Leave Your Message

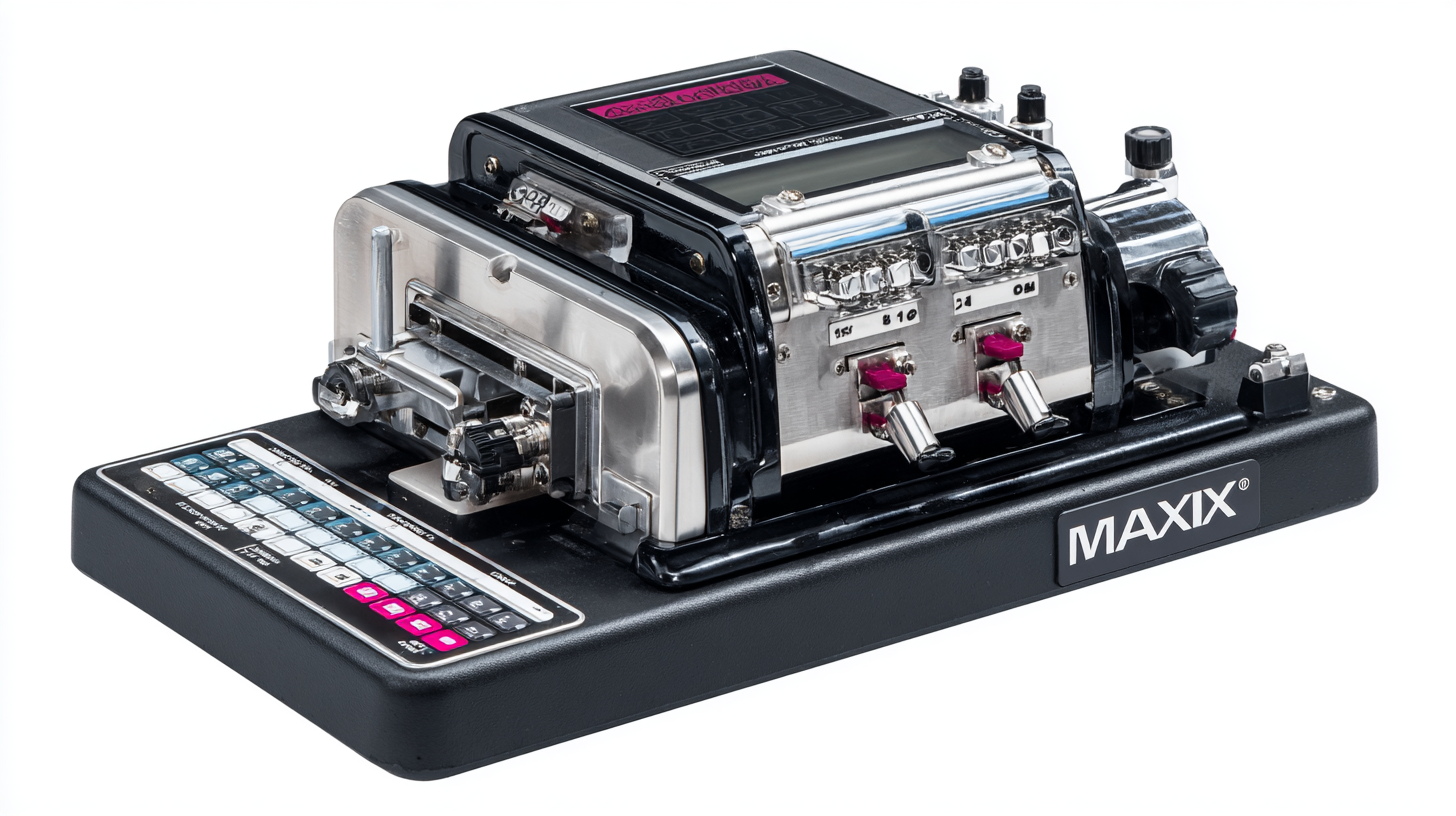

In the fast-evolving landscape of technology, staying ahead requires not just innovative equipment, but also unparalleled support systems. This is especially true when it comes to the use of a Professional Crimper Machine, a vital tool in various industries for ensuring precision and reliability in cable and wire assembly. As we approach 2025, it becomes crucial to understand the trends shaping this sector, particularly the integration of advanced technology and the importance of exceptional after-sales support.

This guide explores how investing in a high-quality Professional Crimper Machine, paired with robust customer support services, can maximize operational value and efficiency. We will also delve into the anticipated technological advancements that will redefine manufacturing practices, ensuring that businesses not only keep pace with the competition but also drive innovation forward.

Professional crimper machines play a crucial role in enhancing efficiency within modern manufacturing. According to a report from MarketsandMarkets, the global market for crimping tools is projected to grow from $1.5 billion in 2021 to $2.2 billion by 2026, reflecting a CAGR of 8.3%. This growth is primarily driven by the increasing demand for precision and reliability in manufacturing processes. The integration of advanced technologies into these machines allows for quicker setups, reducing lead times and improving overall productivity.

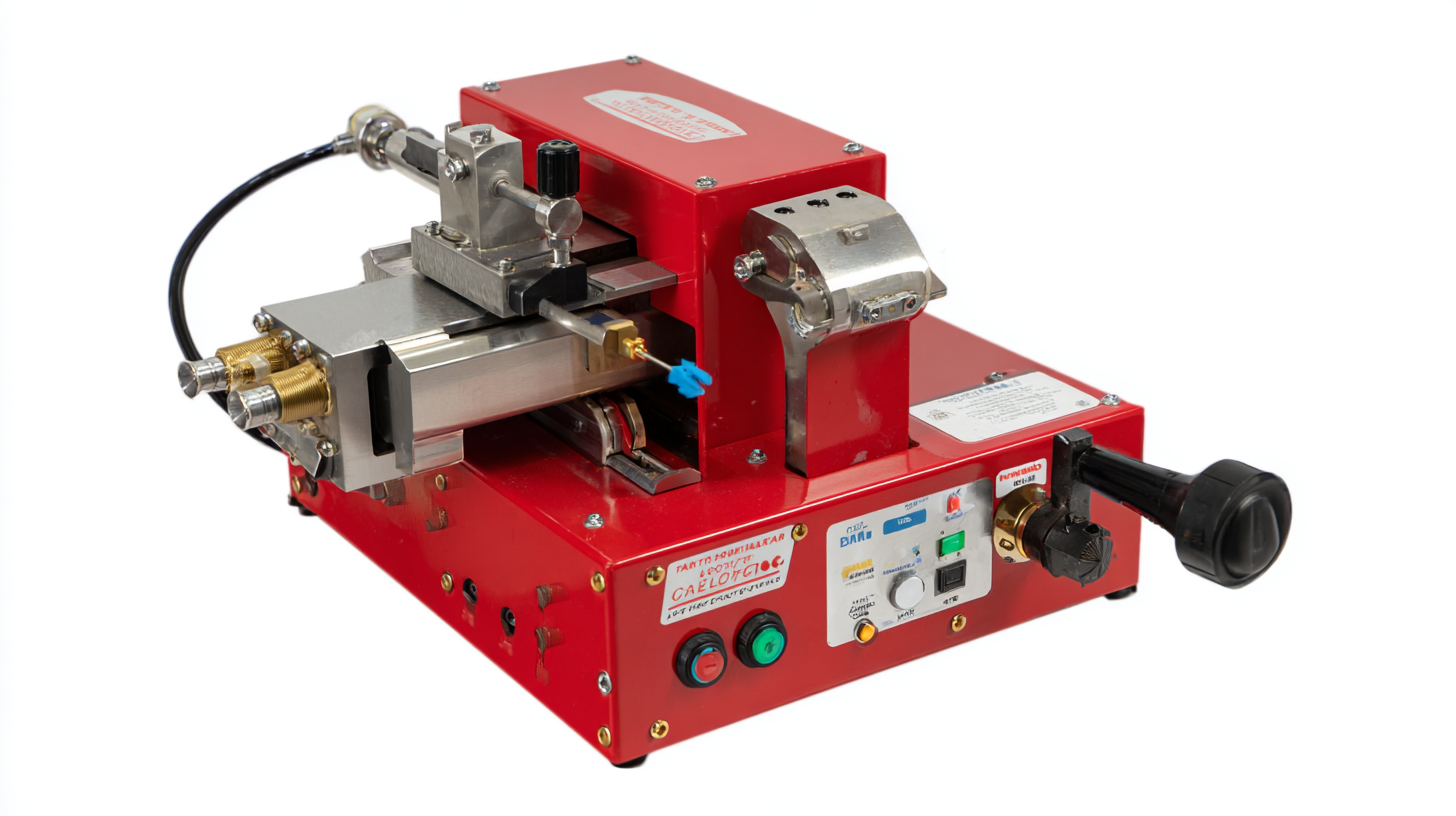

To maximize the utility of professional crimper machines, manufacturers should consider a few tips. First, ensure regular maintenance is performed to keep machines running optimally—this can prevent downtime and maintain consistent production quality. Second, invest in training for operators to enhance their understanding of machine capabilities and troubleshooting, which can significantly reduce errors and improve efficiency. Finally, leveraging exceptional after-sales support can facilitate ongoing performance improvements, ensuring that the machines continue to meet production demands effectively.

As manufacturing landscapes evolve, reliance on high-quality crimper machines will only grow. Organizations that prioritize technological advancements and incorporate best practices in training and maintenance will likely see a substantial boost in operational efficiency and product quality.

Exceptional after-sales support is increasingly recognized as a critical component in enhancing customer satisfaction and retention. Companies that prioritize customer experience and provide responsive support can effectively differentiate themselves in a competitive market. For instance, a study highlighted that existing customers are significantly more valuable than new ones, with returning customers often spending more. This trend underscores the importance of a robust after-sales service that not only addresses customer concerns but also builds lasting relationships.

By investing in exceptional after-sales support, businesses can cultivate loyalty and ensure that their customers feel valued. This strategy enhances the overall customer experience, creating a positive feedback loop that encourages repeat business. As evidenced in various sectors, from retail to professional services, superior customer service sets the foundation for strong retention rates, which can reach up to 84% in certain industries. Therefore, for any brand looking to maximize value, the integration of impactful after-sales support is not just beneficial; it is essential for long-term success.

In the highly competitive market of crimper machines, the significance of quality assurance cannot be overstated. According to a report by MarketsandMarkets, the global crimping machine market is projected to grow from $1.2 billion in 2020 to $1.8 billion by 2025, indicating a robust demand for machines that combine efficiency and reliability. Companies that prioritize quality assurance during production not only ensure their products meet regulatory standards but also enhance their brand reputation. For instance, a recent study revealed that manufacturers with rigorous quality control processes see a 30% reduction in warranty claims, directly impacting their bottom line and customer satisfaction.

Furthermore, exceptional after-sales support is intricately linked to quality assurance in the crimper machine sector. A survey conducted by TechValidate found that 80% of customers considered after-sales support as a critical factor when choosing a vendor. When quality assurance protocols are meticulously followed, the likelihood of machine failures is significantly diminished, resulting in fewer service calls and higher customer retention rates. As crimper machine manufacturers strive to maximize value for their clients, integrating quality assurance into every stage of production and offering unparalleled support can set them apart in a thriving marketplace.

The crimping solutions market is witnessing a significant shift, driven by the increasing demand for high-performance machinery that caters to diverse industrial applications. As industries evolve, the need for reliable and efficient crimping machines has surged, making it essential for manufacturers to stay ahead of market trends. This growth is particularly prominent in sectors like telecommunications, automotive, and electrical manufacturing, where precision and quality are paramount.

To maximize the benefits of a professional crimper machine, businesses should consider implementing a few key tips. Firstly, invest in machines that not only meet current specifications but also allow for future upgrades. This foresight can save costs in the long run while enhancing productivity. Additionally, prioritize suppliers that offer exceptional after-sales support, which is critical for maintaining the longevity and efficiency of your equipment.

Another important aspect is to regularly assess and calibrate your crimping tools to ensure optimal performance. This proactive approach not only minimizes downtime but also ensures that you maintain high standards of quality in your production process. By staying aligned with market trends and emphasizing maintenance, businesses can thrive in the competitive landscape of crimping solutions.

| Region | Market Size (USD Million) | CAGR (%) | Key Trends | After Sales Support Availability |

|---|---|---|---|---|

| North America | 250 | 5.2 | Increase in Automation, Adoption of Smart Technology | Available 24/7 |

| Europe | 200 | 4.8 | Sustainability Initiatives, Preferences for Portable Machines | Available on Weekdays |

| Asia-Pacific | 300 | 6.5 | Rapid Industrialization, Shift to Digital Fabrication | Limited Availability |

| Latin America | 80 | 3.7 | Growing Cable Manufacturing, Need for Cost-Effective Solutions | Available on Request |

| Middle East & Africa | 120 | 4.2 | Investment in Infrastructure, Demand for High-Performance Tools | Available During Business Hours |

In the crimping industry, leveraging China’s manufacturing excellence provides companies with a competitive edge. The nation is renowned for its efficient production capabilities, combining skilled labor and advanced technology to produce high-quality crimper machines at a fraction of the cost compared to other manufacturers. By partnering with established Chinese manufacturers, businesses can access innovative products that meet their specific needs while maintaining affordability.

Tip: When choosing a manufacturer, prioritize those with proven track records in quality control and customer satisfaction. This will ensure that you receive machinery that not only performs optimally but also meets industry standards.

Furthermore, exceptional after-sales support is critical in maximizing the value of your investment. Reliable service ensures that any concerns regarding the crimper machine can be swiftly addressed, extending its lifespan and functionality. Manufacturers that offer comprehensive training, rapid response times, and easy access to spare parts significantly enhance the ownership experience.

Tip: Establish clear communication channels with your chosen manufacturer to facilitate seamless support. Regular maintenance schedules and open dialogues about potential upgrades can preemptively resolve issues before they affect productivity.