Leave Your Message

Choosing the right machines for the textile industry is crucial for success. As noted by John Smith, an expert in Textile Industry Machines, "The efficiency of your operation hinges on the technology you select." This highlights the importance of making informed choices.

Textile Industry Machines vary widely, from weaving looms to dyeing machines. Each type serves a unique purpose and can impact production quality. It's imperative to assess your specific needs. The wrong machine can lead to inefficiencies and wasted resources.

Many businesses overlook crucial factors. Budget constraints, maintenance needs, and technology updates often get ignored. Investing in high-quality machines may seem costly at first, but it can lead to long-term savings. Reflecting on your choices and their consequences is essential for sustainable growth.

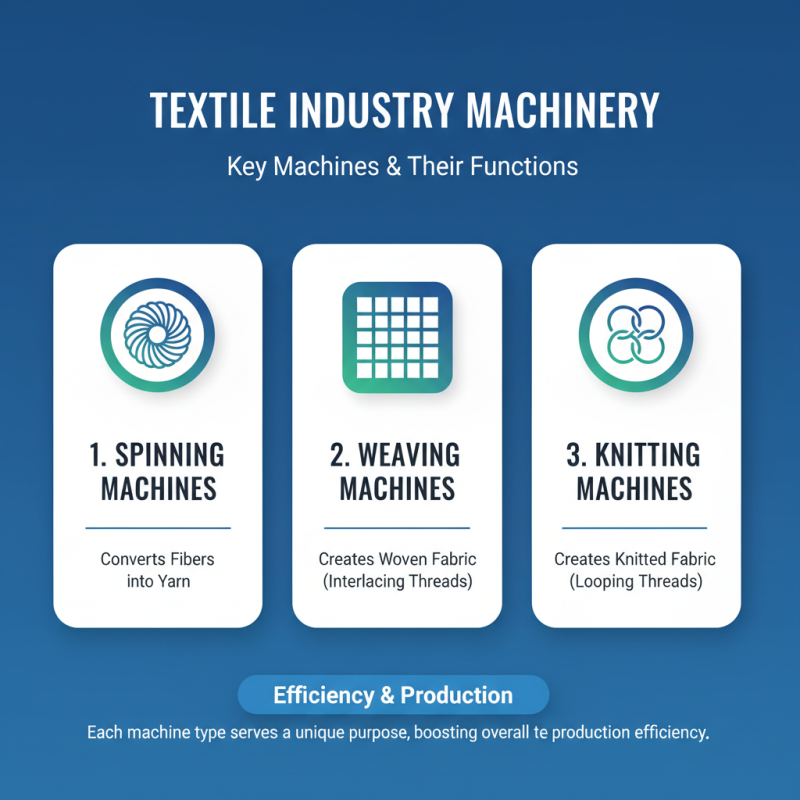

In the textile industry, machines play a crucial role in production processes. Different types of machinery cater to specific needs. Spinning machines convert fibers into yarn, while weaving and knitting machines create fabric. Each machine type serves a unique purpose and contributes to the overall efficiency of textile production.

Understanding the distinctions between machines is essential. For example, weaving machines vary in complexity, from simple shuttle looms to advanced jacquard looms. Each choice impacts fabric quality and design possibilities. In addition to weavers and spinners, there are finishing machines. These machines enhance the fabric’s texture and appearance, adding value to the final product.

When selecting machines, it's important to consider production volume and type of fabric. Some machines may have a steep learning curve. Investing in the wrong type can lead to inefficiencies. Reflecting on past decisions can help avoid mistakes in future purchases. Understanding the demands of your specific production needs is vital for success in the competitive textile market.

Assessing production needs is crucial in the textile industry. Understanding the volume of fabric required will guide your machine selection. Consider the types of fabrics you will produce. Are they lightweight or heavy? This decision affects the kind of machines you'll need. Balancing efficiency and versatility is key.

Next, think about production capacity. How many units do you plan to produce daily? High-output machines may seem appealing but come with higher costs. Smaller setups can be efficient for medium volumes. Reflect on your current operations and future growth. Will your machinery adapt to changing demands?

Investing in the right machines is not always straightforward. It’s easy to get swayed by seen trends or flashy features. However, you might end up with equipment that doesn't meet specific needs. Take the time to analyze your production workflow. Identify bottlenecks or shortcomings in your process. It’s an opportunity to reevaluate your choices and make informed decisions.

Choosing the right machines for the textile industry involves careful evaluation of technology and features. A report from the Textile Machinery Association indicates that nearly 70% of production efficiency can be attributed to the proper selection of machinery. Modern textile production demands versatility and speed. Machines must meet varying production needs, from weaving to finishing.

**Tip:** Prioritize machines with adjustable settings to accommodate different fabric types and design requirements. This flexibility can save significant costs in the long run.

Consider energy efficiency as well. According to recent studies, energy costs can account for up to 30% of total operating expenses. Machines that offer energy-saving features can greatly reduce long-term costs. It’s essential to compare power usage specifications when selecting equipment.

**Tip:** Regularly assess the energy consumption of existing machines. This can highlight areas for improvement and prompt necessary upgrades. Remember, maintenance matters. Machines that are not regularly serviced may lead to breakdowns, complicating production schedules.

When selecting machines for the textile industry, budget considerations come first. It's crucial to determine how much you can afford without compromising quality. Evaluate whether you need basic models or advanced ones with additional features. Basic machines can save money, but they may limit production efficiency. Advanced models are more costly and may require higher maintenance.

Cost factors extend beyond the purchase price. Initial investment is important, but operational costs also matter. Consider energy consumption, maintenance expenses, and training requirements. Some machines may seem cheaper up front but incur high energy costs. Regular maintenance can become expensive, leading to unexpected financial burdens.

Reflecting on the choice of machines is key. Ask yourself if the selected machines truly meet production needs. Will they adapt to future demands? Don't overlook potential hidden costs. Sometimes, cheaper options may lead to lower quality output, causing loss in the long run. Balancing immediate costs with future benefits requires careful thought and planning.

| Machine Type | Initial Cost ($) | Maintenance Cost/year ($) | Energy Consumption (kWh/year) | Production Capacity (units/day) | Lifespan (years) |

|---|---|---|---|---|---|

| Sewing Machine | 5,000 | 500 | 120 | 200 | 10 |

| Knitting Machine | 15,000 | 800 | 180 | 150 | 12 |

| Spinning Machine | 20,000 | 1,000 | 250 | 300 | 15 |

| Dyeing Machine | 30,000 | 1,200 | 300 | 100 | 10 |

| Finishing Machine | 25,000 | 900 | 250 | 250 | 12 |

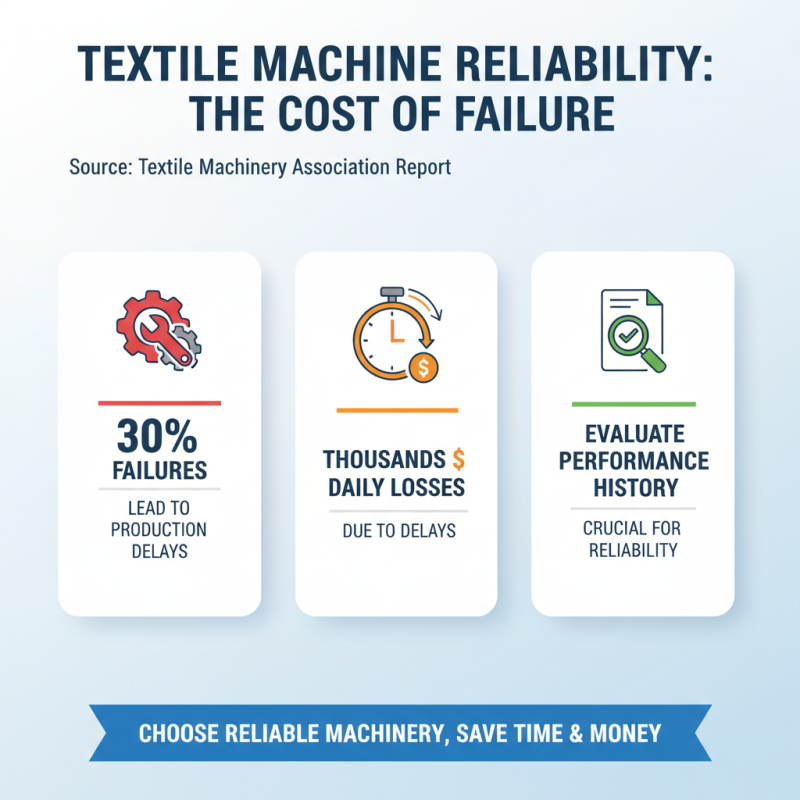

When researching textile machines, reliability is crucial. A report by the Textile Machinery Association highlights that 30% of machine failures lead to production delays. These delays can cost manufacturers thousands of dollars daily. Therefore, evaluating a machine’s performance history is necessary.

Manufacturer support is equally important. A survey indicated that 65% of textile companies prioritize after-sales service. Machines can break down, and having prompt support minimizes downtime. Reliable manufacturers should offer training and easy access to spare parts. A deeper investigation into customer reviews can provide valuable insights into manufacturer responsiveness.

Choosing the right machines involves careful evaluation. Not every machine will perform well in diverse conditions. Some may excel in speed but lack in durability. Engaging with local textile industry experts can help navigate these challenges. Manufacturers’ track records can reveal important trends. Data without context can mislead decisions, emphasizing the need for thorough research.