Leave Your Message

The Ring Spinning Machine is a vital tool in the textile industry. It transforms raw fibers into high-quality yarn through a unique spinning process. Industry expert Dr. Emily Carter states, "The efficiency of the Ring Spinning Machine revolutionizes yarn production.” Her insights underline the machine's significance.

This machine employs a rotating spindle to twist and draw fibers together. The result is a strong, even yarn, favored in various textile applications. However, while its technology is impressive, operators often overlook maintenance. This can lead to reduced efficiency and quality.

Understanding the Ring Spinning Machine is crucial for manufacturers. It can provide a competitive edge in a demanding market. Yet, the complexity of its operation presents challenges. Some processes may require more training and attention than others. Operators must continually refine their skills to maximize performance.

A ring spinning machine plays a crucial role in the textile industry. It spins fibers into yarn, which is a fundamental component of fabric production. The machine operates by twisting and drawing out fibers, creating a strong and durable yarn. According to a report by Research and Markets, the global ring spinning machine market is projected to grow significantly, driven by the increasing demand for quality textile products.

The components of a ring spinning machine include a delivery mechanism, a spindle, and a ring. The delivery mechanism ensures consistent fiber flow, while the spindle rotates to twist the fibrous material. This process produces fine and even yarn, suitable for various textile applications. Industry data reveals that over 60% of yarn produced worldwide comes from ring spinning, underscoring its importance in manufacturing.

However, this technology is not without its challenges. Maintenance can be costly, and older machines may require frequent repairs. Moreover, the energy consumption of ring spinning is a concern. Recent studies indicate that modern machines can improve efficiency, but many facilities still operate with outdated models. This presents an opportunity for manufacturers to innovate and optimize their spinning processes for better sustainability.

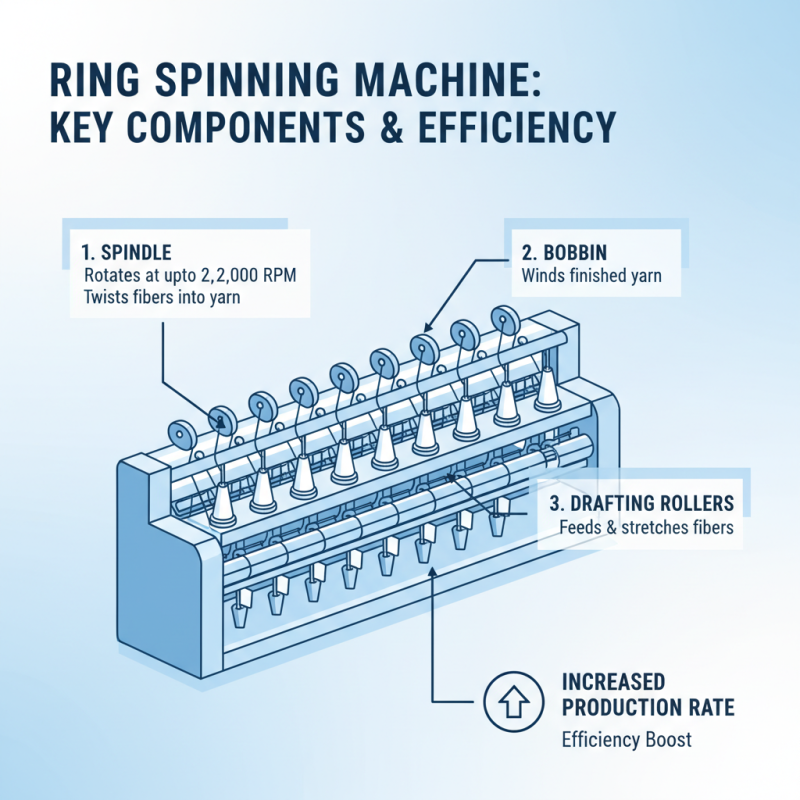

A ring spinning machine is a crucial tool in the textile industry. Understanding its key components can help us appreciate its efficiency and importance. The primary part is the spindle. Spindles rotate at high speeds, enabling fiber twisting. This rotation creates yarn with desired thickness. Reports indicate that spindles can reach speeds of up to 25,000 RPM. This efficiency boosts production rates significantly.

Next, we have the traveler. The traveler moves around the ring and guides the yarn during spinning. Different types of travelers impact the yarn's quality. A study indicated that using optimized traveler designs can reduce flaws in the final product by 30%. Another important component is the drafting system. This system controls fiber alignment before twisting. Proper drafting ensures uniformity in yarn. A miscalibrated drafting system can result in uneven yarn thickness, leading to waste.

Lastly, we cannot overlook the bobbin. The bobbin holds the finished yarn. The bobbin's design affects how easily the yarn is unwound. Some manufacturers report difficulties with bobbin changeovers, affecting overall efficiency. These challenges show that continuous improvements are necessary in this technology. Understanding these components is essential for any textile professional aiming to enhance production quality.

The spinning process begins with raw fibers. These fibers, often cotton or wool, arrive in bales. The bales are opened and the fibers are prepared for spinning. Cleaning and blending are essential steps. The goal is to ensure uniformity in the fibers. Once prepared, the fibers are carded. This transforms the clumps into a continuous web of fibers.

Next, the carded fibers are drawn out. This step aligns the fibers more closely together. It creates a sliver, which is a loose rope of fibers. The sliver is then twisted into yarn. This is where the ring spinning machine comes into play. It pulls the sliver through a series of rollers. These rollers help to control tension and thickness.

As the fibers twist, they form a strong and continuous thread. However, not every attempt is perfect. Sometimes the yarn may have irregularities. These flaws can occur due to fiber characteristics or machine settings. Operators must constantly monitor the process. Adjustments are necessary to refine the yarn. This nuanced process requires both skill and patience. Each step is crucial in determining the final quality of the yarn produced.

Ring spinning machines are known for their versatility in producing various types of yarns. One of the main types is cotton yarn. This yarn is soft and breathable. It is commonly used in everyday clothing and home textiles. The process starts with raw cotton fibers being spun into strands. This allows the fibers to be twisted tightly, creating durable and strong yarn.

Another prominent type produced by these machines is synthetic yarn. Made from materials like polyester and nylon, synthetic yarn offers durability. It is often water-resistant and suitable for outdoor wear. However, the environmental impact of synthetic fibers raises concerns. Many argue that using these materials is not a sustainable choice.

Wool yarn is also created using ring spinning machines. This type is known for its warmth and elasticity. Wool fibers can be tricky to work with, as they require special handling. The delicate balance between twist and tension must be observed. Understanding these nuances is essential for producing quality wool yarn. Each type of yarn has its advantages and drawbacks. This complexity invites constant exploration and refinement in the spinning process.

| Type of Yarn | Fiber Composition | Tensile Strength | Common Applications |

|---|---|---|---|

| Cotton Yarn | 100% Cotton | Moderate | T-shirts, Bed Linen |

| Polyester Yarn | 100% Polyester | High | Activewear, Outdoor Gear |

| Wool Yarn | 100% Wool | Moderate to High | Sweaters, Scarves |

| Blended Yarn | Cotton/Polyester Blend | Moderate | Casual Wear, Home Textiles |

| Silk Yarn | 100% Silk | Low to Moderate | Luxury Garments, Evening Wear |

Ring spinning technology has significant advantages. It offers high production efficiency, making it a favored choice in textile manufacturing. Reports indicate that it can produce up to 30% more yarn per spindle hour compared to other methods. Yarn produced through ring spinning is known for its strength and durability. The process creates a tight twist, enhancing the yarn's ability to withstand stress.

However, there are downsides to consider. The initial setup costs are high, requiring substantial investment in machinery. Maintenance can be complicated, adding to ongoing expenses. Productivity can be affected by the skill level of operators, which varies widely in the industry. Additionally, ring spinning consumes more energy, leading to higher operational costs. Acknowledging these factors is vital for manufacturers deciding on their production methods. Balancing these pros and cons remains a central issue in optimizing yarn production strategies.