Leave Your Message

Selecting the right equipment is critical for any textile business. One key investment is the "Textile Fabric Machine." These machines enable manufacturers to produce high-quality fabric efficiently. A well-functioning machine can streamline operations and enhance productivity.

However, not all machines are created equal. Choosing the right type of Textile Fabric Machine can be challenging. It's important to evaluate specifications, capabilities, and your specific needs. Sometimes, businesses make impulsive choices and later regret them. Investing time in research can save money in the long run.

Moreover, understanding the maintenance and support required for these machines is vital. A machine that breaks down frequently can disrupt production. Hence, assessing the reliability and customer service of suppliers is essential. In the end, making the right choice can lead to improved efficiency and profitability in your textile operations.

Investing in textile fabric machines can greatly enhance operational efficiency. Reports indicate that the global textile machinery market is expected to grow at a CAGR of 5.4% from 2022 to 2030. Such growth is largely propelled by rising automation demands and operational cost reductions. Businesses that adopt state-of-the-art machinery often see a significant decrease in production time. This translates to quicker turnaround for customer orders.

Additionally, modern machines offer precision and adaptability. They can handle diverse fabrics and designs. According to industry surveys, companies using automated textile machines report a 30% increase in production accuracy. However, it is crucial to consider the initial investment costs. Not all businesses may be ready to make a significant financial leap. Evaluating ROI is essential before a large purchase.

Investments in textile machinery also pave the way for sustainable practices. Many machines are designed to minimize waste and energy consumption. A recent analysis found that 20% of textile production waste can be reduced with efficient machines. Yet, businesses must remain vigilant. Not maintaining these machines can lead to higher operational costs and diminished returns. Balancing technology and maintenance is key for long-term success.

When choosing textile fabric machines, certain features are essential. Efficiency is a key factor. Machines that can operate at higher speeds can boost productivity. According to an industry report by Technavio, the textile machinery market is expected to grow by over 3% annually until 2025. This growth highlights the rising demand for efficient machines in production lines.

Durability is another feature worth considering. Machines made with high-quality materials can withstand heavy use and last longer. A detailed study from Research and Markets indicates that durable machines reduce maintenance costs by 15% over five years. This savings can significantly impact a business's bottom line.

Flexibility in fabric types is also crucial. Machines that can handle multiple materials provide versatility. However, adaptability comes with a trade-off. Not all machines perform equally across different fabrics. Some businesses find themselves needing multiple machines for various tasks, which can lead to increased expenses. Balancing these factors is vital for business owners.

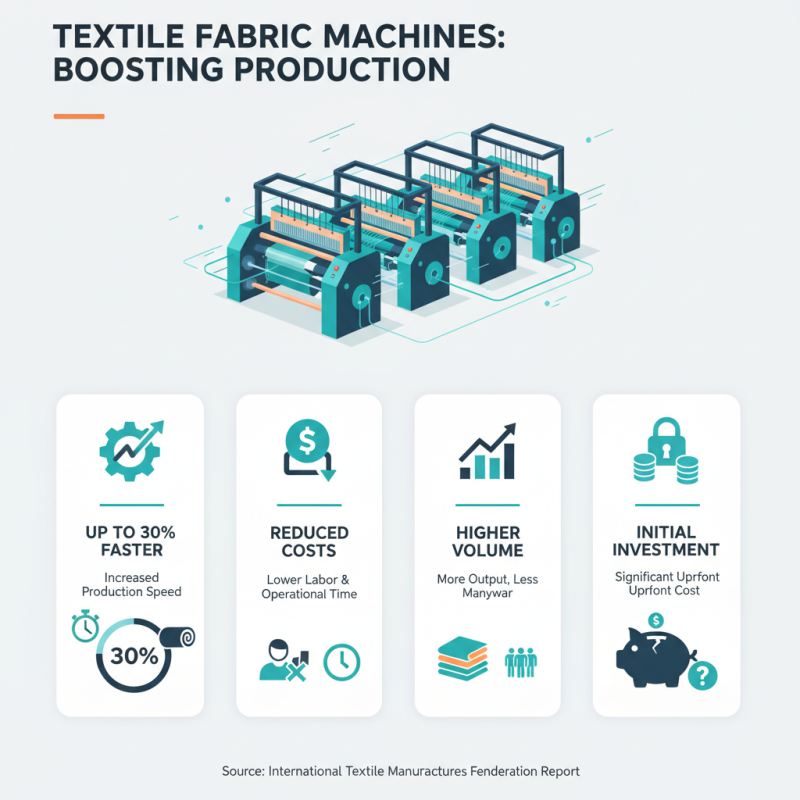

Textile fabric machines are pivotal in boosting production efficiency within the industry. A recent report by the International Textile Manufacturers Federation indicates that automated textile machines can increase production speeds by up to 30%. This enhancement often translates to lower labor costs and reduced operational time. Companies that integrate these machines can expect to produce higher volumes with less manpower. However, the initial investment can be a hurdle for many businesses.

Moreover, precision in fabric production is crucial. Advanced fabric machines enable manufacturers to achieve tighter tolerances, minimizing waste. The Fabric Manufacturers Association highlights that reducing fabric waste by just 5% can result in significant cost savings annually. Yet, some may overlook the importance of regular maintenance, which can lead to breakdowns and inefficiencies.

The transition to automated textile machines also brings challenges. Training workers to operate complex machinery is essential. A study from the Textile Research Journal suggests that companies often underestimate the learning curve involved. Failure to address this can lead to inconsistent quality and production delays. Businesses must weigh the benefits against these obstacles to improve their production efficiency effectively.

When it comes to business growth, investing in textile fabric machines can be a game changer. The global textile industry is projected to reach a value of over $1 trillion by 2025. This growth creates opportunities for businesses to innovate and scale. Cost-effectiveness is a significant aspect that cannot be overlooked. High-quality textile machines can reduce labor costs by automating tedious processes. This means better productivity and fewer mistakes.

*Tip: Research current market trends. Understanding demand can guide your purchase decisions for textile machines.*

Initial investments can seem daunting. However, the return on investment is often substantial. Many businesses report reducing production costs by up to 30% thanks to improved efficiencies. Ignoring new technology can put companies at a disadvantage. Innovative machines not only save money but also allow for a wider product range. This can attract new customers and enhance loyalty.

*Tip: Evaluate machine performance. Regular maintenance ensures longevity and efficiency.*

Implementing state-of-the-art fabric machines may expose weaknesses in current operations. Reflect on your existing processes to identify gaps. Are you maximizing your machine's capabilities? Continuous improvement is key to staying competitive in this dynamic market.

| Aspect | Details | Cost Impact | Estimated Savings |

|---|---|---|---|

| Operational Efficiency | Automated processes reduce labor costs. | Lower operational costs by 30%. | Up to $50,000 annually. |

| Quality Improvement | Higher precision and consistency in fabric production. | Reduces material waste by 15%. | Around $30,000 yearly. |

| Market Competitiveness | Ability to produce diverse and high-quality products. | Increased customer satisfaction and retention. | Potentially $20,000 additional revenue. |

| Energy Efficiency | Modern machines consume less energy. | 10% reduction in energy costs. | Estimated at $10,000 per year. |

| Return on Investment | Short payback period for machinery costs. | ROI in less than 2 years. | Overall increase in profitability. |

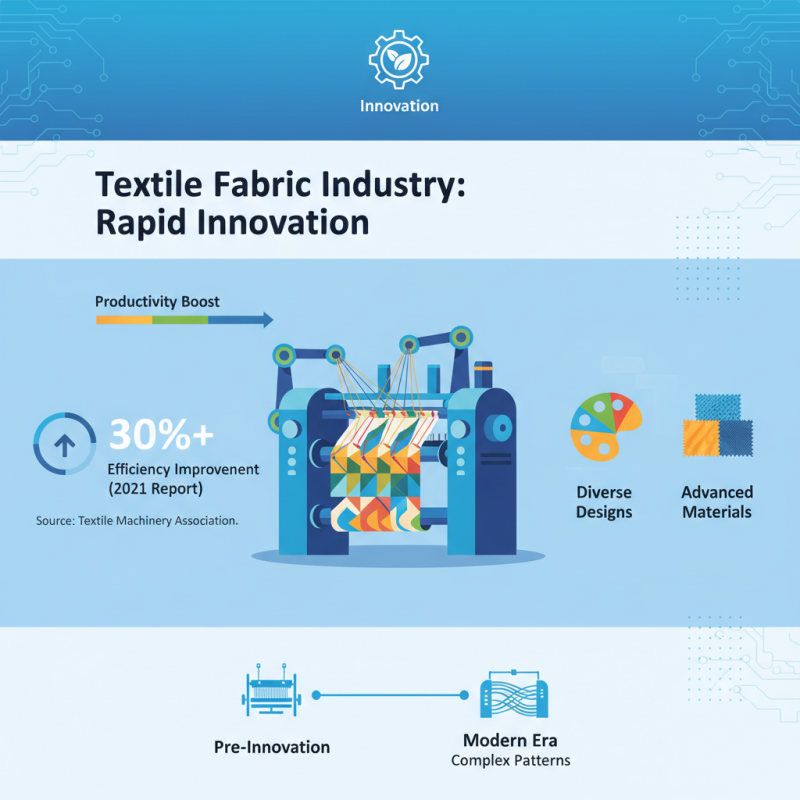

The textile fabric industry is undergoing rapid innovation. Advanced textile fabric machines significantly enhance productivity. In 2021, automated technologies improved efficiency by over 30%, according to a recent report by the Textile Machinery Association. This shift is not only about speed; it also brings diversity in designs and materials. The latest machines can produce complex patterns that were once impossible.

Sustainability is another key factor. Many modern machines use eco-friendly processes. Reports indicate that around 70% of companies are adopting such technologies. This shift reduces waste and energy consumption. However, implementing these innovations requires significant investment. Companies need to evaluate whether the ROI justifies the costs. There's a risk involved, especially for smaller businesses.

Moreover, the learning curve for operating advanced machines can be steep. Workers may require extensive training. This transition may create short-term disruptions. Such challenges are important to acknowledge as businesses navigate the evolving landscape. Innovation in textile fabric machine technology is not without its obstacles. However, its potential benefits offer a compelling case for many businesses to explore this path.