Leave Your Message

Investing in an Automatic Spunlace Line represents a strategic decision for businesses looking to enhance productivity and product quality in the nonwoven fabric industry. According to industry expert Dr. Emily Chen, a leading authority on textile manufacturing, “The integration of advanced technology in automatic spunlace systems not only optimizes production efficiency but also significantly improves the consistency of fabric quality.” This sentiment echoes the growing trend in the textile sector, where automation is becoming a necessity rather than a luxury.

The Automatic Spunlace Line, with its state-of-the-art features, allows companies to streamline their operations and reduce labor costs while meeting the increasing demand for high-quality nonwoven materials. As businesses strive to stay competitive in a rapidly evolving market, the ability to quickly adapt to customer needs and preferences is crucial. Dr. Chen further emphasizes, “Investing in an automatic spunlace line is not just about keeping up with the market; it's about leading it.”

In this context, understanding the benefits and opportunities that come with such an investment is vital for business owners. As we delve deeper into the advantages of the Automatic Spunlace Line, we will explore how it can be a game-changer for your operations, ultimately propelling your business toward sustained growth and innovation.

Investing in an automatic spunlace line can significantly enhance your production capabilities. One of the primary benefits is the increase in operational efficiency. Automatic systems minimize manual intervention, which reduces the likelihood of human error while accelerating production speeds. This not only leads to higher output but also enables businesses to meet growing market demands promptly. Additionally, automated lines often feature advanced technology that ensures consistent product quality, a crucial factor in maintaining customer satisfaction and competitiveness in the market.

Another key advantage is the cost-effectiveness of an automatic spunlace line over time. While the initial investment may be substantial, the reduction in labor costs and waste means that businesses can achieve a quicker return on investment. Moreover, these systems require less maintenance compared to traditional, manual setups. As automation continues to advance, businesses investing in such technology will find themselves better positioned to adapt to changing industry standards and consumer preferences. The long-term savings and improved production capacity ultimately make automatic spunlace lines a wise investment for any company looking to thrive in the textile industry.

Investing in an automatic spunlace line can significantly enhance your business's operational efficiency. As automation continues to transform the manufacturing landscape, spunlace production stands out due to its capability to increase output while reducing labor costs. Reports indicate that automated systems can decrease production time by up to 30%, enabling manufacturers to meet rising demand without compromising quality. This cost-effectiveness is increasingly vital as the market for nonwoven fabrics is projected to grow at a CAGR of 8% from 2023 to 2028, driven by the increasing use of nonwovens in hygiene products and medical applications.

With the ongoing advancements in technology, automatic spunlace lines offer not only cost savings but also the potential for enhanced product consistency and reduced waste. By minimizing human intervention, manufacturers can lower error rates, thereby increasing overall production reliability. The latest machinery in the market leverage 79 years of industry experience, ensuring that investments in automated solutions yield long-term benefits. As the nonwoven sector evolves, companies that embrace such innovations will likely position themselves strategically to capitalize on the sector's growth and the opportunities it presents.

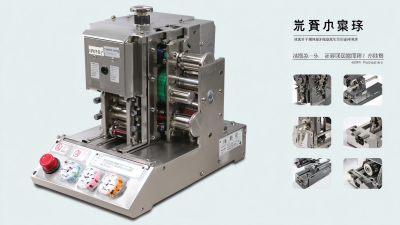

When considering an investment in an automatic spunlace line, it's crucial to know the key features that will enhance your business operations. Firstly, look for high production efficiency. An automatic line should be capable of producing a significant output per hour while maintaining consistent quality. This feature not only boosts your productivity but also optimizes resource utilization, ensuring that your operational costs are kept in check.

Tips for selecting the right spunlace line: Pay extra attention to the technology used in the machinery. Advanced automation features, such as real-time monitoring and adjustments, can dramatically reduce downtime and minimize waste. Additionally, consider the adaptability of the line. A versatile spunlace line that can handle various raw materials will allow you to cater to diverse market needs, enhancing your business's competitive edge.

Another vital aspect to evaluate is the line's ease of maintenance. A user-friendly design that allows for quick repairs and routine servicing can save your team valuable time and effort. Ensure that the manufacturer provides comprehensive support and training, enabling your staff to operate and troubleshoot the machinery effectively. This investment in training pays off by fostering a more skilled workforce, ready to leverage the capabilities of the new equipment.

| Feature | Description | Importance | Expected Benefits |

|---|---|---|---|

| Automation Level | Degree of automation in the production process | High | Increases efficiency and reduces labor costs |

| Production Capacity | Output capability of the line per hour | Medium | Meets business demands and growth needs |

| Energy Efficiency | Energy usage relative to output | High | Lowers operational costs and environmental impact |

| Ease of Maintenance | Simplicity of upkeep and repair processes | High | Reduces downtime and maintenance costs |

| Control System | Technology used for monitoring and control | High | Enhances precision and quality of production |

| Scalability | Ability to expand production in the future | Medium | Facilitates growth and adaptability in market demands |

Investing in an automatic spunlace line can significantly enhance product quality and consistency in manufacturing processes. The use of advanced spunlace technology automates several stages of production, reducing human error and ensuring a higher level of precision. With consistent application of pressure and water jets in the spunlace process, manufacturers can create nonwoven fabrics that meet strict quality standards. This results in products that not only perform better but also maintain uniform characteristics across batches.

Moreover, automatic systems enable manufacturers to monitor and adjust parameters in real time, fostering an optimal production environment. This ability to fine-tune machinery leads to reduced waste and improved material efficiency, which are critical factors in maintaining competitive pricing and meeting market demands. By adopting automatic spunlace technology, businesses can enhance their reputation for quality while also ensuring that their products are reliable and consistent, ultimately driving customer satisfaction and loyalty.

Integrating an automatic spunlace line into your workflow can significantly enhance your operational efficiency. These advanced systems combine innovative technology with streamlined processes, allowing for faster production times and reduced labor costs. By automating key processes such as fabric feeding, web formation, and bonding, businesses can minimize human error and maximize output. This seamless integration not only accelerates production cycles but also enables consistent quality, ensuring that every batch of spunlace fabric meets the highest standards.

To effectively incorporate an automatic spunlace line, it is crucial to analyze your current workflow and identify key areas for improvement. Start by training your team on the new equipment to ensure a smooth transition and optimize its capabilities. Additionally, consider the layout of your production floor; a well-designed workflow can minimize material handling and reduce downtime. By embracing this automation, businesses can capitalize on increased efficiency, ultimately leading to higher profitability and a stronger competitive edge in the market.