user-friendly interfaces. You’ll also find models that offer versatility in fabric thickness. This feature is valuable if your production demands change.

Many manufacturers promise ease of maintenance. Yet, some lines could be harder to maintain than expected. Parts might wear quicker or malfunctions might occur. It’s important to weigh the pros and cons carefully. Researching machine specifications and reading reviews can offer insights, but remember, firsthand experience is irreplaceable.

Choosing the right automatic spunlace line can be challenging. Key features must be thoroughly evaluated. Pay attention to production capacity, efficiency, and raw material compatibility. A typical spunlace line can achieve an output of up to 6,000 tons per year, which significantly impacts operational efficiency.

Consider the technology used in the equipment. Advanced technology can improve the quality and consistency of the spunlace products. According to industry reports, lines equipped with real-time monitoring systems reduce downtime by approximately 15%. Such features enhance overall productivity but may require higher initial investment.

Another crucial aspect is the ease of maintenance. Equipment that is difficult to maintain can lead to production delays. Some reports indicate that poorly maintained lines can decrease output by 20%. Ensure that the design allows for easy access. This can save time and money in the long run. Balancing advanced features with practicality is vital for the long-term success of your production line.

When selecting an automatic spunlace line, assessing production capacity is crucial. Production capacity directly impacts manufacturing output and efficiency. According to industry reports, modern spunlace lines can produce over 15 tons of non-woven fabric per day. However, this number varies based on machine settings, material types, and operator skill levels.

Efficiency is another factor to consider. A highly efficient line operates with minimal downtime. For instance, cutting downtime by just 10% can increase overall productivity by 5-7%. Additionally, the integration of automation can lead to a more streamlined process. Automated systems can adjust speed and pressure, resulting in better quality fabrics. Yet, the reliance on technology also creates dependencies on technical support and equipment reliability.

Moreover, it’s essential to reflect on the long-term maintenance of the equipment. The costs can escalate if spare parts are not readily available. Understanding the local market for these components can save time and money. Balancing capacity, efficiency, and maintenance will ensure your spunlace line meets production needs effectively.

When selecting an automatic spunlace line, pricing trends are crucial. Industry reports indicate that the price range for these lines can vary significantly. For example, a basic model may cost around $150,000, while high-end versions might exceed $500,000. This vast difference highlights the need for careful consideration.

Cost considerations extend beyond the purchase price. Maintenance costs can add up. Some spunlace lines require specialized parts that are expensive to replace. A recent study showed that maintenance accounted for nearly 20% of total ownership costs over five years. This should influence your decision-making.

Operational efficiency is another factor to weigh. Automated lines can enhance productivity, yet they might have higher initial costs. Many manufacturers report challenges in training staff on new technology. These aspects can lead to unanticipated expenses. Always assess your current and future needs. An informed decision today can save significant costs tomorrow.

When considering an automatic spunlace line, after-sales support and maintenance services are crucial. These services ensure your equipment runs smoothly post-purchase. A 2023 industry report indicates that 75% of equipment failures stem from improper maintenance. Regular servicing can extend equipment life and improve performance. It's essential to have a reliable support system to minimize downtime.

Tip: Always ask potential suppliers about their maintenance offerings. Understand their response times and availability of spare parts. A quick response can save you from costly production delays. A company providing comprehensive after-sales support could be more beneficial in the long run.

Moreover, consider the level of training offered for your staff. Operators need to manage complex machinery confidently. A lack of proper training can lead to mistakes, causing inefficiencies. Some reports suggest that well-trained staff can boost productivity by over 20%. Investing in training may seem expensive, but the returns often justify the initial costs. Evaluate the training programs before making your decision; it’s a long-term investment.

| Criteria | Importance Level (1-5) | Key Features to Consider | After-Sales Support | Maintenance Services |

|---|---|---|---|---|

| Production Capacity | 5 | Output speed, volume output | 24/7 technical support | Scheduled maintenance availability |

| Energy Efficiency | 4 | Power consumption, eco-friendly features | Energy audits | Energy optimization services |

| Technology Compatibility | 5 | Integration with existing systems | Software updates | Technical training sessions |

| Quality of Output | 5 | Consistency, durability of products | Quality assurance support | Regular check-ups |

| Cost of Ownership | 4 | Initial cost, operational costs | Transparent pricing plans | Cost-effective maintenance contracts |