Leave Your Message

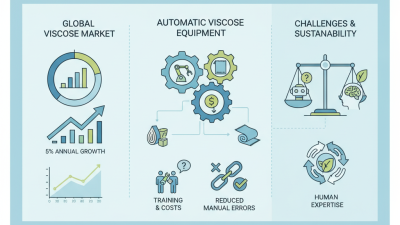

Choosing the right Automatic Viscose Equipment can shape the future of your textile production. The viscosity control, spinning technology, and eco-friendliness of these machines are vital. Your choice will affect quality, cost, and efficiency.

Understanding your production needs is crucial. What type of viscose will you produce? The equipment should match your volume and desired specifications. Sometimes, manufacturers provide complex systems that may confuse operators.

Additionally, consider maintenance and support. User-friendly machinery will reduce downtime. It’s important to reflect on the long-term costs. Cheaper equipment may lead to higher repairs. Sometimes, investing in quality pays off in efficiency. A good balance is key.

Viscose production is a complex process that requires specific equipment. Understanding the key equipment types is crucial for manufacturers. The process begins with cellulose extraction from natural sources, primarily wood pulp. This cellulose is then dissolved in sodium hydroxide to form alkali cellulose. Knowledge of these initial steps can help in selecting the right equipment.

For viscose production, key machinery includes dissolving tanks and spinnerets. Dissolving tanks must maintain precise temperature and pressure. Data shows that effective temperature control can improve yield by up to 25%. Spinnerets are critical for fiber formation. A slight variance in nozzle design can affect fiber diameter and quality.

However, not all equipment performs optimally for every plant. Factors like equipment age and maintenance can lead to inconsistencies in production. Upgrading machinery can involve substantial costs, leading to hesitation. Industry reports indicate that around 40% of manufacturers face challenges with outdated technology. Reflecting on these aspects is vital for operational efficiency.

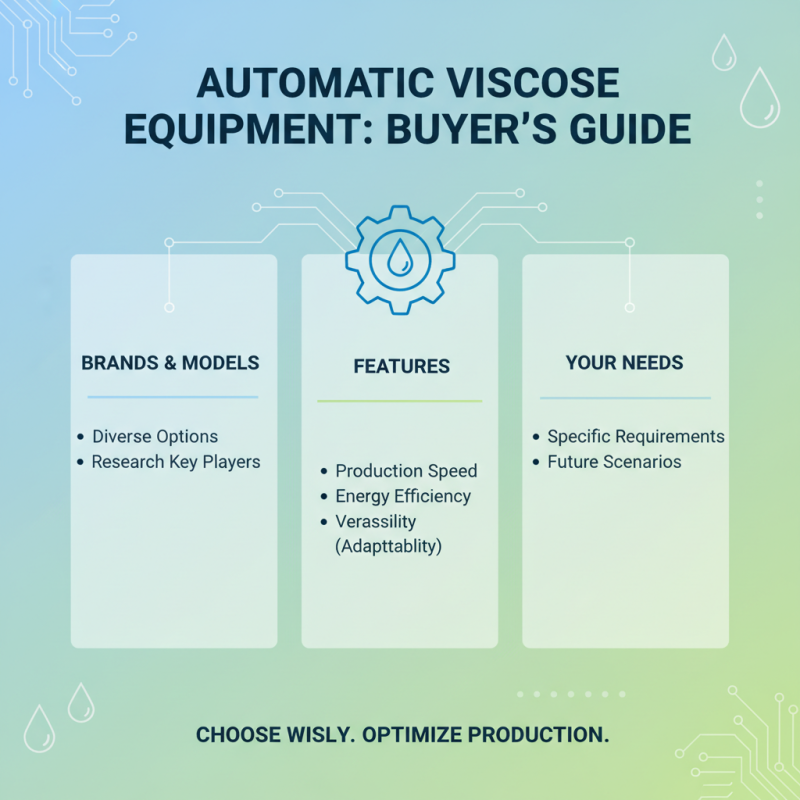

When selecting automatic viscose equipment, performance and efficiency are crucial metrics to consider. Equipment effectiveness can significantly impact production rates and quality. Look at the machine's speed and output capacity. A higher speed may seem appealing, but it should not compromise the fabric's quality. Efficiency often comes down to energy consumption. Machines that operate on lower energy levels can save costs over time, but their initial investment may be higher.

Another key aspect is the automation level of the equipment. Fully automated systems can minimize human error, ensuring consistent results. Yet, more automation often means complex maintenance. Users should be prepared for potential downtime caused by technical issues. It's vital to evaluate repair frequency and ease of access to replacement parts. Balancing innovation with practical usability is essential.

Flexibility is also important in your assessment. Adaptable machines can accommodate various yarn types and production runs. However, this versatility can sometimes lead to longer setup times. Understanding how the machine fits into your production line is critical. Analyze specific production needs before making a decision. A one-size-fits-all approach may not yield the desired results. Always consider your unique operational context when choosing equipment.

| Model | Production Capacity (kg/h) | Energy Consumption (kW) | Efficiency (%) | Features |

|---|---|---|---|---|

| Model A | 500 | 120 | 90 | Automated process, low maintenance |

| Model B | 600 | 110 | 92 | High precision control, energy saving |

| Model C | 550 | 115 | 88 | Compact design, user-friendly interface |

| Model D | 700 | 130 | 95 | Advanced automation, high throughput |

When exploring automatic viscose equipment, understanding the available brands and models is essential. The market has diverse options, each with unique features. Some may excel in production speed, while others focus on energy efficiency. It is vital to consider your specific needs. Some equipment may lack versatility. This could hinder adaptability in different production scenarios.

Many leading brands offer advanced technology, yet not all models are user-friendly. Operators may face difficulties with complicated controls. Simple interfaces can enhance efficiency, making operation smoother. Reviews and user experiences can provide valuable insights. Equipment should not only meet technical specifications but also add value through ease of use.

Budget constraints also play a significant role in decision-making. Higher prices do not always guarantee the best performance. Analyzing cost-effectiveness is crucial. Some brands might have hidden costs for maintenance and parts. Exploring these factors can lead to better-informed decisions. The ideal solution combines functionality, reliability, and affordability. It’s worth reflecting on what truly matters for your production goals.

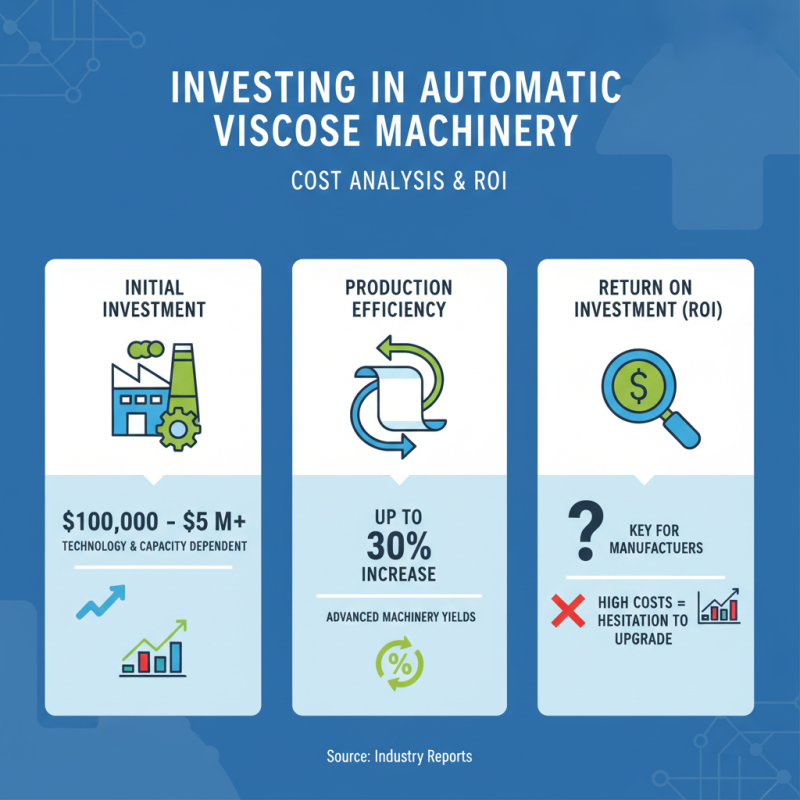

When investing in automatic viscose machinery, cost analysis plays a crucial role. According to industry reports, the initial investment can range from $100,000 to over $1 million, depending on the technology and capacity. For many manufacturers, understanding the return on investment (ROI) is key. The projection shows that advanced machinery can yield up to a 30% increase in production efficiency. However, many companies still hesitate to upgrade due to high costs.

Operating expenses should also be considered. Energy consumption is a significant factor. Automatic machines can consume 20-30% less energy than manual systems. Nevertheless, the upfront cost may be intimidating. Maintenance costs pose another challenge. On average, maintenance can account for 5-10% of overall operational expenses. Identifying reliable suppliers and assessing their support can mitigate long-term costs.

Balancing investment against potential output requires careful planning. Some manufacturers prioritize machinery that promises high efficiency but may overlook the impact of fluctuating market demands. It's vital to reflect on scalability and adaptability, especially with evolving technology. Evaluating these factors can lead to more informed decisions for future growth in the viscose industry.

The future of automatic viscose equipment is shaping up around two key ideas: innovation and sustainability. As technology advances, manufacturers are focusing on more efficient processes. These innovations are expected to enhance productivity and reduce waste, making production cleaner. For instance, incorporating smart sensors can optimize resource usage, helping to conserve valuable materials and energy.

Tips: Consider energy-efficient models. They may save costs in the long run. Research emerging technologies that could enhance your production line.

Sustainability is no longer just a trend; it's a necessity. The viscose industry faces pressure to decrease its environmental impact. This push leads to the development of biodegradable materials and closed-loop systems. Such systems recycle chemicals, significantly lowering emissions. However, challenges remain. Adopting these innovations often comes with a steep learning curve.

Tips: Stay updated on industry reports. Joining networks can provide insights into the latest sustainable practices. Engage with peers to share experiences.