Leave Your Message

In the rapidly evolving landscape of textile manufacturing, the integration of Water Jet Machine Textile technology is poised to revolutionize production methodologies. According to a recent market report by Grand View Research, the global waterjet cutting machine market is expected to reach USD 1.26 billion by 2025, driven by increasing demand for precision and efficiency in textile applications. Water jet machines, known for their ability to cut intricate designs without fraying or damaging the fabric, offer a sustainable alternative to traditional cutting methods, reducing material waste by up to 30% (Engineering.com). As the industry seeks innovative solutions to enhance productivity and reduce costs, the future of Water Jet Machine Textile innovations promises not only to reshape operational efficiencies but also to elevate the creative possibilities within the textile sector.

The textile industry is witnessing a significant evolution, particularly driven by emerging water jet technologies that are revolutionizing textile cutting processes. By leveraging the precision and efficiency of water jet machines, manufacturers are able to streamline their operations, reduce material waste, and enhance the quality of finished products. Recent reports estimate that the global water jet cutting machine market is projected to reach $2.5 billion by 2026, reflecting a compound annual growth rate (CAGR) of 7.3% from 2021. This innovation aligns closely with the industry’s growing demand for sustainable and efficient manufacturing processes.

In addition to water jet advancements, the integration of automation and artificial intelligence is transforming the landscape of garment production. With the introduction of advanced technologies, processes such as cutting and sewing are becoming increasingly automated, leading to faster turnaround times and reduced labor costs. This is highlighted by the fact that adopting such technologies can boost productivity by up to 30%, allowing companies to respond more swiftly to market demands. As these advancements continue to shape the industry, businesses are empowered to innovate their textile solutions, embracing a future marked by greater efficiency and sustainability.

Water jet machines are revolutionizing modern textile production, offering key benefits that have reshaped the industry landscape. One of the primary advantages is their ability to cut various fabrics with precision and minimal waste. According to a report from Markets and Markets, the global waterjet cutting market is projected to grow from USD 1.9 billion in 2021 to USD 3.1 billion by 2026, demonstrating the increasing reliance on water jet technology in various sectors, including textiles.

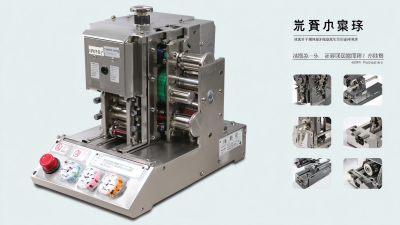

These machines not only enhance precision but also improve efficiency in production. Water jet cutting eliminates the need for mechanical dies, enabling manufacturers to produce intricate designs without extensive setup time. Moreover, the cold cutting process minimizes thermal distortion, ensuring the integrity of delicate fabrics. Data from a recent textile innovation report highlights that manufacturers using water jet systems have seen a 15% reduction in overall production costs while increasing their output by up to 25%.

**Tip 1:** Invest in training for staff on operating water jet machines to maximize their potential. A well-trained team can significantly reduce downtime and maintenance costs.

**Tip 2:** Consider integrating water jet cutting into your supply chain for just-in-time production to further enhance efficiency and reduce excess inventory.

The textile industry is witnessing a significant transformation through innovative materials and techniques enhanced by water jet cutting technology. According to a recent report by MarketsandMarkets, the global water jet cutting market is projected to reach $2.24 billion by 2026, growing at a CAGR of 6.62%. This surge can be attributed to the demand for precise and intricate designs in textile manufacturing, where water jet cutting offers unmatched versatility and efficiency.

Water jet machines utilize high-pressure water streams to cut through various fabrics without compromising structural integrity, making them ideal for delicate materials such as silk and organza. Furthermore, the ability to produce intricate patterns without the need for hard tooling significantly reduces waste and turnaround time. Industry leaders are increasingly integrating advanced software that complements water jet technology, which can analyze and optimize cutting patterns for unique textile applications. Innovative materials, such as smart fabrics that incorporate sensors or adaptive textiles, are now being developed with water jet cutting, ensuring that the industry is not only evolving in terms of technology but also in enhancing functional properties of textiles.

| Material Type | Application Area | Cutting Edge Technology | Benefits of Water Jet Cutting |

|---|---|---|---|

| Nylon | Outdoor Apparel | 5-Axis Water Jet Cutting | Precise cuts without fraying |

| Cotton | Home Textiles | Ultra-High Pressure Technology | Eco-friendly, minimal waste |

| Polyester | Fashion Industry | Automated Cutting Systems | Enhanced edge quality, faster production |

| Silk | Luxury Linens | Precision Motion Control | Minimized fabric distortion |

| Composite Fabrics | Performance Gear | Robotic Water Jet Systems | Complex designs and shapes |

The textile industry is witnessing a transformative shift with the integration of water jet technology, notably in nonwoven fabric applications. Recent developments have seen the U.S. Marine Corps spearheading initiatives to create advanced nonwoven composite fabrics, showcasing water jet's capability to deliver high-performance, lightweight materials that can meet the rigorous demands of military applications. These textiles not only enhance functionality but also promise to improve operational efficiency, making them a prime example of how innovative water jet technology is shaping practical solutions in specialized textiles.

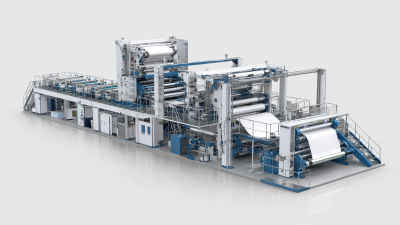

In the realm of weaving, the latest advancements have illustrated the synergy between conventional weaving techniques and water jet machinery. For instance, the demonstration of lining fabric production on cutting-edge Jacquard machines paired with water-jet technology highlights the potential for producing intricate designs with improved efficiency and reduced waste. As textile manufacturing embraces these technologies, the focus on sustainability continues to grow, emphasizing the need for cost-effective and eco-friendly solutions that resonate with the industry's shift towards greener production practices. These case studies and applications exemplify the ongoing innovations that are redefining the textile landscape.

The textile industry is undergoing a significant transformation with the advent of advanced water jet machinery. One of the most promising future trends is the integration of automation and smart technology into water jet systems. These innovations will enable manufacturers to achieve higher precision and efficiency while reducing labor costs. Automated water jet machines can integrate seamlessly with design software, allowing for real-time adjustments and quicker production times. This evolution not only enhances creativity in fabric design but also minimizes waste, making the textile production process more sustainable.

Another trend shaping the future of water jet machinery is the development of eco-friendly materials and processes. As consumers become more environmentally conscious, the industry is responding by adopting sustainable practices. Water jet cutting methods are already known for their ability to use only water and abrasives, reducing chemical usage. The introduction of biodegradable materials in combination with water jet technology promises to further lessen the environmental impact of textile manufacturing. This shift not only meets consumer demands but also positions companies as leaders in sustainability, giving them a competitive edge in a rapidly changing market.