Leave Your Message

The textile industry is a vital part of the global economy, generating approximately $995 billion in revenue yearly. A significant contributor to this sector is the Textile Fabric Machine. This technology not only revolutionizes fabric production but also enhances efficiency. According to industry reports, the global textile machinery market is projected to grow at a compound annual growth rate of 4.65% from 2021 to 2026.

Understanding how a Textile Fabric Machine functions is essential for grasping the complexities of fabric manufacturing. These machines automate processes, reducing labor costs while increasing productivity. Yet, the reliance on such technology raises questions about job displacement and sustainability in textile production.

While the advantages of Textile Fabric Machines are clear, their impact on quality and craftsmanship is a topic of ongoing debate. There is a fine line between mass production and unique, artisanal fabric creation. The industry must reflect on these issues to balance innovation and tradition. Only then can we ensure a sustainable future for textile manufacturing that respects both the craft and technological progress.

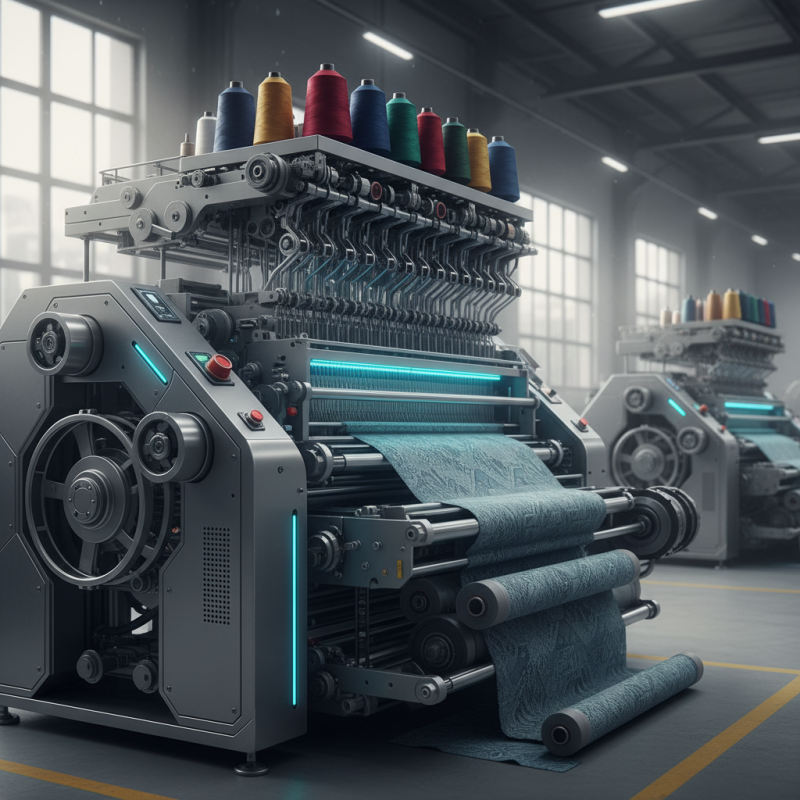

A textile fabric machine is an essential tool in the world of fabric production. It creates various types of fabrics from raw fibers. These machines can weave, knit, or stitch fabric together, depending on their design. Operators feed fibers or yarns into the machine, which does the rest. The intricate mechanics work together to produce high-quality textiles efficiently.

Tips: Always ensure the machine is well-maintained. Regular cleaning can improve its performance. Check for any frayed threads or obstructions before starting. A small issue might disrupt the entire process.

Many who operate these machines find it challenging at times. Understanding the machine's settings and functions is crucial. New operators may struggle with complexities. It takes practice and patience to master the controls. Mistakes can happen, but that's part of learning. Don’t get discouraged, as each error provides valuable lessons.

Tips: Start with simple projects to build your confidence. Using less complicated fabrics can help sharpen your skills. Observation is key; watch seasoned operators to learn their techniques. This can greatly enhance your understanding of the machine’s capabilities.

Textile fabric machines come in various types, each serving unique purposes in fabric production. Spinning machines turn fibers into yarn, a fundamental step in creating textiles. They twist and draw out fibers, ensuring consistent thickness. Meanwhile, weaving machines interlace yarns to form fabrics. This process can create a variety of textures and patterns, enriching the final product.

Knitting machines focus on interlocking yarns, creating stretchable fabrics ideal for garments. These machines enable complex designs without much manual effort. Additionally, printing machines can add intricate designs to fabric, elevating plain textiles into vibrant pieces of art. However, the technology isn't perfect. Sometimes, the prints don’t adhere as well as intended, leading to inconsistencies.

Finishing machines play a vital role as well. They treat fabrics for durability, softness, or water resistance. Despite advancements, achieving the perfect finish can be challenging. One might find that certain fabrics don’t react well to treatments. Innovators must be diligent in refining these processes, as fabric quality directly affects user experience. Each machine type showcases the intricate balance of technology and artistry in the textile industry.

Textile fabric machines are vital in the fabric manufacturing industry. These machines convert raw fibers into finished textile products. Understanding their key components is essential for optimizing production processes.

The primary components of textile fabric machines include spinning units, weaving and knitting machines, and finishing equipment. Spinning units twist fibers into yarn. According to the International Textile Manufacturers Federation (ITMF), about 75% of the global textile production comes from spinning operations. Weaving machines interlace threads to create fabrics. A report by Research and Markets indicated the global weaving machine market is expected to grow at a CAGR of 4.7% by 2025.

Knitting machines serve a different purpose. They loop yarn into knit fabrics. While they enhance production speed, they can be more complex to maintain. Finishing equipment adds properties like water resistance or softness. Despite advancements, many companies struggle with machine downtime. This can lead to lost revenue. Each component's efficiency is crucial for maintaining competitive edge in the textile market.

Investing in high-quality machinery can be beneficial but also carries risks. The initial costs are high, and maintenance can be challenging. Many manufacturers hesitate as technology evolves rapidly. They must weigh benefits against these potential drawbacks.

Textile fabric machines play a crucial role in the textile industry. They automate the process of weaving, knitting, and finishing fabrics. These machines enhance efficiency and consistency in production. Understanding how they work can provide valuable insights into fabric creation.

At the core, textile fabric machines operate on a basic principle: transforming raw materials into usable fabric. Yarn is fed into the machine, where various components perform specific functions. For instance, weaving machines use looms to interlace threads. Knitting machines loop yarn to create stretchable fabrics. These processes involve precise calculations and adjustments to maintain quality.

While these machines are efficient, they are not without flaws. Mechanical breakdowns can occur unexpectedly, disrupting production. Additionally, the dependence on technology may lead to a lack of skilled labor. Innovations continue to emerge, but the need for human oversight remains essential. Balancing automation with craftsmanship is a challenge that the industry faces today.

Textile fabric machines play a crucial role across various industries. The global textile machinery market was valued at approximately $23 billion in 2021. It is projected to grow at a CAGR of 5.4% from 2022 to 2030. This growth indicates a rising demand for efficient production. Textile machines enhance production speed and reduce labor costs significantly. However, many industries still rely on outdated equipment, limiting potential gains.

In the garment sector, technology improves quality and consistency. Research indicates that over 70% of fabric defects originate from manufacturing processes. Advanced textile machines can help address this issue. They allow for precise adjustments throughout production, minimizing errors and waste. Yet, the transition to newer technologies can be slow. Many manufacturers hesitate due to high initial costs.

The sustainability aspect shouldn't be overlooked either. A report from the World Economic Forum states that the textile industry is responsible for 20% of global water pollution. With better machinery, waste management can improve dramatically. Textile machines can optimize resource use. Yet, implementing these changes requires a shift in mindset. Achieving sustainability demands commitment, and not all companies are ready to invest.