Leave Your Message

In the rapidly evolving landscape of 3D printing, the choice of Automatic Filament Equipment can significantly impact both the quality and efficiency of the printing process. As highlighted in a recent industry report by Smithers Pira, the market for 3D printing technologies is projected to reach USD 44.5 billion by 2025, indicating a surging demand for robust and innovative equipment. Implementing the right automatic filament system not only streamlines production but also enhances material utilization, which is crucial in an industry striving for sustainability.

According to Dr. Jane Thompson, a leading expert in additive manufacturing, "Selecting the appropriate Automatic Filament Equipment is essential for achieving optimal results in 3D printing." Her insights emphasize the critical nature of this choice, as the right equipment can facilitate the seamless integration of multiple filament types and support diverse manufacturing applications. As companies increasingly seek to advance their manufacturing capabilities, understanding the key features and benefits of automatic filament systems has become more important than ever. An informed decision can lead to better print quality, reduced operational costs, and a stronger competitive edge in the dynamic 3D printing market.

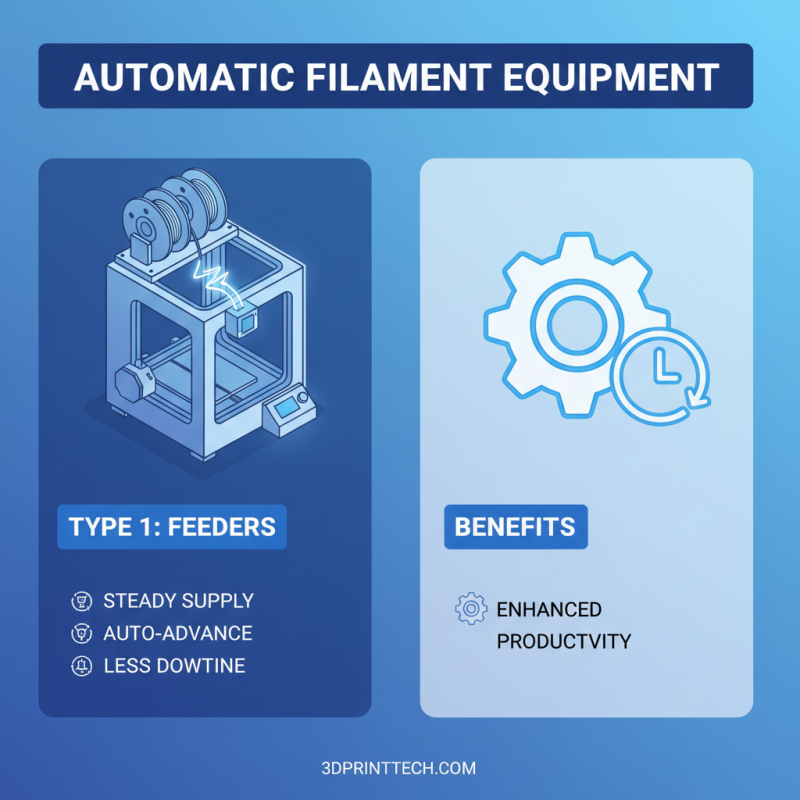

When selecting automatic filament equipment for your 3D printing needs, it's essential to understand the various types available. First, we have automatic filament feeders, which are designed to streamline the printing process by ensuring a steady and consistent supply of filament to the printer. These feeders can detect when filament is running low and automatically advance new material, preventing interruptions during lengthy prints. This type of equipment is particularly useful for large projects, as it minimizes downtime and enhances productivity.

Another notable category is automatic filament spoolers. These devices help manage and organize spools of filament, often integrating features such as temperature control and humidity monitoring to maintain the integrity of the filament. An effective spooler will not only extend the life of your materials but also facilitate easier loading and changeover between different filament types. Depending on your printing volume and preferences, selecting the right spooler can significantly impact both the quality and efficiency of your projects.

Lastly, consider the role of filament drying systems. High-quality printing requires materials that are free from moisture, as this can cause defects during the printing process. Automatic filament dryers work by providing a controlled environment that keeps filament at optimal temperatures and humidity levels, ensuring consistent results for each print. Understanding these types of automatic filament equipment will guide you in making an informed decision tailored to your specific printing requirements.

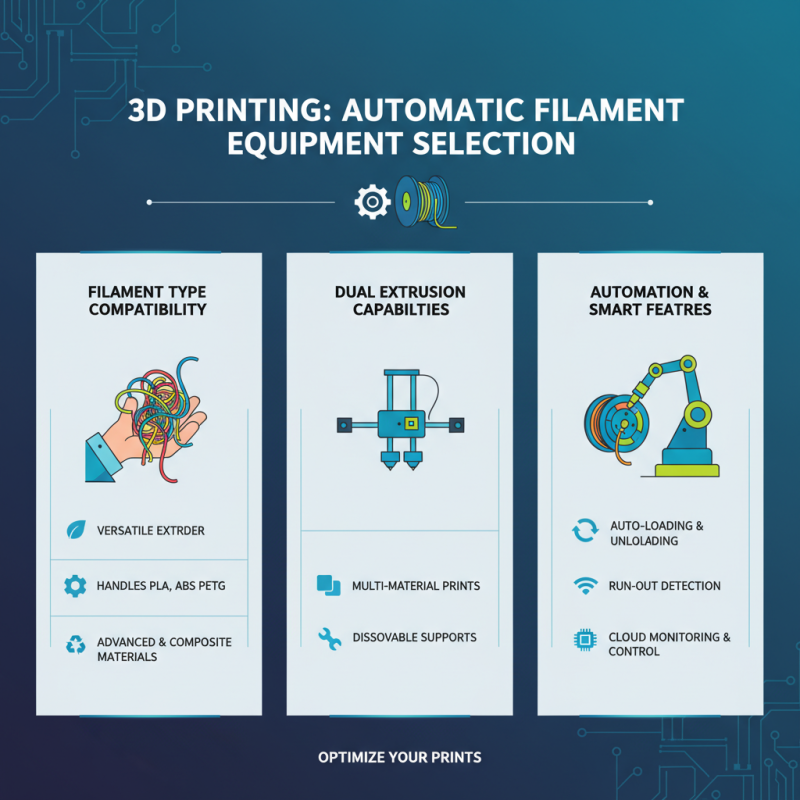

When selecting automatic filament equipment for 3D printing, several critical features should be prioritized to ensure optimal performance and compatibility with your printing needs. First, consider the type of filament the equipment can handle. Different 3D printing projects require various materials such as PLA, ABS, or PETG, and not all machines cater to every type. Ensure the equipment you choose has a versatile extruder and hotend capable of managing the specific filaments you plan to use, especially if you intend to experiment with advanced or composite materials.

Another important feature to evaluate is the machine's ease of use and calibration. Reliable automatic filament equipment should simplify the setup process and minimize the need for constant manual adjustments. Look for features like auto-bed leveling, user-friendly interfaces, and intuitive software that can help streamline your workflow. Additionally, pay attention to the build quality and stability of the equipment since these aspects significantly influence print quality and consistency. A robust frame and well-engineered components can reduce vibration and wobbling, leading to more precise printing results.

When choosing automatic filament equipment for your 3D printing projects, evaluating compatibility with your specific 3D printer model is crucial. Each printer comes with its own set of specifications, including filament diameter, feed mechanism, and temperature requirements. It is essential to thoroughly review your printer's manual or manufacturer guidelines to ensure that the filament equipment you consider can handle these factors effectively. Mismatches in filament type or size can lead to poor print quality or even damage to your printer.

In addition to size compatibility, it’s vital to assess how the automatic filament system integrates with your printer’s software and hardware. Some systems may require specific settings or firmware updates to function correctly, which could complicate the setup process. It’s also beneficial to look for features like filament sensing and automatic feeding mechanisms that align with your printer's existing capabilities. By ensuring that the automatic filament equipment is designed to work seamlessly with your printer, you'll enhance reliability and streamline your 3D printing workflow.

This bar chart illustrates the compatibility ratings of various filament types with 3D printers. Each filament type is rated on a scale from 1 to 10 based on general compatibility with most 3D printer models.

When selecting automatic filament equipment for 3D printing, the quality and reliability of filament supplies are critical factors that can significantly impact the printing process and final output. High-quality filament not only ensures better adhesion and layer bonding but also minimizes issues such as clogging and inconsistent extrusion. To thoroughly assess filament quality, it's essential to examine the material composition, diameter consistency, and the presence of additives that might enhance properties such as strength, flexibility, or heat resistance. Filament that adheres to industry standards and provides proper certifications can often guarantee a level of reliability that is crucial for seamless printing.

Another important aspect to consider is the reputation and track record of filament suppliers. Evaluating user reviews and feedback can provide insights into the reliability of different materials over time and under various printing conditions. It's also beneficial to investigate whether suppliers have established quality assurance measures in place, such as regular testing and batch tracking. Engaging with a community of 3D printing enthusiasts can reveal firsthand experiences with various filament suppliers, helping you to make more informed decisions. By focusing on these factors, you can ensure that the filament supplies you choose will support not only your specific printing requirements but also enhance the overall reliability of your 3D printing endeavors.

When choosing automatic filament equipment for 3D printing, budget considerations are crucial to ensure a balanced approach between cost and performance. It's essential to evaluate the specific needs of your projects, as higher cost does not always equate to superior performance. For example, while pricier models may offer advanced features such as faster processing speeds or automated material handling, these benefits may not be necessary for every user. Identifying the primary functions you require can help in narrowing down the options.

Additionally, it’s important to understand the potential long-term savings that come from investing in higher-quality equipment. Cheaper options might save you money upfront but could lead to increased maintenance costs and lower reliability over time. Balancing initial investment with durability and efficiency can significantly affect your overall costs. By conducting thorough research and weighing performance against price, you can make a more informed decision that meets both your budget and your 3D printing requirements effectively.