Leave Your Message

In the realm of industrial and manufacturing processes, precision and reliability are paramount. A crucial tool that facilitates high-quality manufacturing is the Professional Crimping Machine. This specialized device plays an integral role in creating secure and durable connections between various materials, particularly in industries such as electronics, telecommunications, and automotive. By using a Professional Crimping Machine, manufacturers can ensure that their products meet stringent performance standards, resulting in enhanced safety and longevity.

The operation of a Professional Crimping Machine is both straightforward and sophisticated, utilizing a combination of mechanical engineering and advanced technology. These machines are designed to apply a specific amount of pressure to crimp connectors onto cables or wires, producing a secure and conductive joint. This process not only streamlines production efficiency but also reduces the risk of human error, which can compromise the integrity of the connections. As industries continue to evolve, understanding the functionality and advantages of a Professional Crimping Machine becomes increasingly important for businesses aiming to maintain a competitive edge in their respective markets.

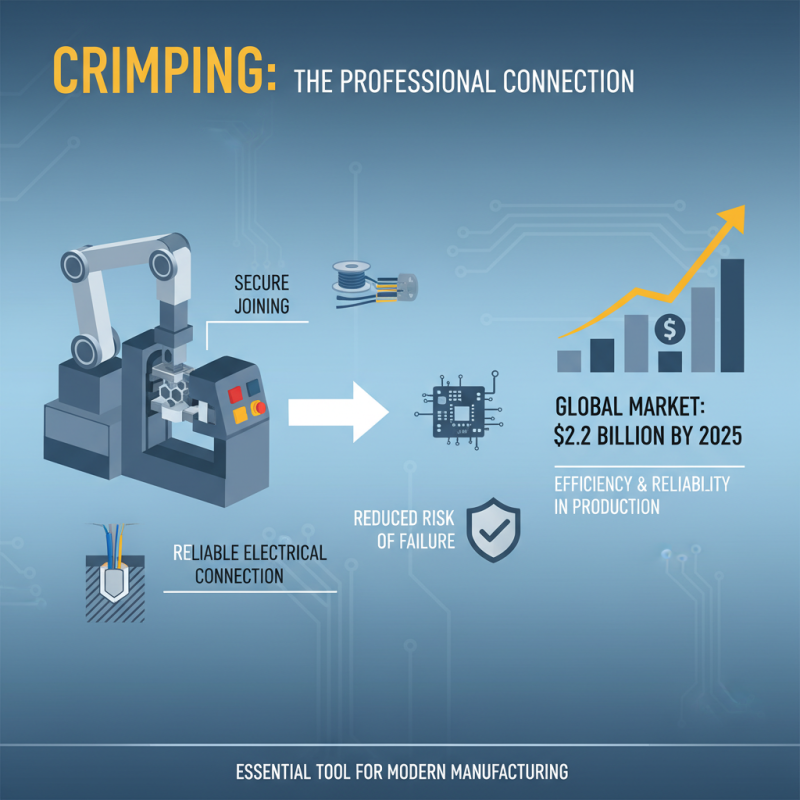

A professional crimping machine is an essential tool used in various industries for joining two pieces of metal or electrical components by deforming one or both to hold the other. These machines are often employed in manufacturing processes involving cables, wires, and connectors. The crimping process can ensure a secure and reliable electrical connection, significantly reducing the risk of failure in electronic systems. According to industry reports, the global crimping machine market is projected to reach USD 2.2 billion by 2025, highlighting the critical role these machines play in ensuring efficiency and reliability in production.

Crimping machines come in various designs and sizes, ranging from hand-held devices suitable for light tasks to heavy-duty machines capable of handling large-scale projects. The operation of a professional crimping machine typically involves inserting the components to be crimped into the machine's jaws, which then apply pressure to create a tight bond. This process can vary depending on the materials being joined, with some requiring specific types of dies or settings for optimal results. Reports indicate that advancements in technology are leading to more precise and automated crimping machines, further enhancing production efficiency.

Tips: When selecting a professional crimping machine, consider the scale of your projects and the materials you'll be working with. It’s crucial to choose a machine that offers adjustable settings to accommodate different wire sizes and types. Regular maintenance is also vital; keeping the machine clean and well-lubricated can significantly extend its lifespan and performance.

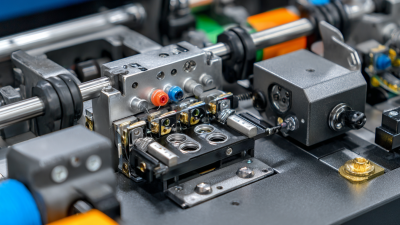

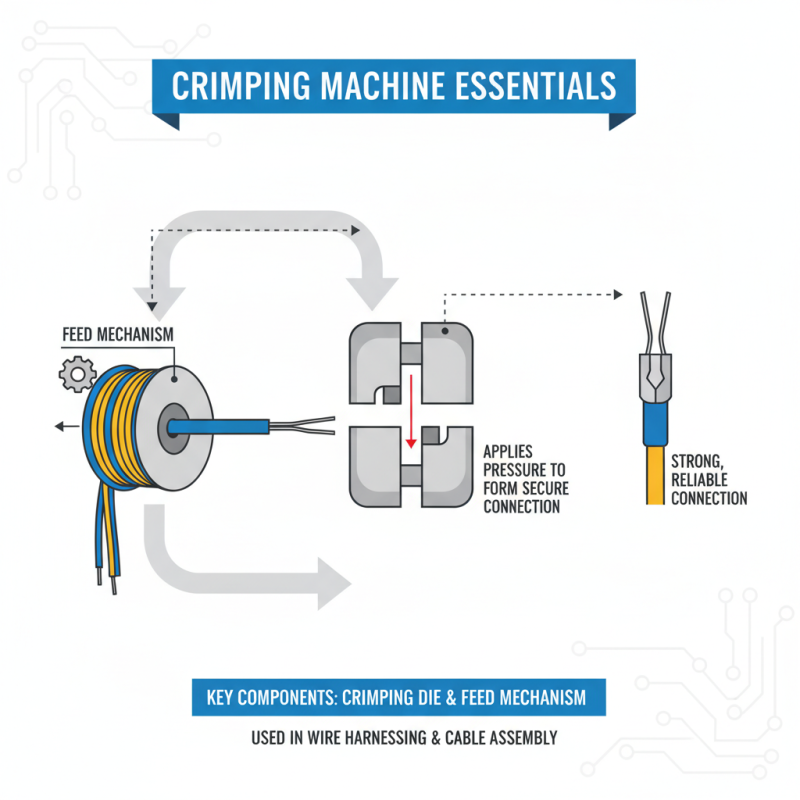

Crimping machines are essential tools used in various industries for creating strong and reliable connections, particularly in wire harnessing and cable assembly. The design of a crimping machine incorporates several key components that contribute to its efficient operation. At the heart of the machine is the crimping die, which determines the shape and size of the crimp. The die engages with the wire and terminal, applying the necessary pressure to form a secure connection. Additionally, a feed mechanism is crucial, allowing for the precise alignment and positioning of the materials being crimped.

The features of crimping machines can vary significantly based on their intended applications. Many modern crimping machines come equipped with digital displays and programmable settings that enable operators to adjust parameters such as crimping force and cycle speed. Safety features, such as emergency stop buttons and protective covers, are also integral to minimize the risk of accidents during operation. Moreover, advanced machines may include sensors for real-time monitoring, ensuring that each connection meets quality standards. This combination of components and features allows professional crimping machines to enhance productivity, maintain high quality, and ensure safety in industrial environments.

The crimping process is a critical technique employed in numerous industries, including telecommunications and electronics, to connect two pieces of metal or plastic in a secure manner. The operation begins with preparing the materials: the wires to be crimped must be stripped of their insulation, revealing the metallic core. This is crucial as effective electrical connections are dependent on the quality of the stripped surface. According to industry reports, improper stripping techniques can lead to failed connections and increased overall costs by up to 30%.

Once the materials are prepped, the crimping machine is calibrated to apply the right amount of force, ensuring a stable and reliable joint. The use of professional crimping machines is paramount as they deliver consistent results, adhering to specified standards in various sectors. A well-executed crimp involves placing a terminal onto the stripped wire and using the machine's mechanism to compress the terminal around the wire. It is essential that the crimped connection meets the specified tensile strength and resistance levels, as defects can lead to catastrophic failures in high-stakes applications. Industry standards suggest that well-executed crimp connections should withstand a minimum pullout force of 4 to 6 pounds for optimal performance. Each phase of the crimping process underscores the significance of precision and consistency in maintaining the quality and reliability of electrical assemblies.

| Step | Description | Tools Needed | Common Applications |

|---|---|---|---|

| 1 | Prepare the materials to be crimped. | Wire cutters, stripping tool | Electrical wiring, cables |

| 2 | Strip insulation from wire ends. | Wire stripper | Connectors for electrical circuits |

| 3 | Insert wire into the connector. | Crimping machine | Network cables, automotive applications |

| 4 | Use the crimping machine to secure connectors. | Professional crimping machine | Communication cables, electronics |

| 5 | Inspect crimped connections for security. | Visual inspection tools | Quality control in manufacturing |

Professional crimping machines are indispensable tools in various industries, enabling precise and efficient joining of materials. These machines are commonly used in electrical, automotive, and manufacturing sectors, where reliable connections are crucial. They excel in creating secure and durable bonds between wires and connectors, hoses and fittings, or cables and terminations, ensuring that systems operate effectively and safely.

One of the primary applications of professional crimping machines is in the electrical industry. They are used to attach connectors to electrical wires, creating strong and conductive links that are resistant to corrosion and wear. In the automotive sector, crimping machines assist in assembling components such as wiring harnesses that are vital for vehicle functionality. Moreover, in manufacturing, these machines facilitate the production of complex assemblies, streamlining the process and reducing downtime.

Tips: When using a professional crimping machine, ensure that you choose the correct die for the size and type of connector you are working with, as this can significantly affect the quality of the crimp. Additionally, regularly maintain your machine to prolong its lifespan and ensure consistent performance. Always verify the crimp quality through testing to prevent any potential failures in your applications.

Maintenance and safety are crucial aspects of operating a professional crimping machine effectively. Regular maintenance not only prolongs the life of the machine but also ensures optimal performance, minimizing the risk of accidents. It is essential to keep the machine clean and free from debris, as accumulated dirt can hinder operation and affect the quality of crimps. Regularly inspect and replace worn-out parts such as blades and dies to maintain consistent results.

When using crimping devices, it is vital to follow safety protocols to prevent injuries. Always wear appropriate protective equipment, including gloves and safety goggles. Ensure that the work area is well-lit and free from potential hazards. Before beginning any crimping tasks, check that all components are securely attached and in good condition. If the machine makes unusual noises or vibrates excessively, cease operation immediately and conduct a thorough inspection.

Tips for effective maintenance include lubricating moving parts regularly and ensuring all connections are tight. Keeping the machine's manual on hand allows for quick reference regarding proper operation and troubleshooting steps. Establishing a routine maintenance schedule can help catch issues early, providing a safer and more efficient working environment.