Leave Your Message

In today’s fast-paced manufacturing landscape, the importance of selecting the right tools cannot be overstated, particularly when it comes to the reliability and efficiency of your operations. One such vital tool is the Professional Crimping Machine, which plays a crucial role in ensuring the quality and durability of electrical connections. However, with the plethora of options available on the market, choosing the right crimping machine for your specific needs can be a daunting task. This ultimate guide aims to simplify the decision-making process by providing you with essential tips and insights into the various factors to consider. Whether you are a seasoned professional in industrial applications or a small business owner seeking to enhance your production capabilities, understanding the nuances of different crimping machines will empower you to make an informed choice that aligns with your operational demands. Let’s delve into the key considerations that will pave the way for optimized performance and satisfaction with your investment.

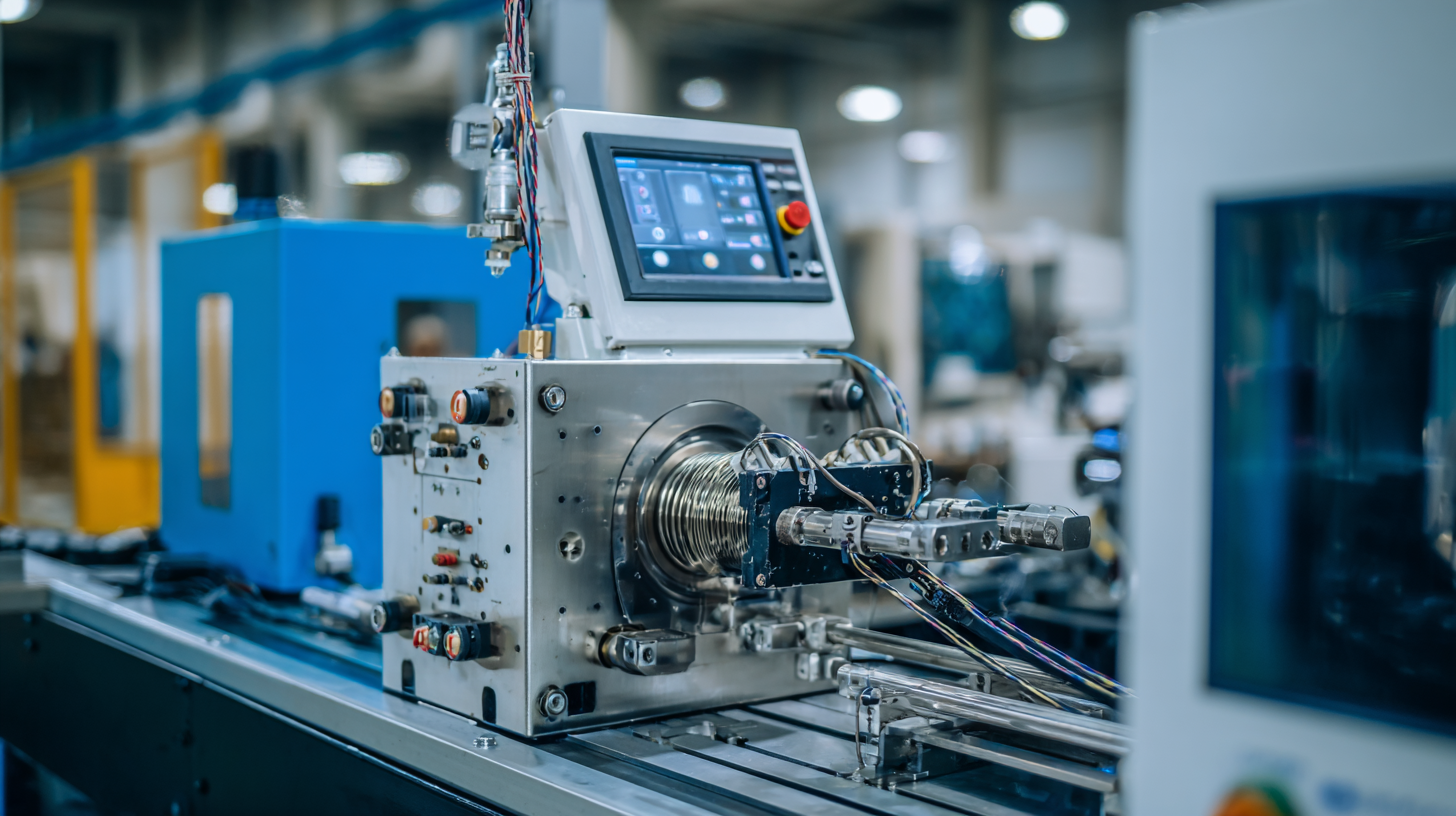

When selecting the right crimping machine for your specific needs, it's essential to understand the various types available. There are generally three main categories: manual crimping machines, semi-automatic crimping machines, and fully automatic models. Manual machines are affordable and perfect for small-scale use, making them ideal for hobbyists or occasional users. Conversely, semi-automatic machines can enhance efficiency with a balance between manual control and automated features, suitable for small businesses. Fully automatic crimping machines are meant for high-volume production, offering speed and precision for industrial applications.

Tip: When considering a crimping machine, assess the materials you'll be working with, as different machines are better suited for various wire gauges and insulation types. Additionally, look into the machine's compatibility with different crimping dies to ensure versatility for future projects.

Tip: It's also beneficial to evaluate the machine's ease of use and maintenance requirements. Machines that are easier to set up and operate will save you time and reduce the likelihood of errors during crimping. Reading user reviews can provide insights into the reliability and performance of specific models.

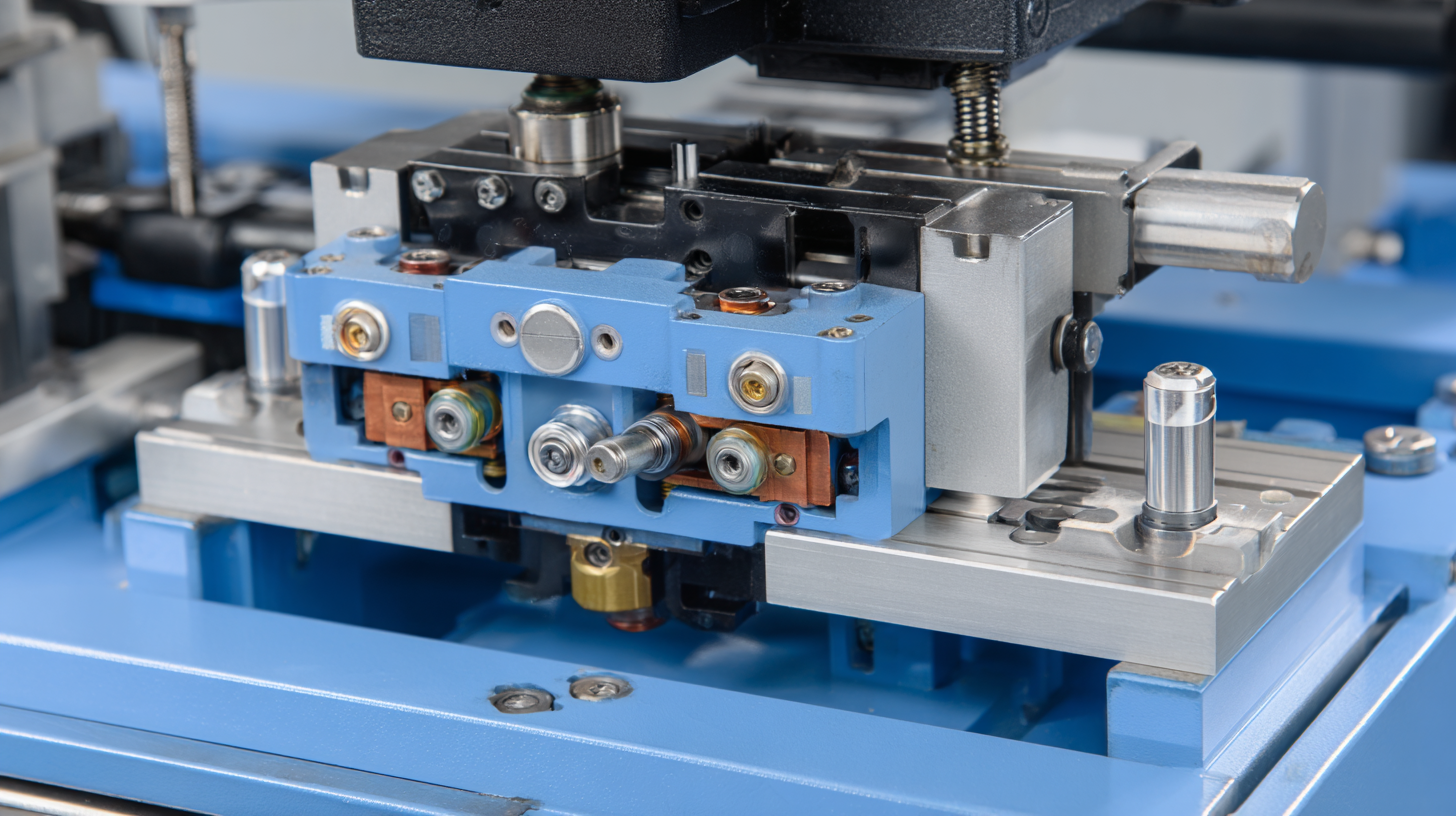

When selecting a professional crimping machine, it is essential to focus on key specifications that directly influence performance and efficiency.

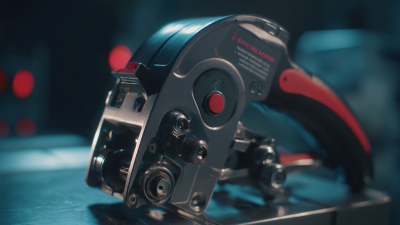

First and foremost, consider the crimping capacity and the types of connectors your projects will require. Different machines offer varying jaw sizes and capacities, which should align with your specific application needs, whether you're working with small electronic components or heavy-duty cables.

Ensuring that the machine can accommodate the gauges and configurations of the connectors you frequently use will enhance your workflow and product quality.

Another crucial specification is the machine's operating speed and cycle time. Depending on your production volume, a faster crimping cycle can significantly boost productivity. Additionally, look for features such as adjustable pressure settings, which allow for fine-tuning based on the materials being crimped.

Ergonomics and ease of use should not be overlooked; a machine that is user-friendly and designed for comfort can reduce operator fatigue and improve consistency across numerous crimping tasks.

By carefully evaluating these specifications, you can select a crimping machine that meets both your technical requirements and operational goals.

When selecting a professional crimping machine, evaluating material compatibility is essential for achieving optimal performance. Different applications may require crimping tools designed for specific materials such as copper, aluminum, or even fiber optics. Understanding the properties of these materials will help you choose the right tool that provides durability and precision, ensuring your crimped connections are strong and reliable.

Tip 1: Always check the manufacturer's specifications for the crimping tool and the materials it supports. This will help you avoid using improper tools that might compromise the integrity of your connections.

Additionally, consider the application environment. For instance, if you are working in harsh conditions, tools that feature corrosion-resistant coatings can offer significant advantages. They not only prolong the life of the tool but also enhance the quality of the crimp, ensuring that your connections stand up to environmental stresses.

Tip 2: Pay attention to the gauge and size compatibility of the crimping tool. Crimping machines usually come with various die sets designed for specific wire gauges, so being aware of the materials and sizes you plan to use will guide your purchasing decision effectively.

When selecting a professional crimping machine, understanding its performance features is crucial for optimizing production efficiency. A high-quality crimping machine not only ensures precise and consistent crimping but also minimizes downtime caused by mechanical failures or subpar performance. Factors such as crimping speed, cycle time, and ease of maintenance play a significant role in the overall efficiency of the production process. Machines that offer quick adjustments and versatile capabilities can adapt to various tasks, thereby streamlining workflow and reducing bottlenecks in production lines.

Moreover, the durability and reliability of a crimping machine significantly impact operational costs. Investing in machines that are engineered with robust materials and advanced technology can lead to significant long-term savings. As production demands increase, machines with superior performance rates can efficiently handle larger volumes without compromising on quality. Therefore, an in-depth analysis of the crimping machine's specifications and performance metrics is essential for making an informed decision that aligns with your production needs, ultimately enhancing efficiency and productivity in your operations.

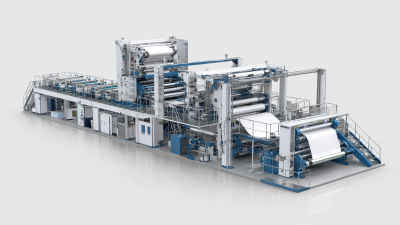

Investing in high-quality crimping equipment can result in significant long-term gains, particularly when considering the latest insights from industry reports. The Asia Pacific hydraulic hose assemblies market is projected to grow substantially between 2025 and 2035, indicating a heightened demand for reliable fluid handling equipment. With a robust crimping machine, businesses can meet the increasing requirements of fluid-based applications across various sectors, enhancing efficiency and productivity while reducing operational downtime.

Conducting a cost-benefit analysis is crucial for manufacturers looking to upgrade or invest in crimping technology. For instance, project reports on automotive radiator manufacturing highlight the importance of capital investment in high-quality machinery, which directly impacts project economics. By choosing the right crimping machine, manufacturers can ensure precision and uniformity, minimizing waste and operational costs in the long run. Furthermore, understanding price tiers—good, better, best—can help producers make educated decisions that align not only with their budget but also with future scalability and reliability in their processes.