Leave Your Message

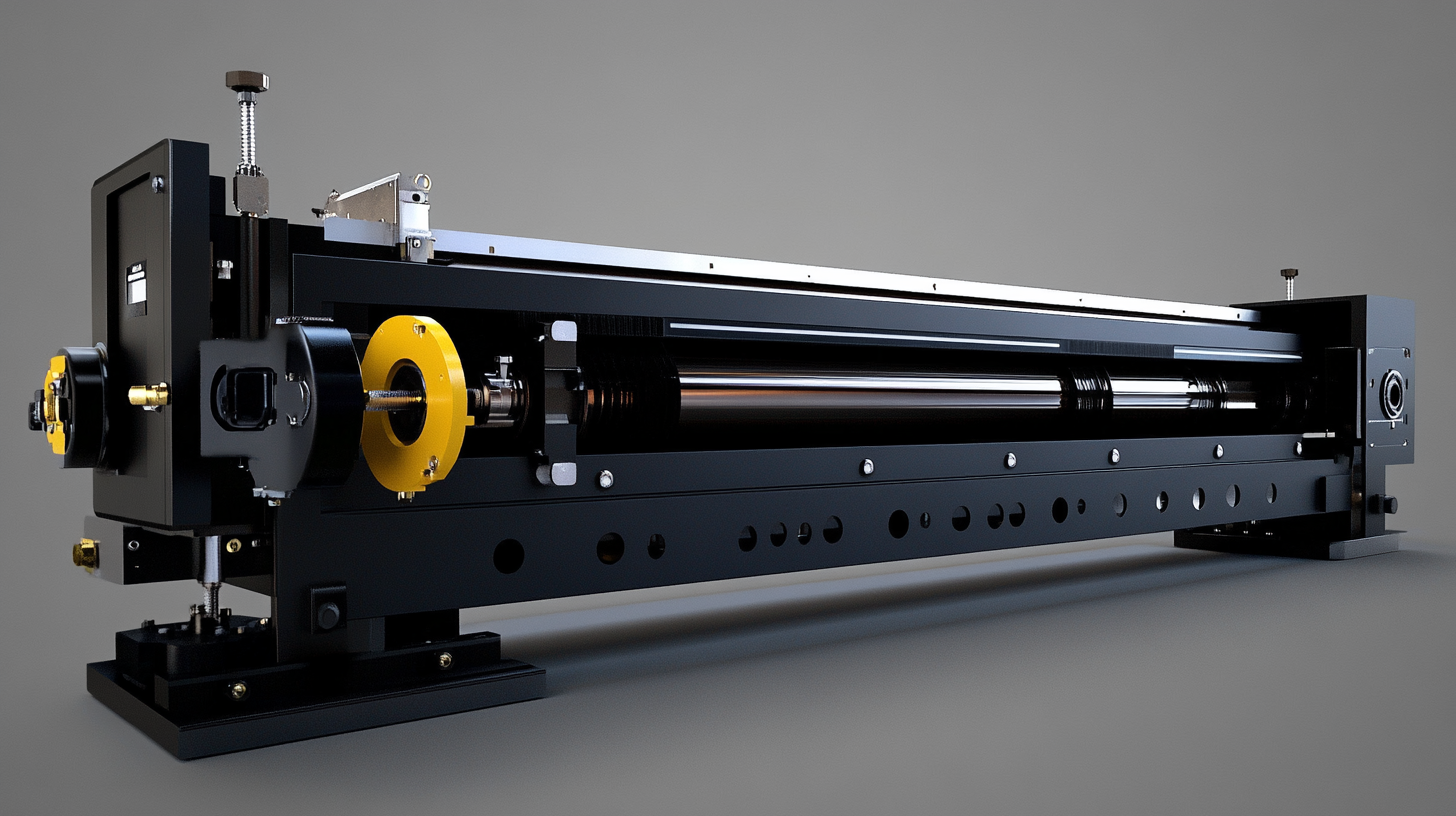

As we move further into the 21st century, the landscape of manufacturing continues to evolve, particularly in the realm of crimping technology. The quest for enhanced efficiency and effectiveness in production has led to the exploration of innovative alternatives to traditional methods, including the esteemed Professional Crimper Machine. By 2025, advancements in design and functionality promise to redefine industry standards, providing new opportunities for manufacturers to adopt cutting-edge solutions that could outperform the best crimping machines available today. This blog delves into the future innovations expected in crimping technology, examining how these developments aim to not only meet but exceed current industry production standards, ultimately reshaping the way we think about crimping processes. As we explore these technologies, we will consider the potential impacts on productivity, precision, and cost-effectiveness for professionals across various sectors.

The crimping technology sector is set to experience significant innovations by 2025, driven largely by market growth trends and emerging technologies. The anticipated expansion in the hoses market, projected to reach USD 28.25 billion by 2032, underscores the growing demand for efficient and reliable crimping solutions in various industrial applications. As industries increasingly adopt automation and smart technologies, the need for advanced crimping machinery that can enhance productivity and ensure precision is becoming critical.

The crimping technology sector is set to experience significant innovations by 2025, driven largely by market growth trends and emerging technologies. The anticipated expansion in the hoses market, projected to reach USD 28.25 billion by 2032, underscores the growing demand for efficient and reliable crimping solutions in various industrial applications. As industries increasingly adopt automation and smart technologies, the need for advanced crimping machinery that can enhance productivity and ensure precision is becoming critical.

In this landscape of evolving needs, manufacturers are likely to focus on developing professional crimper machines that not only adhere to higher efficiency standards but also integrate advanced features such as smart connectivity and real-time monitoring. Innovations in materials and design will also play a crucial role, as companies seek to create crimpers that are not only durable but also adaptable to various applications. These trends indicate a competitive market, where adaptability and technological advancements will define the leaders in crimping technology by 2025.

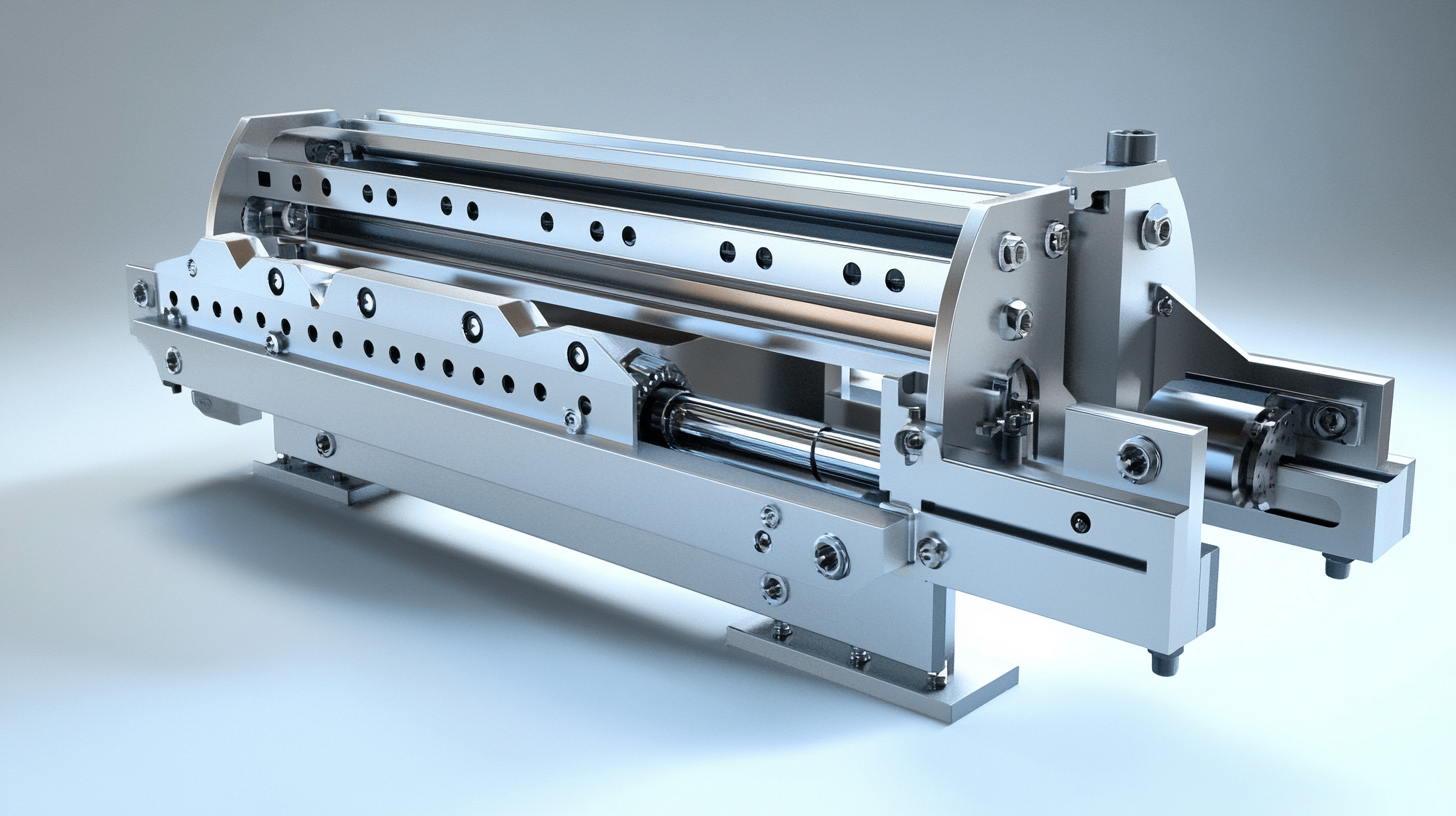

In the ever-evolving landscape of manufacturing, automated crimping solutions are emerging as a game changer, significantly enhancing efficiency and precision in operations. As industries continue to seek ways to streamline production processes, the adoption of advanced crimping technology has become indispensable. Automated crimpers offer precise control over the crimping process, reducing the risk of human error and ensuring consistent quality in every crimp. This precision leads to more reliable connections in critical applications, making automated solutions particularly attractive to manufacturers looking to maintain compliance with stringent industry standards.

Moreover, the integration of smart technology into crimping machines further enhances their functionality. With real-time monitoring and data analytics, manufacturers can now track the performance of their crimping operations, allowing for predictive maintenance and reducing downtime. As businesses increasingly prioritize lean manufacturing principles, the ability to automate crimping can lead to significant cost savings and increased throughput. By 2025, as these automated solutions become more accessible and affordable, we can expect a widespread transformation in the crimping industry, paving the way for innovative practices that will redefine manufacturing effectiveness.

| Feature | Current Technology | Future Innovation (2025) | Benefits |

|---|---|---|---|

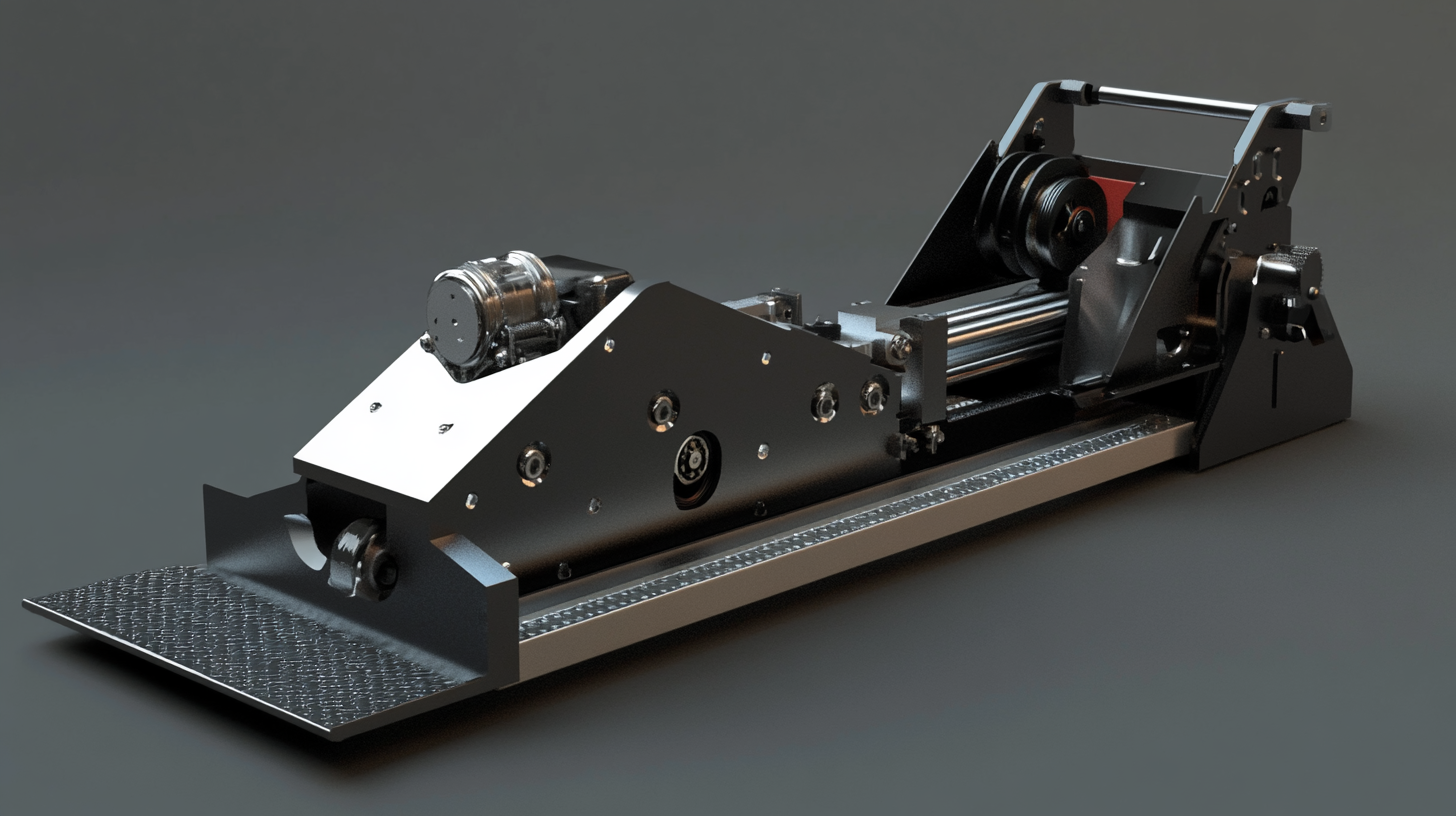

| Automation | Manual crimping devices | Fully automated crimping machines | Increased throughput and reduced labor costs |

| Precision | Basic mechanical calibration | Smart technology with AI algorithms | Higher accuracy and reduced waste |

| Data Integration | Limited data tracking | IoT-enabled data analytics | Better decision-making and predictive maintenance |

| Versatility | Specific type crimping tools | Multi-format crimping systems | Ability to handle various materials and designs |

| User Interface | Basic gauge displays | Touchscreen interfaces with user-friendly controls | Improved user experience and training time |

Sustainability has become a pivotal focus in the development of crimping technology, paralleling the transformation seen in industries like fiber-reinforced composites. According to a review on sustainable FRP composites, the emphasis on eco-friendly materials and manufacturing processes is fostering innovation in various fields, including crimping equipment. As the demand for environmentally responsible alternatives grows, market players are increasingly incorporating sustainable materials into their product lines, aiming to reduce lifecycle impacts.

The hoses market is projected to reach USD 28.25 billion by 2032, highlighting a strong trend toward expansion in industries reliant on high-quality, durable materials. This growth signals an opportunity for crimping technology manufacturers to pivot towards sustainable practices. Adopting eco-friendly crimpers, which utilize renewable resources and have a lower carbon footprint, can not only meet market demand but enhance brand reputation.

Tip: When considering crimping tools, look for those made from sustainable materials or those that are designed for energy efficiency. Always check if the manufacturer prioritizes eco-friendly practices in their production processes. Additionally, opting for tools that are durable and require less frequent replacement can contribute to a more sustainable approach in your operations.

As we look towards the future of crimping technology, the performance metrics of leading professional crimper machines play a vital role in determining which machines will stand the test of time and innovation. A comparative analysis reveals key factors such as speed, precision, and versatility. For instance, machines that integrate advanced microprocessor controls tend to deliver superior accuracy, reducing the risk of faulty connections. Furthermore, the speed at which a crimper can operate directly impacts productivity, making it essential for professionals to choose machines that balance power with efficiency.

In addition to traditional performance metrics, the inclusion of smart technology can greatly enhance the capabilities of crimping machines. Features such as real-time monitoring and diagnostic tools allow for proactive maintenance, ensuring machines operate at peak performance. As more manufacturers adopt innovative materials and design techniques, the competitive landscape will shift, pushing existing market leaders to adapt or risk obsolescence. Ultimately, a thorough understanding of these metrics will empower professionals to select the best crimper machines for their specific needs, paving the way for a new era of efficiency and innovation in the industry.

As industries evolve, crimping technology is becoming increasingly integral to manufacturing processes. A recent report from MarketsandMarkets predicts that the global crimping tool market is expected to grow from $17.6 billion in 2020 to $24.3 billion by 2025, highlighting the rising demand for reliable and efficient crimping solutions across various sectors. Case studies are emerging that reflect innovative applications of crimping techniques, particularly in the automotive and aerospace industries, where precision and durability are paramount.

For instance, a prominent automotive manufacturer recently implemented advanced crimping methods that minimize product failure rates by 30%. This shift not only enhanced the overall quality of their components but also streamlined production time by approximately 15%. Similarly, in the aerospace sector, a leading manufacturer adopted a robotic crimping solution that improved processing accuracy and reduced labor costs by over 20%. These examples demonstrate that embracing innovative crimping technologies can lead to substantial efficiency gains and cost savings, reinforcing the necessity for businesses to stay ahead in this rapidly advancing field.