Leave Your Message

In the world of textile production, selecting the right Automatic Lyocell Equipment can be a challenging task. Industry expert Dr. Emily Carter once stated, "The right machinery can make or break your production efficiency." This insight emphasizes the importance of careful selection in achieving optimal results.

When choosing Automatic Lyocell Equipment, consider various factors. Evaluate the machine's efficiency, durability, and ease of use. Look for features that enhance the production process. An ideal machine should streamline workflows and reduce waste.

However, the decision-making process can be overwhelming. With so many options available, one may feel lost. It's essential to reflect on specific production needs and budget constraints. Finding the perfect fit may take time and research, but the investment pays off in quality and efficiency.

Choosing the right automatic lyocell equipment can significantly enhance the production process. Lyocell, known for its sustainability, requires precise machinery. Understanding how these machines work is crucial for efficiency. Automatic equipment usually includes spinning, washing, and drying systems.

The spinning phase is essential. It transforms cellulose into fibers. A good spinning machine must have adjustable settings. This allows for more control over fiber quality. Inadequate settings can lead to uneven fibers, which can affect the final product.

When considering washing machines, focus on water usage. High efficiency is key here. Automatic systems should minimize water while ensuring cleanliness. Excess water usage can lead to high operational costs.

Tips: Always read user reviews before making a purchase. Inspect maintenance requirements of the equipment. Look for machines that offer easy troubleshooting options. Mistakes in choice could lead to wasted resources and time. Rethinking your approach may lead to better outcomes in lyocell production.

When selecting automatic lyocell equipment, it's crucial to consider a few key features. Firstly, look for equipment with efficient energy consumption. Energy costs can significantly impact production. An efficient machine can save money and reduce environmental impact. Additionally, assess the ease of operation. User-friendly features can streamline the process, minimizing training time and errors during production.

Next, focus on the equipment's scalability. As production demands change, your machinery should adapt. Choose models that can handle varying capacities without significant modifications. Consider the maintenance requirements too. Machines with complicated upkeep can lead to downtime. Frequent maintenance can disrupt production schedules and increase costs.

Lastly, check for automation levels. High automation can enhance precision and reduce labor needs. However, too much automation may lead to loss of control over the process. Balancing automation with operator oversight is essential. Finding the right equipment is about adapting to specific production needs, and sometimes it’s a trial-and-error journey.

| Feature | Description | Importance | Example Value |

|---|---|---|---|

| Automation Level | Degree of automation in the process including material handling, fiber production, and quality control. | High | Fully automated |

| Energy Efficiency | Efficiency of equipment in terms of power consumption during operation. | High | <50 kWh per ton |

| Production Capacity | Max fiber output that the equipment can handle, usually measured in tons per day. | Medium | 20 tons/day |

| Control Systems | Integration of advanced control systems for real-time monitoring and adjustments. | High | IoT-enabled |

| Maintenance Requirements | Frequency and complexity of maintenance activities needed to keep equipment running. | Medium | Monthly check-ups |

| Environmental Impact | The ecological footprint of the equipment, including waste management and emissions. | High | Low emissions |

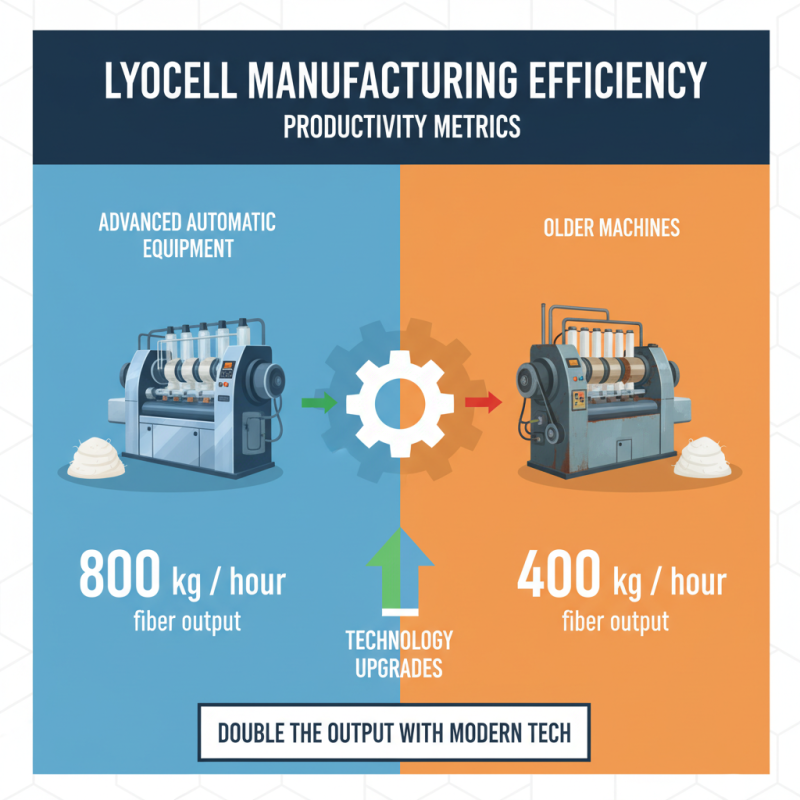

When assessing efficiency in Lyocell manufacturing, productivity metrics play a crucial role. It's essential to evaluate machine throughput. This refers to the amount of fiber produced per hour. Industry reports indicate that advanced automatic Lyocell equipment can achieve up to 800 kg of output every hour. However, older machines may only reach 400 kg. This discrepancy highlights the importance of technology upgrades.

Additionally, energy consumption must be considered. Modern Lyocell processes are designed to minimize energy usage. Reports show that newer systems consume up to 30% less energy than their predecessors. This significant reduction can lead to cost savings over time. However, it's essential to weigh these savings against initial investment costs. A careful cost-benefit analysis is necessary before making decisions.

Moreover, the sustainability of the production process is becoming increasingly important. Research indicates that improving equipment efficiency directly correlates with reduced water usage. Efficient machines can save up to 50% more water than older models. Yet, industries must reflect on the methods used to maintain these efficiencies. Regular maintenance, operator training, and process adjustments are critical for sustaining high productivity levels. Emphasizing these elements can lead to more effective Lyocell manufacturing overall.

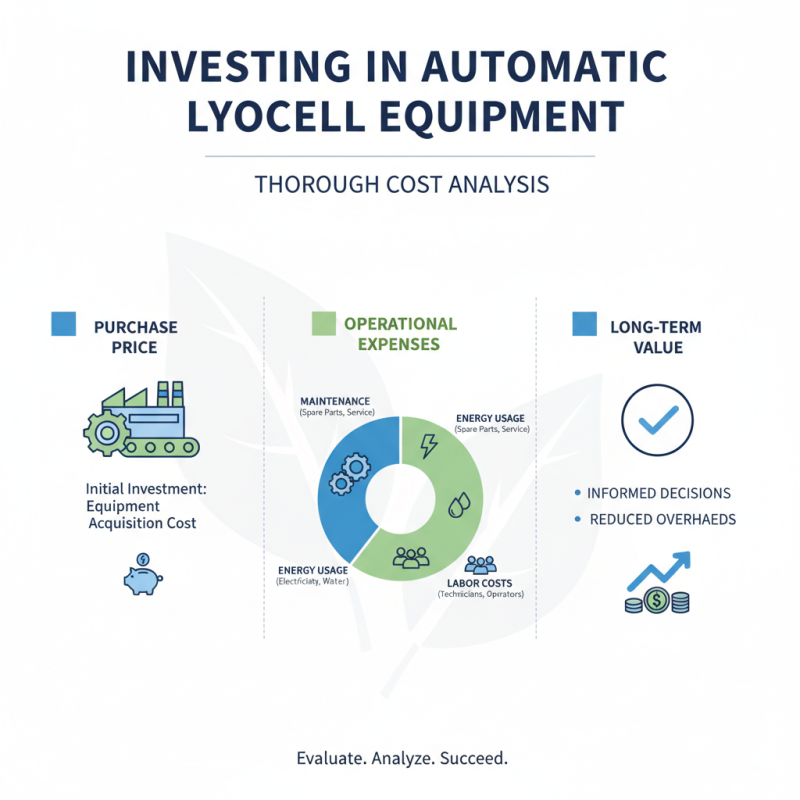

Investing in automatic Lyocell equipment involves thorough cost analysis. It's essential to evaluate not just the purchase price but also long-term operational expenses. These include maintenance, energy usage, and labor costs associated with running the equipment. A detailed breakdown of these costs helps in making informed decisions.

Budgeting for such investments can be challenging. Many companies underestimate hidden costs. For instance, installation and training may require additional funds. unexpected repairs could lead to financial strain. Before committing, create a realistic budget that includes potential contingencies and explore financing options. This can provide breathing room in critical times.

When assessing value, consider production efficiency as well. High-quality equipment may have a higher initial price but could save money over time. Calculate the return on investment based on increased productivity. It's vital to balance higher costs with the potential for greater output. This reflection can significantly impact your decision-making process.

In recent years, lyocell has gained popularity as a sustainable fabric choice. This is due to its environmental benefits during production. The process utilizes wood pulp from sustainably managed forests. However, many still overlook the ecological impact of automatic lyocell equipment. Choices made today will influence the industry tomorrow.

When selecting equipment, consider its energy consumption. Look for machines that optimize power use. This reduces overall emissions. Efficient machinery can also decrease water usage. Remember, every drop counts. Implementing water recycling systems in production can significantly lessen waste.

Tips: Always review the lifecycle of equipment. Think about how long it will last. An investment in durable machinery pays off over time. Also, prioritize suppliers who adhere to sustainable practices. Ask about their sourcing and waste management. This ensures your production aligns with eco-friendly values. Reflect on the balance between production speed and sustainability. Fast isn't always better, especially in this industry.