Leave Your Message

The Ring Spinning Machine is a key piece of equipment in the textile industry. Renowned expert Dr. Emily Tran states, “The Ring Spinning Machine revolutionized yarn production.” Her insight highlights the machine's importance in creating high-quality textiles.

This machine operates by twisting fibers together. It produces strong and fine yarn, suitable for various fabrics. Despite its efficiency, the machine requires constant monitoring and maintenance. Small issues can lead to larger problems, affecting production quality.

Each production cycle poses challenges. Workers must ensure the machine functions properly without interruptions. Understanding the Ring Spinning Machine's intricacies is essential for success in textile manufacturing. As manufacturers embrace technology, they must also reflect on sustainability and efficiency within their production processes.

A ring spinning machine is essential in the textile industry. It produces yarn by twisting fibers together. This process creates a smooth and strong thread, ideal for various fabrics. The machine operates by drawing out a continuous strand of fiber and twisting it to form yarn. This method is efficient and widely used across the globe.

According to industry reports, the ring spinning technology accounts for about 75% of the total yarn production worldwide. Despite its efficiency, the process is not without challenges. For instance, maintaining consistent tension on the fibers is critical. Any variation can lead to uneven yarn quality. Moreover, energy consumption is a concern. The spinning process demands significant power, leading to higher production costs.

Challenges in machinery upkeep cannot be overlooked. Regular maintenance is necessary to ensure optimal performance. Delays in repairs can lead to downtime, which affects overall productivity. Analyzing machine data can help identify potential issues early. Improving efficiency is an ongoing effort within the industry.

The mechanism of ring spinning is fascinating. It transforms fibers into yarn through a series of controlled processes. Initially, a roving of fibers is drawn into the machine. This allows precise alignment of the fibers. A feed-in roller guides the roving toward the spinning component.

As the roving enters the ring, it is twisted into yarn. The spindle rotates rapidly, creating tension. This tension draws the fibers tighter together. Accurate adjustments ensure the right thickness of the yarn. However, if the tension is too high, fibers may break. This leads to inconsistency in the final product.

While the process seems straightforward, it requires careful monitoring. Operators must regularly check the machine settings. If they become lax, yarn quality suffers. Adjustments are essential for optimal results. The art of balancing these variables is crucial. It's an ongoing learning experience. Each batch of yarn teaches something new.

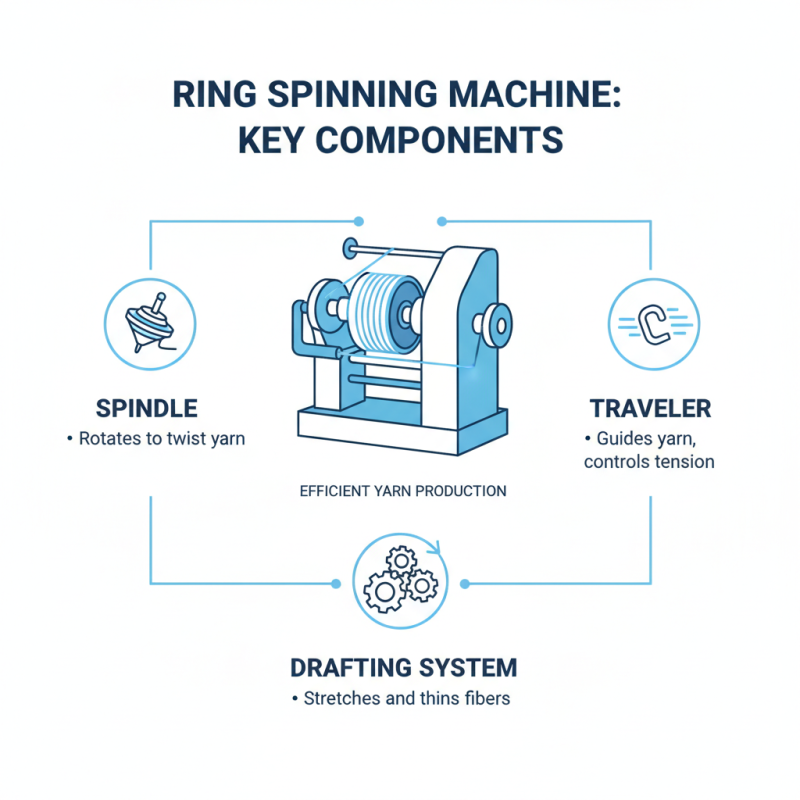

A ring spinning machine is an essential tool in the textile industry. Its key components play critical roles in producing high-quality yarn. The machine consists mainly of the spindle, traveler, and drafting system. Each part works together for efficient yarn production.

The spindle is the heart of the machine. It rotates at high speeds to twist fibers into yarn. The traveler moves around the ring during this process, enabling the spinning of yarn to occur. A well-functioning traveler ensures smooth and consistent yarn quality. However, maintaining the right balance on the spindle can be tricky. Operators sometimes find themselves adjusting settings frequently, which can disrupt the workflow.

The drafting system is vital as well. It stretches the fibers before they twist into yarn, ensuring uniform thickness. An improperly set drafting system can lead to uneven yarn. This inconsistency might create challenges during fabric production. Operators must pay close attention to adjustments. Paying attention to these components can significantly enhance the quality of the final product. Yet, there are moments when oversight can lead to flaws. This is a reminder of the delicate balance in the spinning process.

Ring spinning machines are a staple in the textile industry, known for their efficiency in yarn production. The process begins with fibers being drawn out and twisted into strands. This results in a stronger and smoother yarn. However, achieving the perfect tension and twist can be challenging. Operators need to monitor the machine closely to ensure consistent quality.

One major advantage of ring spinning is its ability to produce high-quality yarn. The finished product often has improved uniformity and strength, which is vital for various textile applications. Additionally, ring spinning allows for better control over the yarn’s fineness. Nonetheless, there are drawbacks. This process can be time-consuming compared to newer methods like rotor spinning. The initial setup may also require skilled technicians to fine-tune the machine.

Production efficiency is another calling card of ring spinning. It can handle large volumes of fiber, reducing lead times and increasing output. However, this efficiency comes with the risk of producing defects if not monitored. Blending fibers properly is necessary to prevent variations in quality. Even with these challenges, many manufacturers continue to rely on ring spinning for its numerous advantages.

The realm of ring spinning technology is evolving rapidly. Innovations focus on enhancing efficiency and sustainability. According to a report by Global Industry Analysts, the global ring spinning machine market is expected to reach $2.3 billion by 2025, growing at a compound annual growth rate of over 6%. This reflects a strong demand for high-quality and cost-effective spinning solutions.

One notable trend is the integration of automation. Machines are now equipped with advanced sensors. These detect irregularities in yarn quality in real-time, reducing waste. Industry experts report that automated systems can increase production speed by 20% while minimizing manual errors. However, this push towards automation raises concerns about job displacement in traditional spinning mills.

Moreover, the focus on sustainability is influencing design. Manufacturers are developing machines that minimize energy consumption and water usage. According to Textile World, innovative designs can reduce energy requirements by as much as 30%. This offers significant long-term savings. Yet, it begs the question: how can companies balance sustainability with profitability? The industry must reflect on these challenges while embracing technological advancements.

| Dimension | Data |

|---|---|

| Spindle Speed (RPM) | 20,000 - 25,000 |

| Production Efficiency (%) | 85 - 90 |

| Energy Consumption (kWh/kg) | 0.1 - 0.14 |

| Noise Level (dB) | 75 - 80 |

| Output per Spindle (kg/h) | 0.5 - 1.5 |

| Common Fiber Types | Cotton, Polyester, Wool |

| Recent Innovations | Automation, IoT Integration, Energy Efficiency Improvements |