Leave Your Message

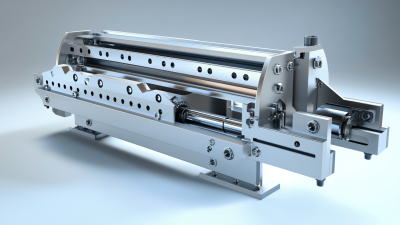

In today's competitive market, investing in a Professional Crimper Machine can drastically improve your business operations. According to a recent report by the Institute of Manufacturing Excellence, companies that utilize advanced crimping technology see a 30% increase in production efficiency. This statistic highlights the importance of modern equipment in maximizing performance.

Industry expert Dr. Jane Thompson states, "A Professional Crimper Machine is not just an upgrade; it's an essential tool for meeting production demands." This quote illustrates how critical such machinery is for businesses striving to maintain quality while keeping pace with consumer expectations.

However, not all businesses realize the potential pitfalls of outdated tools. Relying on basic crimping solutions can lead to errors, wasted materials, and ultimately lost revenue. In contrast, a Professional Crimper Machine can elevate the quality of your end products and reduce operational errors. Embracing this technology is vital for those seeking to thrive in a challenging landscape.

Choosing a professional crimper machine can significantly enhance business operations. These machines drastically improve efficiency in various industries, particularly in manufacturing and construction. According to industry reports, businesses that invest in high-quality crimping equipment see an average productivity increase of 20%. This improvement often translates into reduced labor costs and faster turnaround times.

The precision offered by professional crimpers is noteworthy. Data from recent studies show that improper crimping can lead to a 30% increase in defects. This can result in wasted materials and time, making proficiency crucial. Using a reliable crimper minimizes these risks. It ensures every connection meets industry standards.

However, not every company invests in the best machinery. Some use lower-end models to cut costs. But this often backfires as maintenance and error rectification can become pricier. In fact, around 25% of businesses report higher operational costs due to equipment failures caused by inadequate tools. Quality crimpers deliver dependable performance, leading to long-term savings.

Professional crimper machines offer distinct advantages over DIY options. One major difference is precision. These machines are engineered for accuracy, ensuring each crimp is consistent. This consistency reduces waste and improves the quality of your products. DIY tools, on the other hand, often lack this level of reliability. Inconsistent results can lead to customer dissatisfaction and a damaged reputation.

Another key feature is speed. Professional crimpers are designed to handle high volumes quickly. This efficiency means you can produce more in less time. When deadlines loom, having a reliable machine is crucial. DIY options often require more manual effort and can slow down production.

Tips: Invest in a machine that fits your specific needs. Not every business requires the same functionality. Consider the material you’ll be working with. Sometimes, it’s easy to overlook maintenance. Regular checks can prevent downtime. An occasional inspection can save bucks on repairs down the line. Keep in mind, choosing a professional crimper is an investment. It's not always straightforward, but the long-term benefits often outweigh initial costs.

In today’s competitive market, production efficiency is vital. Quality crimping significantly influences how smoothly operations run. Poor crimping leads to increased downtime, wasted materials, and higher costs. Industry statistics show that businesses using professional crimper machines report a 30% boost in production efficiency. Consistency in crimping can dramatically reduce error rates.

For those evaluating investments in crimping technology, consider the long-term benefits. A reliable crimper reduces the likelihood of defects. This, in turn, enhances your product’s reputation. Over time, the return on investment becomes undeniable. Yet, businesses often overlook the initial learning curve. Training staff on new machinery is crucial but sometimes neglected.

Tips: Always maintain your crimper. Routine checks prevent breakdowns. Document any recurring issues; this helps in troubleshooting. Foster a culture of feedback among your team. Discuss crimping techniques and share improvements. These small adjustments can lead to significant gains. Remember, quality crimping is not just about the machine. It's about how well your team uses it.

Investing in a professional crimper machine can lead to significant long-term savings for businesses. According to industry reports, companies that switch to professional-grade equipment see a 20-30% decrease in operational costs. This reduction results from improved efficiency and the longevity of high-quality machines. Businesses often underestimate downtime caused by inferior tools. Reduced downtime enhances productivity and ultimately boosts profits.

Quality crimping machines also minimize material waste. Reports suggest that using professional-grade tools can lower scrap rates by up to 25%. Less waste means lower raw material costs, directly impacting the bottom line. Moreover, the precision of these machines ensures higher product quality, which can lead to improved customer satisfaction and repeat business. Cost-per-unit calculations show a drastic improvement when using reliable equipment.

Not all businesses initially recognize these savings. Many choose cheaper alternatives, believing they are saving money. However, hidden costs quickly accumulate, including repairs and replacements. A machine that breaks down frequently can derail production schedules, leading to missed deadlines. Ultimately, investing in a professional crimper machine is not just a purchase; it’s a strategic decision that can yield substantial returns over time.

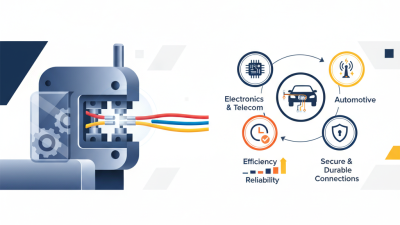

In today's competitive market, the quality and consistency of products are paramount. A professional crimper machine can significantly enhance these aspects. Research indicates that companies using high-quality crimping technologies can improve their product reliability by up to 30%. Consistent crimps lead to better connections, which is fundamental in various industries.

Using a professional machine means achieving precise dimensions every time. This consistency reduces the risk of defects. For instance, improper crimping can lead to up to 20% of product failures in electrical connectors. By investing in a professional crimper, businesses can minimize these risks and improve overall product lifespan.

However, it's not just about the crimper. Continuous training and monitoring are essential. Workers must adapt to new technology and maintenance protocols. A recent study found that 25% of crimping failures are attributed to operator error. This figure highlights the need for a well-rounded approach to quality assurance, not solely reliant on high-tech equipment. Investing in both machines and personnel training is crucial.