Leave Your Message

Choosing the right textile processing machine is crucial for business success. The right machine can enhance efficiency and product quality. However, the decision can be overwhelming. Various factors come into play, such as production scale and material types.

Each textile processing machine serves a specific purpose. Some machines are designed for weaving, while others focus on dyeing or finishing. It's important to assess your business's needs before making a choice. Consider the machines’ capabilities. Can they handle the materials you plan to use? Are they compatible with your production process?

Investing in the wrong machine can lead to inefficiencies. You might end up with a machine that cannot meet your production demands. Reflect on your long-term goals. As your business grows, so do your machine requirements. Balancing immediate needs with future plans is vital. Recognizing this challenge can help guide your decision.

Choosing the right textile processing machine hinges on understanding

your business needs and production goals. Analyze your production volume first. Are you a small operation or

a large manufacturer? This affects not only the machinery type but also the technology you might need.

Consider the types of fabrics you will process. Different materials require different machines. For instance,

synthetic fibers might demand higher precision. Evaluate your current

workflow too. Are there bottlenecks that slow production? Addressing these areas can optimize your overall

efficiency. However, investing in new machinery often involves high costs and risks.

What if the machine does not meet your expectations? It's essential to weigh these considerations carefully.

Finally, think about future growth. Your needs may change over time.

Always have flexible options. Can the machine handle new materials or larger volumes if needed? Defining a clear

vision of what you need today, and what you anticipate for tomorrow, is crucial for making an informed decision.

Choosing the right textile processing machine can be challenging. Various types are available, each serving different purposes. To make the best choice, understanding these machines is crucial.

One common type is dyeing machines. They evenly apply color to fabrics. These can vary from small-scale units for local businesses to large industrial machines. Always consider your production needs. If your business grows, you may need a larger machine later.

Another popular option includes cutting machines. They streamline the cutting of fabric into patterns or specific sizes. Precision is vital here. A flawed cut can waste materials and time. Additionally, consider finishing machines that enhance the final product's appearance and quality.

Choosing the right machine isn't always easy. Mistakes can lead to costly lessons. Reflect on your requirements and future growth. Explore the market. A well-informed decision today can save you from trouble tomorrow.

Choosing the right textile processing machine involves understanding key features and specifications that align with your business needs. Start by evaluating the machine’s throughput. A high-capacity machine may seem ideal, but it may not match your production scale. Reports indicate that 45% of small businesses select machines exceeding their requirements, causing inefficiencies.

Another crucial factor is the versatility of the machine. Does it handle various types of fabrics? Machines with limited capabilities could restrict your product offerings. Data suggests that 32% of companies reported losing clients due to inadequate machine functions. Flexibility is often more valuable than merely high performance.

**Tips:** Assess your production goals before purchasing. Determine the types of textiles you plan to process. Make a checklist of must-have features for your industry. Consider future growth needs to avoid costly upgrades later.

Incorporating automation is beneficial, but it's essential to reflect on integration challenges. Many companies face technical difficulties when upgrading to automated systems. Ensure your staff receives proper training to minimize disruptions. Remember, investing in a machine is only part of the equation; proper usage is key to maximizing productivity.

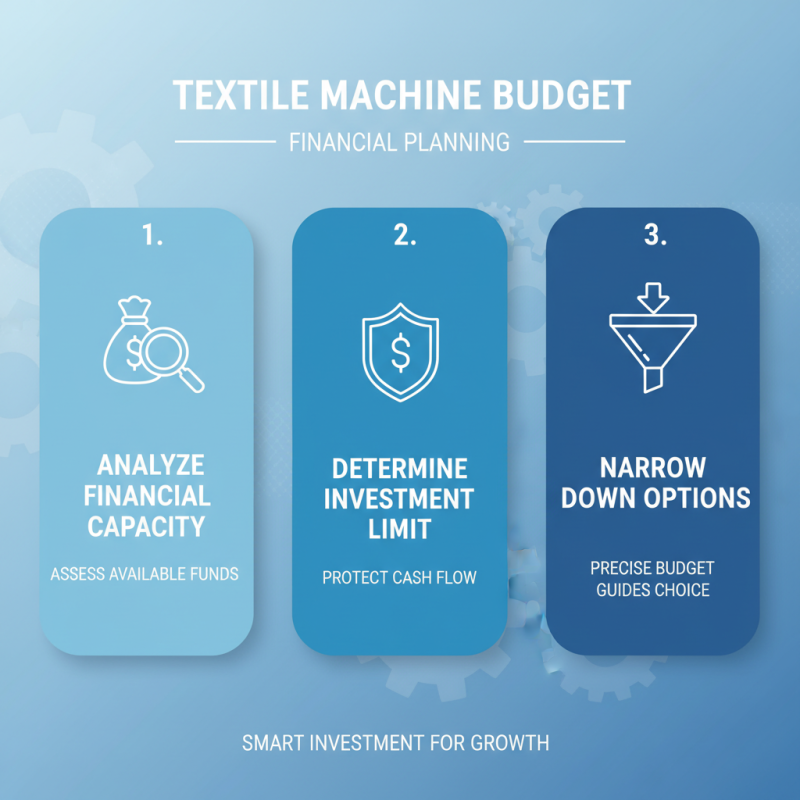

When it comes to selecting textile processing machines, budget considerations are crucial. Analyze your financial capacity. Determine how much you can invest without jeopardizing your cash flow. A precise budget helps in narrowing down options.

Tips: Create a detailed spreadsheet. Include expected costs of machines, maintenance, and operation. This can help visualize the total expense. Aim for machines that offer the best value. But remember, lower cost doesn't always mean better quality.

Return on investment (ROI) analysis is essential. Calculate potential earnings from each machine. Consider the speed and efficiency of the machine. Faster machines can produce more output, leading to higher profits. However, it's important to weigh initial costs against long-term gains.

Tips: Factor in the lifespan of the machine. Will it still serve your needs in five years? Don't overlook maintenance fees. These can add up, affecting your overall profit. Be ready to reassess your choices frequently. Making informed decisions is a continuous process.

When looking for textile processing machines, researching manufacturers and suppliers is crucial. Start by identifying key features that your business needs. Consider the type of textiles you work with. Different materials require different processing techniques. Gather a list of potential machine specifications. Focus on their production capacity and efficiency.

Next, analyze the manufacturers. Look for reviews and testimonials from other businesses. Ask questions about their customer service and support. Availability of spare parts is vital. Local suppliers may offer quicker assistance. It’s often helpful to visit factories if possible. Witnessing machines in action provides valuable insights.

Don’t overlook the importance of comparing quotes. Pricing can vary significantly. However, a lower price doesn’t always mean better value. Consider the long-term costs of maintenance too. Reflect on your specific needs and do not rush the decision. Take your time to evaluate all options carefully before making a choice.