Leave Your Message

In today’s fast-paced engineering and electrical fields, effective wire management is crucial for ensuring both safety and efficiency. While the Professional Crimper Machine has long been a staple in the industry for its reliability and precision, the growing demand for innovative tools has sparked interest in alternative solutions that enhance productivity and adaptability. This exploration goes beyond just finding a substitute; it delves into ingenious options that not only replicate the core functionalities of the Professional Crimper Machine but also offer unique benefits tailored to modern wire management needs. As we navigate through these innovative alternatives, we'll consider factors like usability, versatility, and cost-effectiveness, ultimately guiding professionals in their quest for the best solutions to streamline their projects and improve overall wire handling practices.

In today's rapidly evolving landscape, effective wire management has become a fundamental aspect of project execution across various industries. As highlighted by recent developments in the cable sector, such as major expansions and innovative projects, the need for efficient connectivity solutions is paramount. With the Alasia Subsea Cable Project aimed at enhancing digital infrastructure in Syria, it underscores the significance of robust wire management that supports modern communication demands. Proper organization and management of cables ensure not only safety but also optimize the performance of electrical systems, leading to more successful project outcomes.

Furthermore, the emergence of superconducting cables presents a transformative opportunity in high-capacity electrification. These cables, known for their unique capabilities, exemplify the role of cutting-edge technology in improving wire management practices. In utility-scale projects, the meticulous organization of cable geometry influences performance and efficiency, a factor that cannot be overlooked as industries embrace renewable energy and advanced electrical solutions. As projects become increasingly complex, the importance of imagining innovative alternatives for wire management will only grow, fostering a more connected and efficient modern landscape.

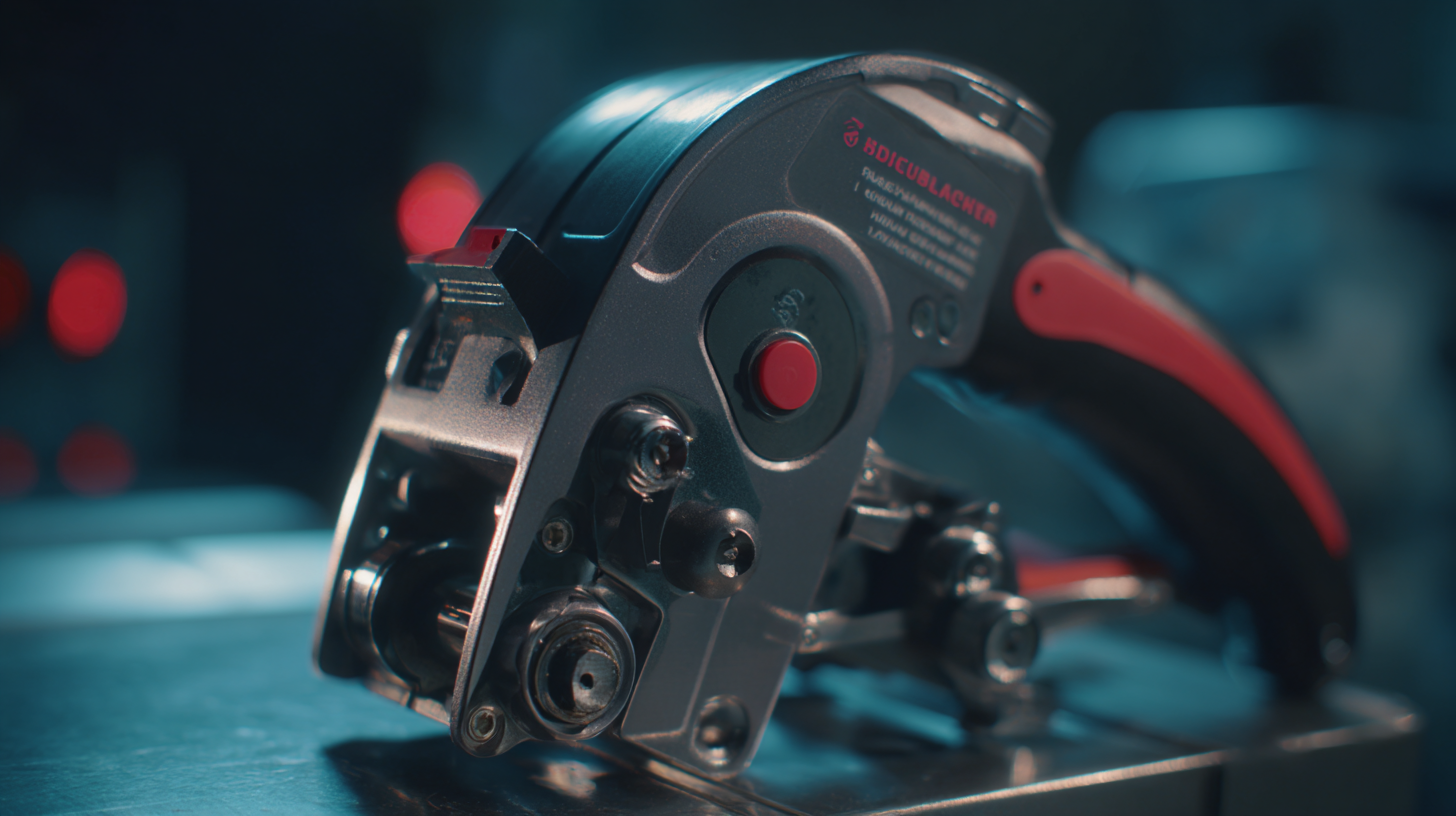

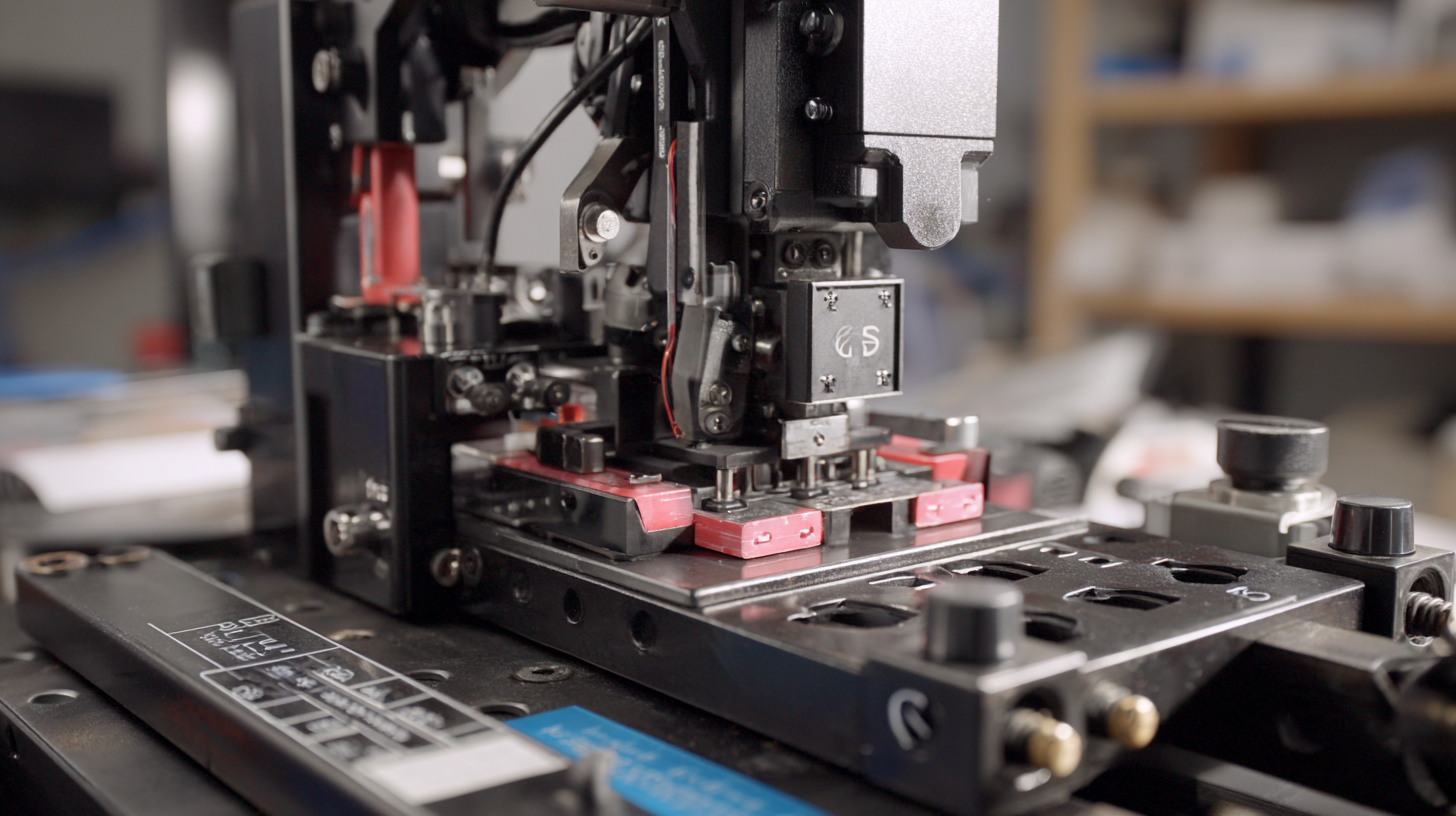

When it comes to efficient wire management, professional crimper machines are essential tools that significantly enhance productivity. These machines are designed with precision, enabling users to create secure and reliable connections quickly. One of the standout features of these crimping devices is their adaptability; they often come with interchangeable dies that cater to different wire sizes and types, allowing users to handle various tasks without needing multiple tools. This versatility not only saves time but also reduces costs associated with purchasing multiple crimpers.

In addition to their adaptability, professional crimper machines often incorporate ergonomic designs that improve user comfort during prolonged use. Many models are equipped with user-friendly features like built-in safety mechanisms, ensuring that even novices can operate them without risk. Furthermore, advanced crimpers offer digital displays and settings that allow for precision adjustments, increasing the quality of the crimp and enhancing the overall durability of electrical connections. Ultimately, the combination of these features makes professional crimper machines indispensable for anyone looking to streamline their wire management processes.

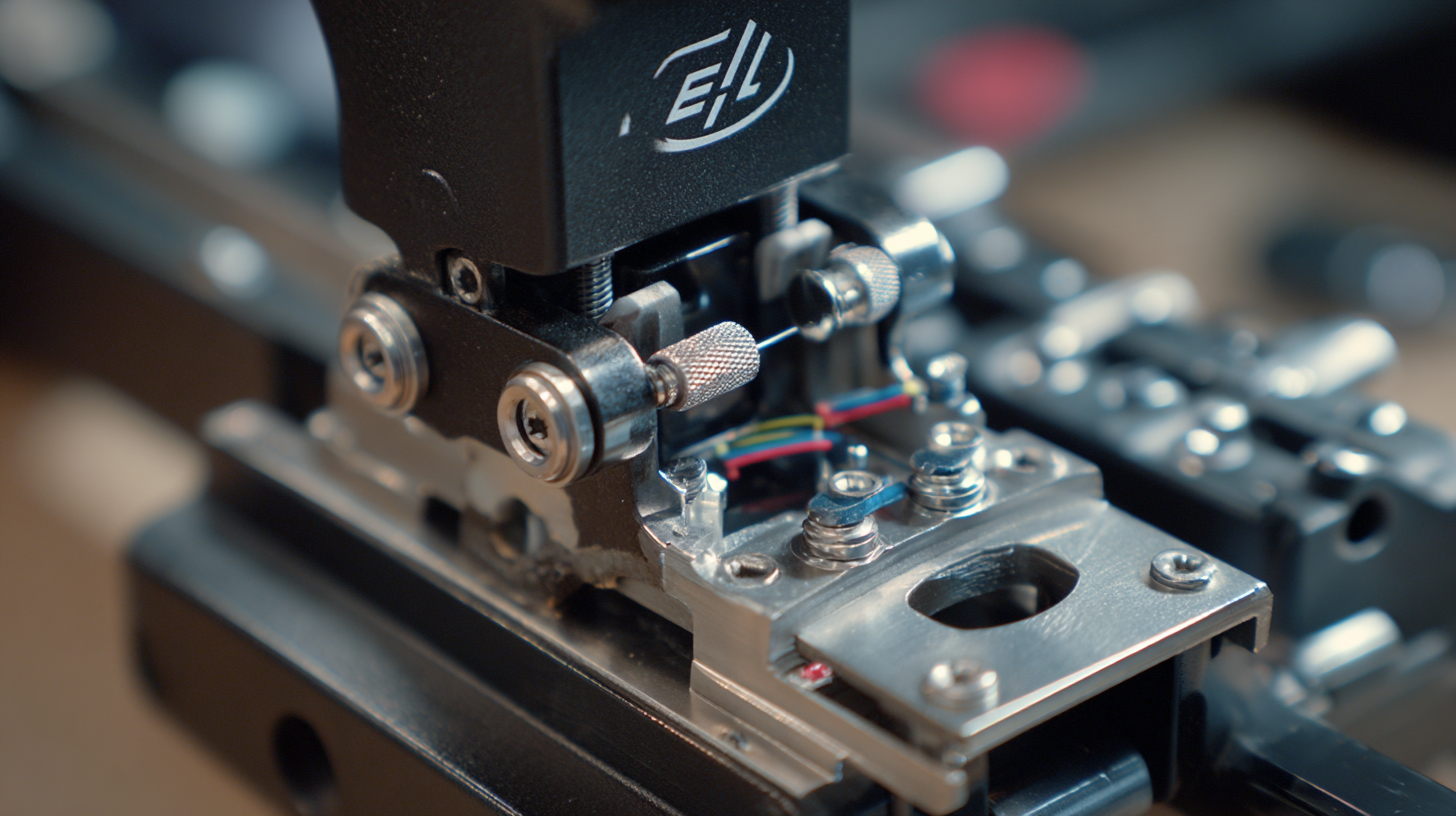

When it comes to effective wire management, the crimping process is essential, and while many professionals lean towards automated crimper machines, manual crimping techniques offer unique advantages worth exploring. Manual crimping tools are often more accessible and cost-effective, making them an ideal choice for small businesses or hobbyists looking to manage wires without investing in expensive machinery. These techniques allow for greater precision, as users can feel and adjust the crimping pressure, ensuring a secure connection every time.

Moreover, manual crimping provides a level of versatility that automated machines might lack. With various styles of connectors and wires, manual tools can adapt to different shapes and sizes, allowing for customization based on specific project needs. Additionally, the tactile feedback received during manual crimping enhances the user’s understanding of the process, making it an educational experience for those developing their skills in wire management. Embracing these innovative alternatives not only empowers users but also helps in fostering a deeper appreciation for the craftsmanship involved in creating secure electrical connections.

| Method | Advantages | Disadvantages | Best Suited For |

|---|---|---|---|

| Manual Crimping Tool | Cost-effective and portable | Requires more physical effort | Small projects or DIY enthusiasts |

| Crimping Jigs | Increases accuracy and efficiency | Can be bulky and less portable | Frequent and repetitive tasks |

| Heat Shrink Tubing | Provides a secure and insulated connection | Requires heat source for application | Electrical projects needing insulation |

| Soldering | Creates a strong and permanent connection | Requires skill and can be time-consuming | Professional projects or electronics |

When it comes to efficient wire management on a budget, there are several DIY tools and techniques that can make a significant difference. For those working on home projects or just trying to keep their workspace tidy, organizing wires can be a daunting task. However, using simple tools like zip ties, cable sleeves, and adhesive clips can help you streamline your setup without breaking the bank. These affordable solutions not only improve aesthetics but also enhance safety by reducing the risk of tripping hazards.

Furthermore, investing time in planning your wire management strategy can yield long-term benefits. For instance, color-coding wires can help you easily identify different connections, while using labeled tags can further simplify troubleshooting. Creating a designated space for cables and cords—such as storage bins or drawer organizers—ensures everything is easily accessible. By combining these tools and strategies, you can maintain a clutter-free environment that promotes both efficiency and creativity in your daily tasks.

When it comes to wire management, choosing the right crimper can greatly influence the efficiency and quality of your work. The debate between electric and manual crimpers often comes down to the specific needs of your project. Electric crimpers are typically faster and provide consistent pressure, making them ideal for high-volume tasks. They require less physical effort, reducing fatigue during extended use. On the other hand, manual crimpers offer greater control and precision for smaller jobs, making them a preferred choice among hobbyists and those in need of a more hands-on approach.

Tips: If you’re leaning towards an electric crimper, ensure that it has interchangeable dies for versatility across different wire sizes. For manual crimpers, look for ergonomic designs that minimize strain on your hands and wrists during prolonged usage. Additionally, consider your workspace; electric crimpers tend to require more space and power considerations than their manual counterparts.

Ultimately, the choice between electric and manual crimpers should align with your working style and the scope of your wire management tasks. Take into account the type of materials you frequently work with and the volume of crimping you expect to do. Test different models to determine which fits your workflow best, and always prioritize safety features, regardless of the type of crimper you choose.