Leave Your Message

In the ever-evolving world of textile manufacturing, the importance of selecting the right Textile Bobbin Machine cannot be overstated. Experts like Dr. Emily Johnson, a renowned textile engineer, emphasize, "A well-chosen bobbin machine can dramatically enhance production efficiency and product quality." This statement highlights the critical role that the proper machinery plays in a successful textile operation.

Choosing the ideal Textile Bobbin Machine involves understanding various factors that can significantly impact overall production dynamics. From understanding the specific needs of your textile processes to evaluating the machine's technical specifications, informed decision-making is crucial. As the industry continues to innovate, staying abreast of the latest developments ensures that manufacturers can make choices that align with their operational goals and market demands. Thus, it becomes imperative for textile businesses to prioritize their selections to remain competitive and effective in their production efforts.

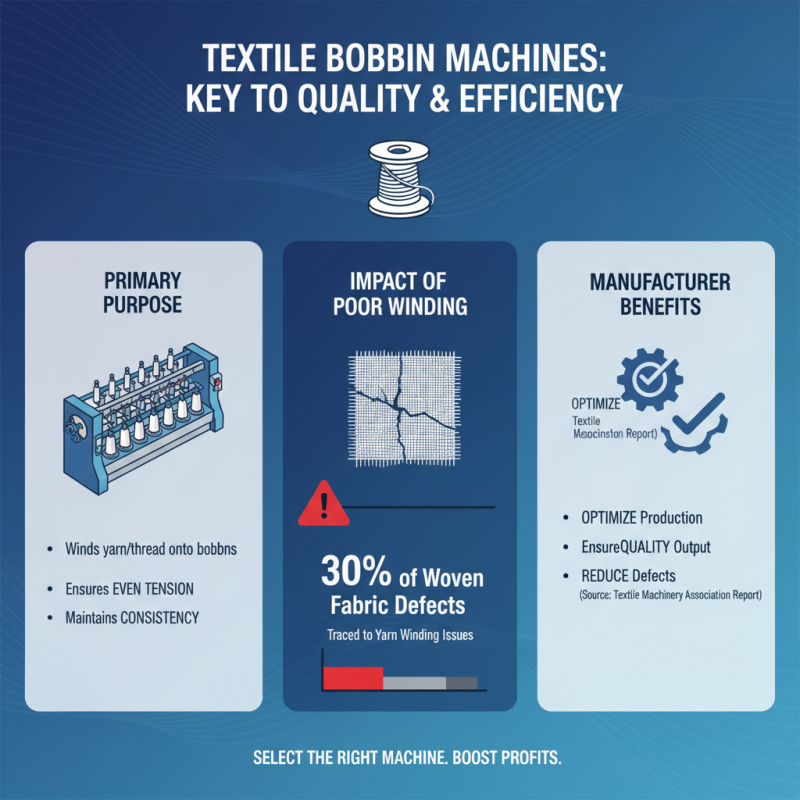

Textile bobbin machines play a critical role in the production process within the textile industry. Their primary purpose is to wind yarn or thread onto bobbins in a manner that ensures even tension and consistency. This process is essential for maintaining the quality of the final textile products, as uneven winding can lead to imperfections during weaving or knitting. According to a report by the Textile Machinery Association, approximately 30% of production defects in woven fabrics can be traced back to issues with yarn winding processes. Therefore, selecting the right bobbin machine is crucial for manufacturers aiming to optimize efficiency and ensure high-quality outputs.

Moreover, the advancements in textile bobbin machine technology have significantly impacted productivity levels across the industry. Modern machines are equipped with features such as automatic tension adjustment and electronic monitoring systems, which enhance the precision of the bobbin winding process. Industry data indicates that companies that invest in high-quality bobbin machines can achieve up to a 20% increase in production efficiency and reduce material waste by 15%. This statistic highlights the financial and operational benefits of selecting the appropriate textile bobbin machine, ultimately contributing to a more sustainable and profitable manufacturing environment. Understanding these machines' technical specifications and operational requirements is vital for making informed purchasing decisions in the competitive textile market.

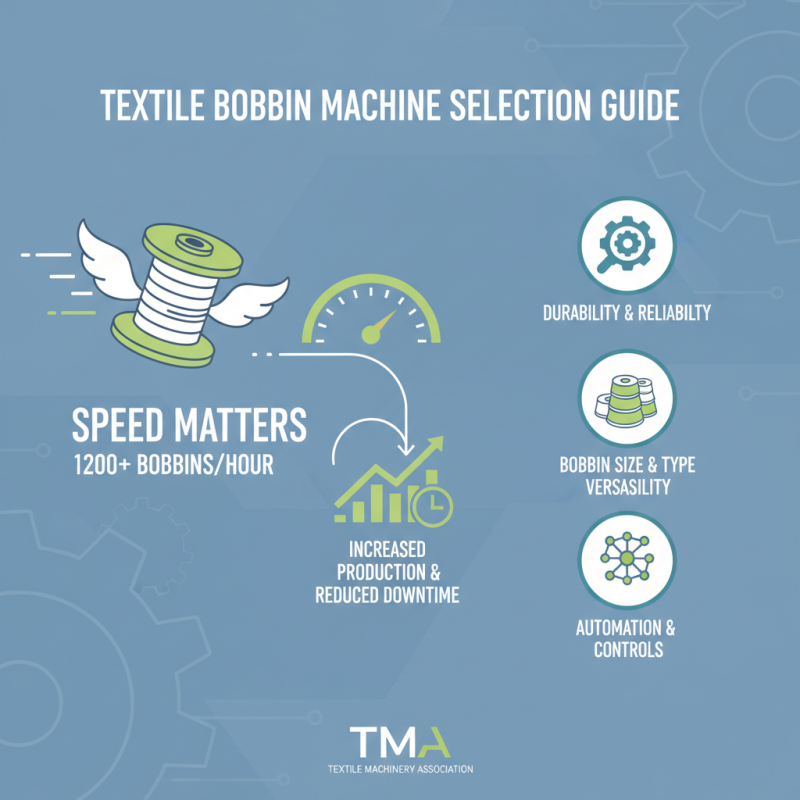

When selecting a textile bobbin machine, there are several key features that must be considered to ensure optimal performance and productivity. First and foremost, the machine's speed is critical. According to the Textile Machinery Association, a significant leap in production efficiency can be achieved by using machines that operate at higher speeds, particularly those that can handle at least 1,200 bobbins per hour. This not only helps to meet increasing demand but also reduces downtime, allowing manufacturers to maximize output.

Another crucial aspect is the precision of the winding process. A 2022 report from the International Textile Manufacturers Federation highlighted that inaccuracies in bobbin winding can lead to costly material waste and lower quality products. Look for machines with advanced tension control systems that can maintain consistent yarn tension, reducing the risk of breaks and distortions. Additionally, user-friendly interfaces and automation capabilities contribute to operational efficiency. Machines equipped with smart technology can monitor performance parameters in real time, enabling quick adjustments and minimizing manual intervention, which can enhance productivity and operational reliability.

In summary, when choosing the right bobbin machine, focusing on speed, precision, and automation features can lead to significant enhancements in manufacturing processes within the textile industry.

When selecting a textile bobbin machine, assessing its compatibility with your textile production lines is crucial. According to industry reports, approximately 30% of production delays in textile manufacturing are attributed to equipment incompatibility. This highlights the importance of ensuring that the machine you choose integrates seamlessly with your existing processes to maintain productivity and efficiency. Look into the machine's specifications to ensure it supports the types of threads and materials you use, such as cotton, polyester, or specialty fibers, to avoid operational disruptions.

Additionally, consider the machine's adjustability and compatibility with your specific production volume and speed requirements. Reports from industry analysts indicate that flexible machinery can enhance throughput by up to 25%, allowing manufacturers to respond quicker to changing market demands. Therefore, investing in a bobbin machine that can accommodate various bobbin sizes and thread types not only streamlines operations but also provides your business with a competitive edge. Thoroughly reviewing these compatibility factors will enable you to make an informed decision that aligns with your production goals.

This chart illustrates the essential factors to consider when choosing the right textile bobbin machine. Each factor is rated on a scale from 1 to 10 based on its importance in textile production, highlighting how compatibility, speed, and customer support are prioritized in the selection process.

When selecting the right textile bobbin machine, evaluating brand reputation and user reviews is crucial. According to a recent industry report by Textiles Technology, over 75% of textile manufacturers prioritize supplier credibility when making purchasing decisions. This statistic highlights the importance of established brands that consistently deliver quality machinery and maintain a positive image in the marketplace. Researching a manufacturer's history regarding product durability, customer service, and innovation will aid in making a more informed choice.

User reviews serve as an invaluable resource in assessing the effectiveness of a textile bobbin machine. A survey conducted by the International Textile Manufacturers Federation revealed that nearly 68% of users rely on peer reviews before equipment purchases. These reviews provide insights not typically found in product specifications, such as real-world performance, ease of maintenance, and potential operational challenges. Engaging with online forums and industry communities can offer additional perspectives and firsthand experiences that facilitate informed decision-making, ensuring that you choose a machine that meets your production needs efficiently.

When considering the purchase of a textile bobbin machine, budgeting plays a crucial role. Establishing a solid budget helps in narrowing down the options that align with your financial constraints while ensuring that you do not compromise on quality. Start by determining the essential features you need from the machine, as these will impact the overall cost. For instance, additional functionalities such as adjustable speed or automatic threading may result in a higher price tag. It's important to balance your requirements with the available budget by focusing on machines that offer the best value for the features needed.

Moreover, it's wise to account for not only the initial investment but also the long-term operational costs associated with the bobbin machine. Regular maintenance, spare parts, and energy consumption can significantly affect your total expenditure over time. Additionally, consider whether investment in a more advanced model will result in increased efficiency, ultimately saving costs in production in the long run. By thoroughly evaluating these financial aspects, you can make an informed decision that aligns with your business goals while ensuring the longevity and productivity of your textile operations.

| Tip Number | Consideration | Cost Range (USD) | Notes |

|---|---|---|---|

| 1 | Machine Type | $1,000 - $3,000 | Consider mechanical vs. electronic. |

| 2 | Production Capacity | $2,000 - $5,000 | Higher capacity usually costs more. |

| 3 | Ease of Use | $500 - $2,000 | Look for user-friendly interfaces. |

| 4 | Maintenance Costs | Varies | Consider ongoing service contracts. |

| 5 | Warranty and Support | N/A | Check warranty length and coverage. |

| 6 | Spare Parts Availability | N/A | Assess availability and cost of spare parts. |

| 7 | User Reviews | N/A | Research opinions from current users. |

| 8 | Energy Efficiency | May save costs | Consider energy-saving features. |

| 9 | Brand Reputation | N/A | Established brands may offer reliability. |

| 10 | Total Cost of Ownership | Consider all factors | Analyze long-term costs vs. initial price. |