Leave Your Message

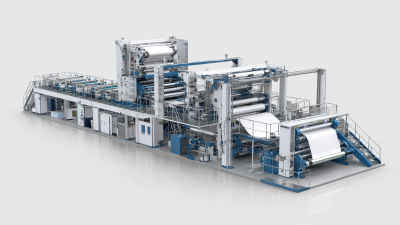

In the ever-evolving landscape of manufacturing, the adoption of cutting-edge technologies has become imperative for enhancing operational efficiency. One of the most transformative advancements in recent years has been the integration of Automatic Nonwoven Equipment into manufacturing processes. These sophisticated machines not only streamline production lines but also improve product quality by ensuring precision and consistency.

As industries increasingly focus on sustainability and cost-effectiveness, Automatic Nonwoven Equipment offers innovative solutions that minimize waste while maximizing output. This article explores how manufacturers can leverage these advanced technologies to revolutionize their operations, highlighting best practices and strategies for implementation. By embracing Automatic Nonwoven Equipment, businesses can stay competitive in a fast-paced market while meeting the growing demand for high-quality nonwoven products.

As industries increasingly focus on sustainability and cost-effectiveness, Automatic Nonwoven Equipment offers innovative solutions that minimize waste while maximizing output. This article explores how manufacturers can leverage these advanced technologies to revolutionize their operations, highlighting best practices and strategies for implementation. By embracing Automatic Nonwoven Equipment, businesses can stay competitive in a fast-paced market while meeting the growing demand for high-quality nonwoven products.

Automation plays a pivotal role in the efficiency of nonwoven manufacturing processes. As the demand for nonwoven fabrics across various industries such as hygiene, medical, and filtration continues to rise, manufacturers are increasingly adopting advanced automatic equipment technologies. These innovations not only streamline production but also enhance product quality by reducing human error and improving precision in fabric creation. Technologies like dry laid, spunbond, and wet laid processes are being optimized through automation, significantly decreasing production times and costs.

Furthermore, the integration of Industry 4.0 principles into nonwoven manufacturing is shaping a smarter, more sustainable future. This shift enables real-time monitoring of production lines, predictive maintenance, and data-driven decision-making, all of which contribute to improved operational efficiencies. Companies are embracing these automated solutions to meet the growing consumer demand for personal hygiene products and sustainable materials. With advanced automation, manufacturers can maintain a competitive edge, ensuring their operations are not only faster but also environmentally responsible.

The manufacturing landscape is undergoing a significant transformation with the integration of advanced automatic nonwoven equipment technologies. Key innovations such as high-velocity carding machines and ultrasonic bonding systems are leading the charge in enhancing production efficiency. According to a report by Smithers Pira, the global nonwoven market is projected to grow to $50 billion by 2025, driven by the rising demand for lightweight, durable materials. These advancements in machinery not only streamline operations but also reduce waste, improving overall sustainability in production processes.

Furthermore, automation in nonwoven manufacturing allows for higher precision and adaptability in production. Technologies such as AI-driven process controls can optimize workflows and minimize downtime, achieving productivity improvements of up to 30%, as indicated in a recent survey by Technavio. The incorporation of smart sensors for real-time monitoring has also demonstrated a reduction in labor costs by approximately 20%, showcasing the economic benefits alongside operational efficiency. Such technological integrations underscore the importance of continuous innovation in maintaining competitiveness in the rapidly evolving nonwoven sector.

| Technology | Description | Efficiency Improvement (%) | Key Advantages |

|---|---|---|---|

| Automated Control Systems | Integration of AI for process monitoring and adjustments | 25% | Reduced human error, optimized production rates |

| High-Speed Spinning Technologies | Advanced spinning methods that increase throughput | 30% | Higher productivity, lower operational costs |

| Smart Quality Control | Real-time defect detection using machine learning algorithms | 20% | Enhanced product quality, fewer returns |

| Energy Efficiency Innovations | Use of sustainable energy solutions in production processes | 15% | Reduced energy costs, compliance with eco-regulations |

| Flexible Automation | Systems that adapt to different product lines quickly | 18% | Reduced setup time, increased versatility |

The implementation of advanced automatic systems in manufacturing nonwoven materials is transforming productivity and efficiency in the industry. According to the report by Smithers Pira, the global nonwoven market is projected to reach $45 billion by 2025, reflecting a compound annual growth rate of 5.3%. To effectively capitalize on this growth, manufacturers must adopt best practices in integrating automation technologies. This includes utilizing real-time data analytics to optimize production lines and reduce downtime. For instance, deploying smart sensors can significantly improve machine monitoring and predictive maintenance, thereby enhancing overall operational efficiency.

Furthermore, integrating advanced automatic systems requires a strategic approach. Manufacturers should prioritize workforce training to ensure that employees are equipped to handle sophisticated equipment and software. A recent survey by the Association of Nonwoven Fabrics Industry (INDA) indicated that companies investing in employee training alongside technology upgrades experience a 20% increase in efficiency. Additionally, leveraging automation not only minimizes labor costs but also enhances product quality through precise control and consistency in manufacturing processes. As the industry continues to evolve, adopting these advanced practices will be crucial for manufacturers aiming to increase their competitive edge in the nonwoven sector.

The integration of advanced automatic nonwoven equipment technologies is fundamentally transforming manufacturing efficiency, particularly in the production of sanitary napkins. In light of recent reports, the evaluation of the impact of these technologies on production costs and quality is becoming increasingly critical. The streamlined processes enabled by innovative equipment not only reduce labor costs but also minimize material wastage, leading to lower overall production expenses. As manufacturers adopt these technologies, they are finding that the initial investment is quickly offset by significant cost savings in the long run.

Moreover, the emphasis on fiber laydown quality in spunbond processes highlights the importance of precision in manufacturing. Simulation experiments, evaluated through sophisticated methodologies such as blocked neural networks, shed light on the cause-and-effect relationships that govern production outcomes. By optimizing these processes, manufacturers can enhance product quality while maintaining competitive pricing. This synergy between technology and quality assurance is crucial for driving sustainable growth in the nonwoven fabric sector, helping companies to meet rising consumer demands effectively and efficiently.

The future of automated nonwoven manufacturing is poised for significant transformation, driven by advancements in technology and increasing market demands. One of the most prominent trends is the integration of smart manufacturing systems, characterized by the use of Internet of Things (IoT) devices. These systems enable real-time data collection and analysis, allowing manufacturers to monitor production processes more closely, optimize operations, and reduce waste. This connectivity facilitates proactive maintenance, minimizing downtime and ensuring higher output efficiency.

Another compelling trend is the rise of artificial intelligence (AI) and machine learning within production lines. AI algorithms can analyze vast amounts of data to identify patterns and predict potential issues before they arise. This predictive capability allows manufacturers to adjust their processes dynamically, ensuring product quality and consistency. Moreover, the implementation of automation in material handling and quality control further increases production speeds and reduces human error. As these technologies evolve, the nonwoven manufacturing industry will not only enhance its efficiency but also improve sustainability through more responsible resource management and innovative recycling methods.