Leave Your Message

In today's rapidly evolving textile industry, the importance of adopting advanced technology cannot be overstated. One significant advancement that businesses should consider is the investment in Automatic Viscose Equipment. This technology not only enhances production efficiency but also improves the quality of viscose fibers, which are renowned for their versatility and sustainability. As demand for eco-friendly materials grows, incorporating automatic equipment can position businesses to meet market expectations while optimizing operational workflows.

The integration of Automatic Viscose Equipment streamlines various processes, reducing manual labor and minimizing human error. Additionally, automation contributes to consistent quality control, ensuring that the final products meet the stringent standards required by consumers and regulatory bodies alike. By adopting this technology, companies can significantly cut down production costs and time, allowing them to focus on innovation and expansion.

Moreover, investing in Automatic Viscose Equipment aligns with a future-focused business strategy, paving the way for sustainable practices that are increasingly sought after by eco-conscious consumers. This shift not only bolsters a company’s reputation but also attracts investment opportunities, as stakeholders are more inclined to support businesses committed to sustainability and efficiency. In an ever-competitive landscape, automatic solutions for viscose production represent not just a trend but a pivotal step towards long-term growth and success.

Investing in automatic viscose equipment can significantly enhance efficiency and productivity in textile production. One of the primary benefits of this technology is its ability to streamline the manufacturing process. Automatic systems reduce human error and enhance precision in the production of viscose fibers, leading to a more consistent quality of the final product. This not only minimizes waste but also lowers the overall production costs, allowing businesses to allocate resources more effectively.

In addition to efficiency gains, automatic viscose equipment offers improved operational flexibility. These systems can adapt to varying production requirements, making it easier for manufacturers to respond to market demands and customize their output. As consumer trends shift, businesses equipped with automated solutions can pivot quickly, maintaining a competitive edge.

Furthermore, automation can enhance worker safety by minimizing labor-intensive tasks and reducing the risk of workplace accidents, contributing to a healthier and more productive work environment. Overall, the integration of automatic viscose equipment aligns well with the goals of modern textile production, emphasizing sustainability, efficiency, and innovation.

Investing in automatic viscose equipment proves to be a strategic move for businesses aiming to enhance their operational efficiency and optimize costs. According to a recent report by the Global Textile Machinery Market, the growth of automatic technologies in the viscose industry is projected to increase by over 6% annually. This surge can be largely attributed to the increasing demand for cost-effective production processes. Adopting automatic viscose machinery allows manufacturers to significantly minimize labor costs, reducing them by up to 30% compared to traditional methods.

Moreover, automatic machinery plays a crucial role in reducing waste and improving product quality. Studies indicate that automated systems can decrease material waste by approximately 20% through more precise control of viscosity levels and production processes. This not only leads to substantial cost savings but also aligns with sustainability goals, as lower waste production contributes to reduced environmental impact. In terms of energy efficiency, advanced automatic systems consume up to 15% less power than their manual counterparts, further amplifying long-term savings. Thus, the cost-effectiveness of investing in automatic viscose machinery is not just about initial expenditure; it fundamentally reshapes production capabilities and enhances financial sustainability for businesses within the textile industry.

This chart compares the costs and production outputs of investing in automatic viscose machinery versus manual production methods. The data reflects the initial investment, annual maintenance, labor costs, and production output in tons, illustrating the cost-effectiveness of automation in viscose production.

Investing in automatic viscose equipment is a strategic move that can significantly enhance the efficiency and productivity of your business. According to a report by the International Textile Manufacturers Federation (ITMF), industries that have adopted automated systems have reported productivity increases of up to 30%. This not only accelerates manufacturing processes but also improves the consistency and quality of viscose products. Automation reduces the likelihood of human error and enhances operational precision, allowing businesses to meet increasing demand without sacrificing quality.

Tip: Evaluate your current production processes to identify areas where automation can create value. Investing in equipment that streamlines operations will result in reduced overhead costs and faster turnaround times.

The benefits of automated systems extend beyond just manufacturing efficiency. They also contribute to better resource management. A study by the Textile Research Journal highlights that businesses utilizing automated viscose equipment can reduce material waste by approximately 20%. This efficient use of resources not only lowers costs but also aligns with sustainable practices, which are becoming more crucial in today's market.

Tip: Consider implementing a phased approach to automation, starting with the most labor-intensive processes. This can provide insights into operational improvements and ROI before committing to a full-scale overhaul.

Investing in automatic viscose equipment not only enhances operational efficiency but also addresses pressing sustainability challenges in the textile industry. Traditional viscose production often relies on harmful chemicals and results in significant waste, contributing to environmental degradation. In contrast, modern automatic viscose equipment is designed to minimize resource consumption, ensuring that water usage, energy demands, and chemical waste are substantially reduced. These advancements in technology present a unique opportunity for businesses to align their operations with global sustainability goals while enhancing profitability.

Furthermore, automatic viscose equipment adheres to stricter environmental standards, promoting a cleaner production process. By employing closed-loop systems, it captures and recycles solvents and other byproducts, mitigating hazardous emissions and providing a safer working environment. This commitment to sustainability not only satisfies regulatory requirements but also appeals to increasingly eco-conscious consumers. Businesses that embrace these innovative solutions not only contribute positively to environmental conservation but also enhance their market competitiveness by showcasing their dedication to responsible manufacturing practices.

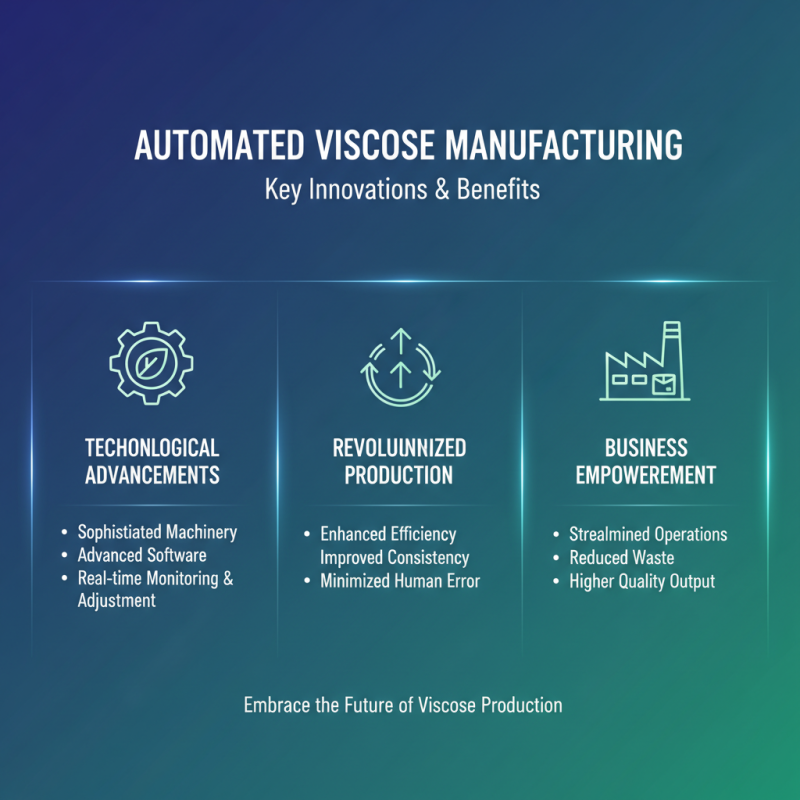

The realm of automatic viscose manufacturing has undergone significant transformations due to technological advancements, making it essential for businesses to embrace these innovations. Automation has revolutionized the production process, enhancing efficiency and consistency while minimizing human error. This shift allows manufacturers to streamline their operations, reduce waste, and meet the growing demand for viscose products more effectively. With sophisticated machinery and software, automatic systems can monitor and adjust production parameters in real-time, ensuring optimal performance and higher quality output.

Moreover, advancements in data analytics and machine learning are further enhancing the capabilities of automatic viscose equipment. By integrating smart technologies, manufacturers can predict maintenance needs, analyze production trends, and optimize resource allocation. This not only leads to cost savings but also enables businesses to adapt swiftly to market changes. As the industry continues to evolve, investing in state-of-the-art automatic viscose equipment becomes a strategic move that positions companies for long-term success in a competitive landscape.