Leave Your Message

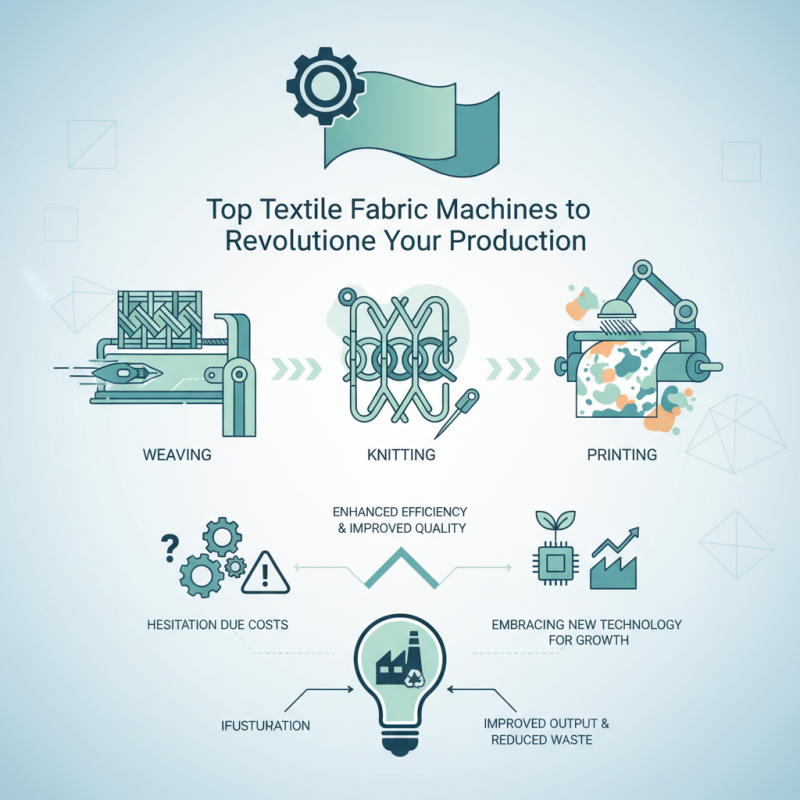

The textile industry is evolving rapidly. Innovations in machinery are changing the landscape of production. Textile fabric machines play a crucial role in this transformation. They enhance efficiency and improve quality in textile manufacturing.

Modern textile fabric machines come in various forms, including weaving, knitting, and printing equipment. Each type offers unique benefits that can elevate production processes. For instance, advanced weaving machines can handle complex designs while increasing speed. However, not all machines are suited for every company. Businesses must carefully consider their specific needs.

Investing in the right textile fabric machine can be a game-changer. Yet, companies sometimes hesitate to upgrade due to costs. The right choice could lead to improved output and reduced waste. Reflecting on past equipment can help identify areas for improvement. While some may resist change, embracing new technology is essential for growth.

The textile industry is evolving rapidly with cutting-edge fabric machines. Recent data suggests that automation in this sector can boost productivity by up to 30%. The implementation of high-speed weaving machines is a key factor driving this trend. These machines can produce intricate patterns at unprecedented speeds, reducing production times significantly.

Additionally, digital printing technology has transformed fabric design. This innovative method allows designers to create complex designs quickly and cost-effectively. A survey from the Fabric Association indicates that 40% of fabric producers are now using digital printing. However, the transition to these technologies is not without challenges. Many manufacturers face difficulties in training staff to operate advanced machinery.

Moreover, there's an ongoing debate about sustainability. While some machines reduce waste, others consume excessive energy. A report highlighted that around 60% of textile firms are concerned about their environmental impact. Therefore, aligning technology advancements with eco-friendly practices remains a critical issue for the industry. The journey toward innovation is essential but requires careful consideration.

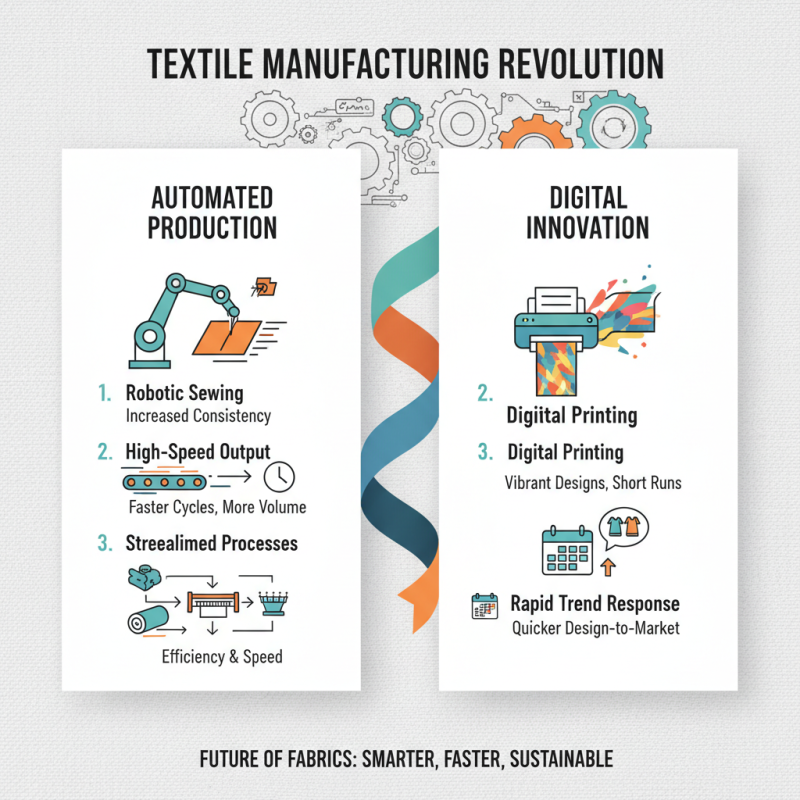

Advancements in technology have significantly transformed textile fabric production. Automated machinery streamlines processes, allowing higher output in less time. For example, sewing robots now handle complex stitching tasks. This reduces human error and increases consistency in production quality. Digital printing technology allows for vibrant patterns and shorter runs. Brands can introduce designs faster, responding to trends more effectively.

However, the reliance on technology comes with its challenges. Maintenance of advanced machines can be costly and time-consuming. Not all facilities may have skilled technicians to troubleshoot problems quickly. Additionally, smaller manufacturers might struggle to compete with larger companies that can invest in the latest machinery. This imbalance raises questions about sustainability in the industry.

Moreover, while technology enhances production efficiency, it may lead to job losses in some areas. Workers may need retraining to keep pace with automation. The shift requires a balance between innovation and workforce integration. Without careful planning, the human element of fabric production could diminish. Many questions remain about how to navigate these changes responsibly.

Textile production is evolving rapidly. Machinery plays a crucial role in this transformation. Weaving, knitting, and finishing techniques are at the forefront of this change. According to recent reports, the global market for textile machinery is projected to reach $33 billion by 2025. This indicates a significant growth, driven by innovation and efficiency.

Weaving machines have become smarter. They enhance productivity and minimize waste. Modern weaving looms can operate at speeds exceeding 1,500 picks per minute. This efficiency may lead to faster turnaround times. However, the initial cost of these machines can be a barrier for small businesses. Some manufacturers still rely on outdated models, missing out on technological advancements.

Knitting machinery is also advancing. Circular knitting machines can produce a variety of fabrics in a single run. They can create seamless and multidimensional products. Yet, many companies struggle with scaling these technologies. Training staff to operate sophisticated machines remains a challenge. Finishing techniques, on the other hand, add value to the fabric. Innovative finishing machinery can enhance durability and appearance. Despite these benefits, the complexity of these processes can lead to inconsistent quality. Manufacturers must continually refine their techniques to meet customer expectations.

| Type of Machinery | Description | Key Features | Applications |

|---|---|---|---|

| Weaving Machines | Used for interlacing yarns to create fabric. | High speed, electronic control, automatic warp feed. | Home textiles, upholstery, clothing. |

| Knitting Machines | Create fabric by interlocking loops of yarn. | Versatile gauge, multi-functionality, programmable. | Apparel, sportswear, flat textiles. |

| Finishing Machines | Enhance the appearance and feel of fabric. | Dyeing, printing, coating options available. | Fashion textiles, technical textiles. |

| Embroidery Machines | Stitch designs onto fabrics. | Multi-needle, automatic thread change, high precision. | Decorative apparel, branded merchandise. |

| Laser Cutting Machines | Cut fabric using laser technology for precision. | High accuracy, minimal waste, fast production. | Fashion design, sample making, mass production. |

The textile industry is rapidly evolving. Innovations in automation are at the forefront, enhancing fabric production efficiency. According to a recent industry report, automated systems can increase productivity by up to 30%. These advancements streamline operations, reducing manual labor and minimizing errors.

Automation technologies, such as robotic sewing and advanced cutting machines, offer precision. They also speed up the production process. However, not all companies are adopting these innovations quickly. Some firms face challenges with integration. Training staff on new systems can be daunting. There’s a need for a culture shift towards embracing technology.

Tips: Consider investing in employee training. This can ease the transition to automated systems. It's crucial to understand that while automation brings efficiency, it also demands a new skill set. Additionally, assess your production flow regularly to identify areas needing automation. This reflection ensures that investments yield the best returns.

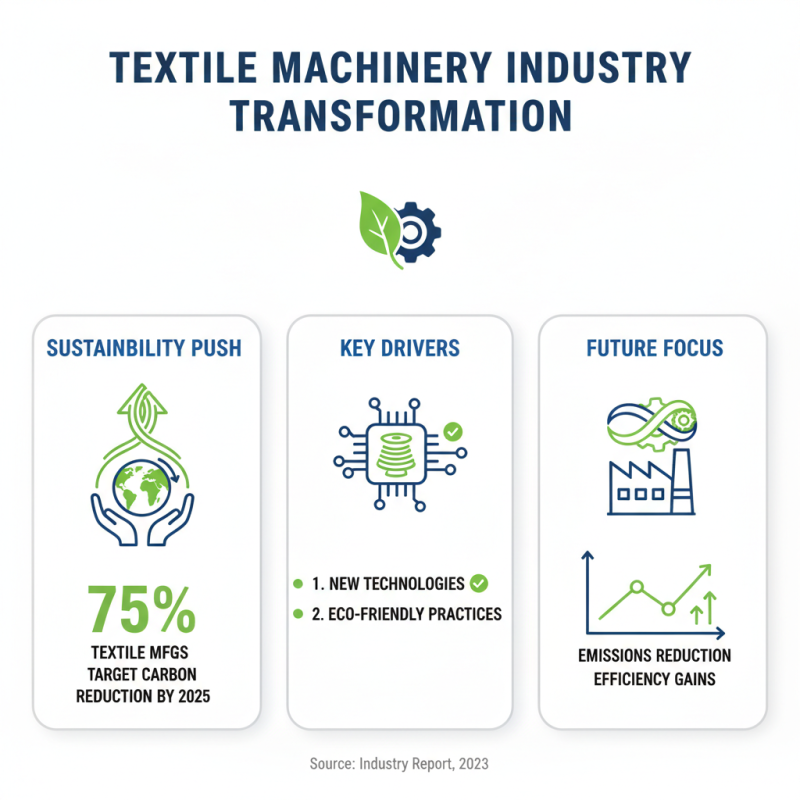

The textile machinery industry is undergoing significant transformations. Sustainable practices are becoming essential. A recent report shows that over 75% of textile manufacturers aim to reduce their carbon footprints by 2025. New technologies are critical in achieving these goals.

Some innovative machines use water-saving techniques. They can cut water usage by up to 50%. Meanwhile, certain textile production processes now incorporate recycled materials. This shift reduces waste and promotes a closed-loop system. However, implementations can be challenging. Many factories struggle with balancing cost and sustainability.

Furthermore, automation in textile machinery helps increase efficiency. According to estimates, productivity can rise by 30% with smart systems. Yet, reliance on technology brings concerns about job loss. Workers may need new skills to thrive in this evolving landscape. Balancing efficiency and human employment is a complex issue. The industry must address these contradictions while moving forward.