Leave Your Message

In the dynamic landscape of the textile industry, the choice of machinery plays a pivotal role in determining the efficiency and quality of production. Among the various types of machines available, the Ring Spinning Machine has emerged as a popular choice for businesses aiming to enhance their yarn production capabilities. As we approach 2025, it becomes increasingly essential for textile manufacturers to make informed decisions regarding their equipment investments. This involves not only understanding the functionalities and advantages of Ring Spinning Machines but also evaluating their compatibility with the specific requirements of one’s production processes.

The decision-making process for selecting the ideal Ring Spinning Machine involves several critical factors, including technology advancements, operational efficiency, and adaptability to varying yarn types. With continuous technological progress, 2025 presents a unique opportunity for textile businesses to leverage improved features that can optimize their workflow and reduce costs. Additionally, the rising demand for sustainable practices within the industry urges manufacturers to consider machines that promote eco-friendly production methods. As such, this guide will delve into key considerations and strategies for choosing a Ring Spinning Machine that aligns with your business goals, setting the stage for a successful and sustainable future in textile manufacturing.

Ring spinning machines play a crucial role in the textile production process, particularly in creating high-quality yarn that is essential for various fabrics. According to a report by Mordor Intelligence, the global ring spinning machine market was valued at approximately $3.01 billion in 2020 and is expected to grow at a CAGR of 4.5% from 2021 to 2026. This growth underscores the significance of selecting the right machinery for textile production, as advancements in technology continually improve efficiency and quality in spinning operations.

The importance of ring spinning machines lies primarily in their ability to produce finer and stronger yarn compared to other spinning methods. The International Textile Manufacturers Federation (ITMF) reported that ring-spun yarn holds about 70% of the market share in yarn production due to its superior characteristics, such as durability and softness. As textile businesses look to enhance their product offerings, understanding the attributes of different ring spinning machines—such as spindle speed, energy consumption, and automation features—becomes essential in making informed purchasing decisions. By investing in innovative ring spinning technology, manufacturers can significantly boost their operational efficiency and respond to evolving market demands.

When selecting a ring spinning machine for your textile business in 2025, several key features must be carefully evaluated to ensure optimal performance and efficiency. The ability to achieve higher yarn quality while maintaining low energy consumption is critical. Machines equipped with advanced technology such as intelligent tension control systems can significantly enhance the quality of the yarn produced, leading to better end products and satisfied customers. Furthermore, opt for machines with automation features that can streamline operations and reduce labor costs.

Another important consideration is the machine's adaptability and ease of maintenance. In an ever-evolving industry, the capability to quickly adjust settings for different yarn types or production volumes can provide a competitive edge. Machines designed with user-friendly interfaces and modular components not only ease the learning curve for new operators but also facilitate quicker repairs, minimizing downtime. Finally, evaluating energy efficiency ratings and sustainability features becomes increasingly essential, as businesses strive to meet environmental standards and reduce operational costs while maintaining a commitment to sustainable practices.

| Feature | Description | Importance Level |

|---|---|---|

| Spinning Speed | Maximum revolutions per minute (RPM) for higher production efficiency. | High |

| Fiber Compatibility | Capability to spin various fiber types, including cotton, polyester, and blends. | Medium |

| Energy Efficiency | Energy consumption rates and innovative tech for reducing power usage. | High |

| Automation Features | Integration of automation for monitoring and controlling the spinning process. | High |

| Maintenance Needs | Frequency and ease of maintenance required to ensure optimal performance. | Medium |

| User Interface | Ease of use, clarity, and accessibility of the control panel and settings. | Medium |

| Cost | Initial investment and overall cost of ownership over time. | High |

The selection of a ring spinning machine is crucial for enhancing the efficiency and output of a textile business, especially in the ever-evolving market of 2025. With a plethora of leading brands and models available, comparing their features and performance metrics becomes essential. Reports from textile industry analysts indicate that companies that invest in advanced ring spinning technology can achieve productivity increases of up to 15%, while improving yarn quality significantly. Notably, parameters such as spindle speed, energy consumption, and automation features play a pivotal role in determining the best fit for specific production needs.

When assessing the capabilities of various machines, it is critical to consider factors such as operational efficiency and maintenance requirements. For instance, modern models often incorporate smart technology, enabling predictive maintenance and minimizing downtime. Data suggests that manufacturers who utilize machines with integrated IoT capabilities can reduce maintenance costs by as much as 20% annually. Moreover, comparing the yarn production quality across different brands can reveal significant variations; companies that prioritize R&D in their machine design report higher customer satisfaction rates linked to product consistency. Thus, a thorough evaluation that considers production output, maintenance demands, and technological advancements will guide textile businesses in selecting the most suitable ring spinning machine for their future operations.

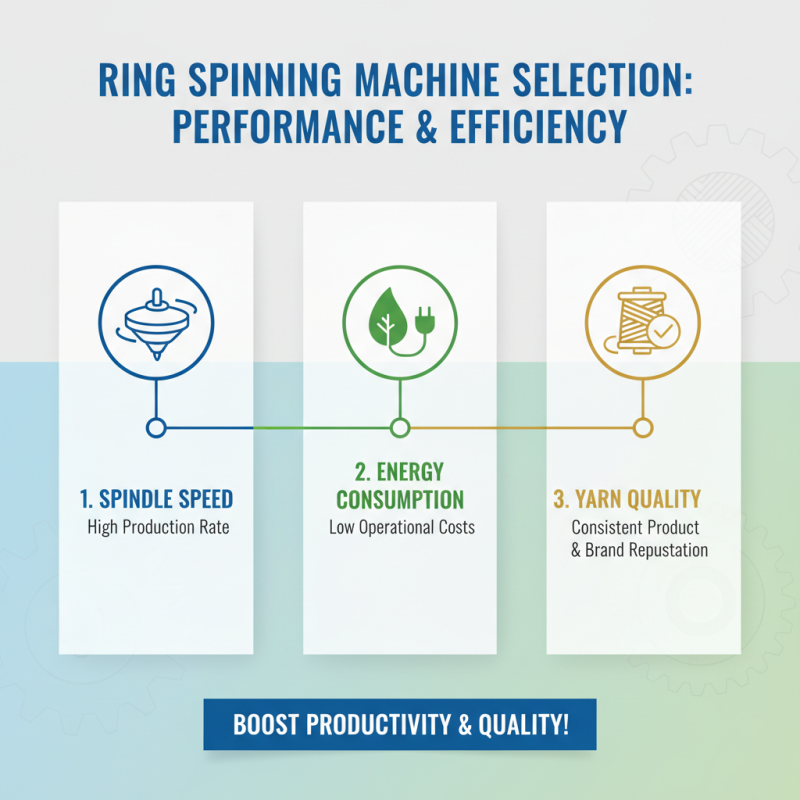

When selecting a ring spinning machine for your textile business, evaluating performance metrics and efficiency is crucial. The right machine can significantly impact your overall productivity and product quality. Key performance metrics to consider include spindle speed, energy consumption, and yarn quality. High spindle speed contributes to increased production rates, while efficient energy usage helps keep operational costs low. Additionally, the machine's capability to produce yarn of consistent quality can enhance your brand's reputation and meet market demands effectively.

Tips to enhance your evaluation process include assessing the machine's technical specifications, reviewing energy efficiency ratings, and analyzing user feedback. Engage with current users of different machines to gain insights into real-world performance and any challenges they faced. It's also beneficial to consider machines that offer ease of operation and maintenance, as this can lead to minimal downtime and lower labor costs.

Finally, don’t overlook the importance of after-sales support from manufacturers. A strong support network can help you resolve issues quickly and ensure that your spinning operation remains efficient. By carefully examining these factors, you can make an informed decision that aligns with your business goals and helps you stay competitive in the textile industry.

When planning to invest in ring spinning machinery for your textile business, budgeting is a crucial step that can't be overlooked. Start by determining your overall budget, which should encompass not only the cost of the machines themselves but also additional expenses such as installation, training, and ongoing maintenance. It's essential to conduct a thorough analysis of your finances, taking into account your current revenue, projected growth, and any potential financing options. This comprehensive approach will help you avoid unforeseen costs and create a realistic expenditure plan.

Investment planning should also consider long-term benefits versus immediate costs. While cheaper machines may seem appealing at first, they could lead to higher operational costs and lower efficiency over time. It's wise to assess the potential return on investment (ROI) for each piece of machinery. Consider factors such as energy efficiency, production speed, and product quality—attributes that significantly affect your bottom line. Engaging with industry experts or consultants can provide valuable insights that help to align your investment decisions with your business goals for 2025 and beyond.